Общий каталог OSG 2018 - 2019 - страница 1296

Навигация

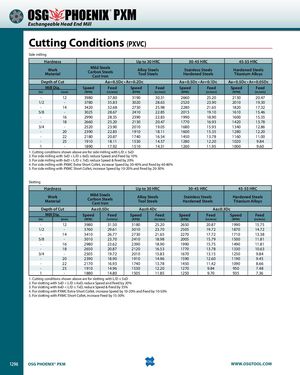

® PXM Exchangeable Head End Mill Cutting Conditions (PXVC) Side milling Hardness Up to 30 HRC 30-45 HRC 45-55 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool Steels Stainless Steels Hardened SteelsHardened SteelsTitanium Alloys Depth of Cut Aa=0.5Dc • Ar=0.2Dc Aa=0.5Dc • Ar=0.1Dc Aa=0.5Dc • Ar=0.05Dc Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed (in) (mm) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) - 12 3980 37.80 3190 30.31 2660 25.20 2130 20.47 1/2 - 3780 35.83 3020 28.63 2520 23.90 2010 19.30 - 14 3420 32.68 2730 25.98 2280 21.65 1820 17.32 5/8 - 3025 28.67 2410 22.85 2015 19.10 1610 15.46 - 16 2990 28.35 2390 22.83 1990 18.90 1600 15.35 - 18 2660 25.20 2130 20.47 1770 16.93 1420 13.78 3/4 - 2520 23.90 2010 19.05 1680 15.93 1340 12.86 - 20 2390 22.83 1910 18.11 1600 15.35 1280 12.20 - 22 2180 20.87 1740 16.54 1450 13.78 1160 11.00 - 25 1910 18.11 1530 14.57 1280 12.20 1020 9.84 1 - 1890 17.92 1510 14.31 1260 11.95 1000 9.60 1. Cutting conditions shown above are for side milling with L/D ≤ 5xD 2. For side milling with 5xD < L/D ≤ 6xD, reduce Speed and Feed by 10% 3. For side milling with 6xD < L/D ≤ 7xD, reduce Speed & Feed by 20% 4. For side milling with PXMC Extra-Short Collet, increase Speed by 30-40% and Feed by 40-80% 5. For side milling with PXMC Short Collet, increase Speed by 10-20% and Feed by 20-30% Slotting Hardness Up to 30 HRC 30-45 HRC 45-55 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool Steels Stainless Steels Hardened SteelsHardened SteelsTitanium Alloys Depth of Cut Aa≤0.5Dc Aa≤0.4Dc Aa≤0.3Dc Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed (in) (mm) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) - 12 3980 31.50 3180 25.20 2650 20.87 1990 15.75 1/2 - 3760 29.61 3010 23.70 2505 19.72 1870 14.72 - 14 3410 26.77 2730 21.65 2270 17.72 1710 13.38 5/8 - 3010 23.70 2410 18.98 2005 15.79 1500 11.81 - 16 2980 23.62 2390 18.90 1990 15.75 1490 11.81 - 18 2650 20.87 2120 16.53 1770 13.78 1330 10.63 3/4 - 2505 19.72 2010 15.83 1670 13.15 1250 9.84 - 20 2390 18.90 1910 14.96 1590 12.60 1190 9.45 - 22 2170 16.93 1740 13.78 1450 11.42 1090 8.66 - 25 1910 14.96 1530 12.20 1270 9.84 950 7.48 1 - 1880 14.80 1505 11.85 1250 9.70 935 7.36 1. Cutting conditions shown above are for slotting with L/D ≤ 5xD 2. For slotting with 5xD < L/D ≤ 6xD, reduce Speed and Feed by 20% 3. For slotting with 6xD < L/D ≤ 7xD, reduce Speed & Feed by 35% 4. For slotting with PXMC Extra-Short Collet, increase Speed by 10-20% and Feed by 10-50% 5. For slotting with PXMC Short Collet, increase Feed by 15-30% 1296 OSG PHOENIX® PXM WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta