Общий каталог OSG 2018 - 2019 - страница 1111

Навигация

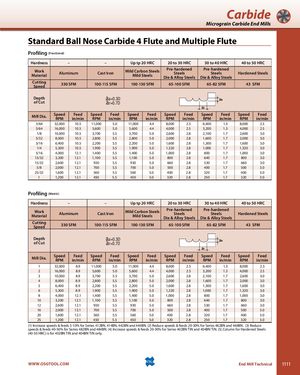

Carbide Micrograin Carbide End Mills Standard Ball Nose Carbide 4 Flute and Multiple Flute Profiling (Fractional) Hardness – – Up tp 20 HRC 20 to 30 HRC 30 to 40 HRC 40 to 50 HRC WorkMaterial Aluminum Cast Iron Mild Carbon SteelsMild SteelsPre-hardenedSteelsDie & Alloy SteelsPre-hardenedSteelsDie & Alloy SteelsHardened Steels CuttingSpeed 330 SFM 100-115 SFM 100-130 SFM 65-100 SFM 65-82 SFM 43 SFM Depthof Cut aaar==00..73DD Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 3/64 32,000 10.5 11,000 5.0 11,000 4.4 8,000 2.5 6,400 1.3 8,000 2.5 5/64 16,000 10.5 5,600 5.0 5,600 4.4 4,000 2.5 3,200 1.3 4,000 2.5 1/8 10,000 10.5 3,700 5.5 3,700 5.0 2,600 2.8 2,100 1.7 2,600 3.0 5/32 8,000 10.5 2,800 5.5 2,800 5.0 2,000 2.8 1,600 1.7 2,000 3.0 3/16 6,400 10.5 2,200 5.5 2,200 5.0 1,600 2.8 1,300 1.7 1,600 3.0 1/4 5,300 10.5 1,900 5.5 1,900 5.0 1,320 2.8 1,000 1.7 1,320 3.0 5/16 4,000 12.1 1,400 5.5 1,400 5.0 1,000 2.8 800 1.7 1,000 3.0 13/32 3,200 12.1 1,100 5.5 1,100 5.0 800 2.8 640 1.7 800 3.0 15/32 2,600 12.1 930 5.5 930 5.0 660 2.8 530 1.7 660 3.0 5/8 2,000 12.1 700 5.5 700 5.0 500 2.8 400 1.7 500 3.0 25/32 1,600 12.1 560 5.5 560 5.0 400 2.8 320 1.7 400 3.0 1 1,200 12.1 450 5.5 450 5.0 320 2.8 250 1.7 320 3.0 Profiling (Metric) Hardness – – Up tp 20 HRC 20 to 30 HRC 30 to 40 HRC 40 to 50 HRC WorkMaterial Aluminum Cast Iron Mild Carbon SteelsMild SteelsPre-hardenedSteelsDie & Alloy SteelsPre-hardenedSteelsDie & Alloy SteelsHardened Steels CuttingSpeed 330 SFM 100-115 SFM 100-130 SFM 65-100 SFM 65-82 SFM 43 SFM Depthof Cut aaar==00..73DD Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min 1 32,000 8.9 11,000 5.0 11,000 4.4 8,000 2.5 6,400 1.3 8,000 2.5 2 16,000 8.9 5,600 5.0 5,600 4.4 4,000 2.5 3,200 1.3 4,000 2.5 3 10,000 8.9 3,700 5.5 3,700 5.0 2,600 2.8 2,100 1.7 2,600 3.0 4 8,000 8.9 2,800 5.5 2,800 5.0 2,000 2.8 1,600 1.7 2,000 3.0 5 6,400 8.9 2,200 5.5 2,200 5.0 1,600 2.8 1,300 1.7 1,600 3.0 6 5,300 8.9 1,900 5.5 1,900 5.0 1,320 2.8 1,000 1.7 1,320 3.0 8 4,000 12.1 1,400 5.5 1,400 5.0 1,000 2.8 800 1.7 1,000 3.0 10 3,200 12.1 1,100 5.5 1,100 5.0 800 2.8 640 1.7 800 3.0 12 2,600 12.1 930 5.5 930 5.0 660 2.8 530 1.7 660 3.0 16 2,000 12.1 700 5.5 700 5.0 500 2.8 400 1.7 500 3.0 20 1,600 12.1 560 5.5 560 5.0 400 2.8 320 1.7 400 3.0 25 1,200 12.1 450 5.5 450 5.0 320 2.8 250 1.7 320 3.0 (1) Increase speeds & feeds 5-10% for Series 412BN, 414BN, 442BN and 444BN. (2) Reduce speeds & feeds 20-30% for Series 462BN and 464BN. (3) Reduce speeds & feeds 40-50% for Series 482BN and 484BN. (4) Increase speeds & feeds 20-30% for Series 402BN TiN and 404BN TiN. (5) Column for Hardened Steels (40-50 HRC) is for 402BN TiN and 404BN TiN only. WWW.OSGTOOL.COM End Mill Technical 1111

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta