Общий каталог OSG 2018 - 2019 - страница 1259

Навигация

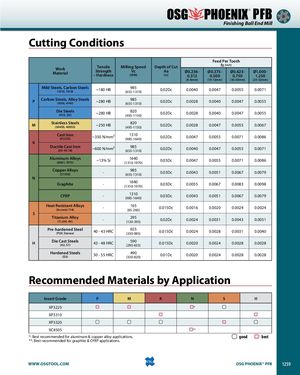

® PFB Finishing Ball End Mill Cutting Conditions Feed Per Tooth WorkMaterial Tensile Milling Speed Depth of Cut fz (in/t)StrengthVcAaØ0.236-Ø0.375-Ø0.625-Ø1.000-– Hardness(SFM)(in)0.3120.5000.7501.250 (6-8mm) (10-12mm) (16-20mm) (25-32mm) Mild Steels, Carbon Steels(1010, 1018)~180 HB 985(655-1310) 0.02Dc 0.0040 0.0047 0.0055 0.0071 P Carbon Steels, Alloy Steels(1050, 4140)~280 HB 985(655-1310) 0.02Dc 0.0028 0.0040 0.0047 0.0055 Die Steels(H13, D2) ~280 HB 820(495-1150) 0.02Dc 0.0028 0.0040 0.0047 0.0055 M Stainless Steels(304SS, 420SS)~250 HB 820(495-1150) 0.02Dc 0.0028 0.0047 0.0055 0.0067 Cast Iron(FC250) ~350 N/mm² 1310(985-1640) 0.02Dc 0.0047 0.0055 0.0071 0.0086 K Ductile Cast Iron(60-40-18) ~600 N/mm² 985(655-1310) 0.02Dc 0.0040 0.0047 0.0055 0.0071 Aluminum Alloys(6061, 7075) ~13% Si 1640(1310-1970) 0.03Dc 0.0047 0.0055 0.0071 0.0086 Copper Alloys(C1100) - 985(655-1310) 0.03Dc 0.0043 0.0051 0.0067 0.0079 N Graphite - 1640(1310-1970) 0.03Dc 0.0055 0.0067 0.0083 0.0098 CFRP - 1310(985-1640) 0.03Dc 0.0043 0.0051 0.0067 0.0079 Heat Resistant Alloys(Inconel 718) - 165(65-260) 0.015Dc 0.0016 0.0020 0.0024 0.0024 S Titanium Alloy(Ti-6Al-4V) - 295(130-395) 0.02Dc 0.0024 0.0031 0.0043 0.0051 Pre-hardened Steel(P20, Stavax)40 - 43 HRC 655(330-985) 0.015Dc 0.0024 0.0028 0.0031 0.0040 H Die Cast Steels(A2, S7) 43 - 48 HRC 590(295-655) 0.015Dc 0.0020 0.0024 0.0028 0.0028 Hardened Steels(D2) 50 - 55 HRC 490(330-820) 0.01Dc 0.0020 0.0024 0.0028 0.0028 Recommended Materials by Application Insert Grade P M K N S H XP3225 * XP3310 XP3320 XC4505 ** *: Best recommended for aluminum & copper alloy applications. good best **: Best recommended for graphite & CFRP applications. WWW.OSGTOOL.COM OSG PHOENIX® PFB 1259

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta