Общий каталог OSG 2018 - 2019 - страница 1295

Навигация

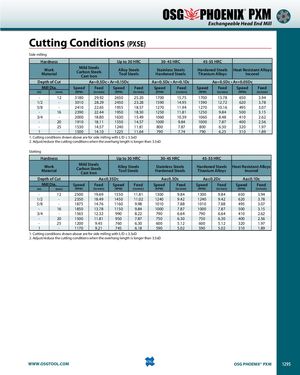

® PXM Exchangeable Head End Mill Cutting Conditions (PXSE) Side milling Hardness Up to 30 HRC 30-45 HRC 45-55 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool SteelsStainless Steels Hardened Steels Heat Resistant AlloysHardened SteelsTitanium AlloysInconel Depth of Cut Aa=0.5Dc • Ar=0.15Dc Aa=0.5Dc • Ar=0.1Dc Aa=0.5Dc • Ar=0.05Dc Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed (in) (mm) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) - 12 3180 29.92 2650 25.20 1700 15.75 1700 13.78 650 3.94 1/2 - 3010 28.29 2450 23.28 1590 14.95 1590 12.72 620 3.78 5/8 - 2410 22.65 1955 18.57 1270 11.94 1270 10.16 495 3.07 - 16 2390 22.44 1950 18.50 1250 11.81 1250 9.84 500 3.15 3/4 - 2000 18.80 1630 15.49 1060 10.39 1060 8.48 410 2.62 - 20 1910 18.11 1550 14.57 1000 9.84 1000 7.87 400 2.56 - 25 1530 14.57 1240 11.81 800 7.87 800 6.30 320 1.97 1 - 1500 14.10 1225 11.64 790 7.74 790 6.25 310 1.89 1. Cutting conditions shown above are for side milling with L/D ≤ 3.5xD 2. Adjust/reduce the cutting conditions when the overhang length is longer than 3.5xD Slotting Hardness Up to 30 HRC 30-45 HRC 45-55 HRC WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool SteelsStainless Steels Hardened Steels Heat Resistant AlloysHardened SteelsTitanium AlloysInconel Depth of Cut Aa≤0.35Dc Aa≤0.3Dc Aa≤0.2Dc Aa≤0.1Dc Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed (in) (mm) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) (RPM) (in/min) - 12 2500 19.69 1550 11.81 1300 9.84 1300 9.84 650 3.94 1/2 - 2350 18.49 1450 11.02 1240 9.42 1240 9.42 620 3.78 5/8 - 1875 14.76 1160 9.98 1010 7.88 1010 7.88 495 3.07 - 16 1850 13.78 1150 9.84 1000 7.87 1000 7.87 500 3.15 3/4 - 1565 12.32 990 8.22 790 6.64 790 6.64 410 2.62 - 20 1500 11.81 950 7.87 750 6.30 750 6.30 400 2.56 - 25 1200 9.45 760 6.30 600 5.12 600 5.12 320 1.97 1 - 1170 9.21 745 6.18 590 5.02 590 5.02 310 1.89 1. Cutting conditions shown above are for side milling with L/D ≤ 3.5xD 2. Adjust/reduce the cutting conditions when the overhang length is longer than 3.5xD WWW.OSGTOOL.COM OSG PHOENIX® PXM 1295

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta