Общий каталог OSG 2018 - 2019 - страница 1099

Навигация

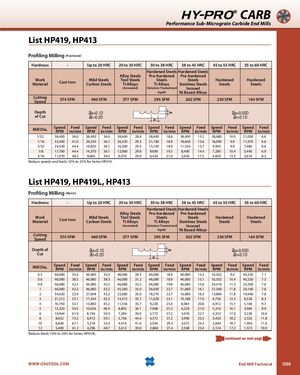

HY-PRO® CARB Performance Sub-Micrograin Carbide End Mills List HP419, HP413 Profiling Milling (Fractional) Hardness – Up to 20 HRC 20 to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC 55 to 60 HRC Hardened Steels Hardened Steels Alloy Steels Pre-hardened Pre-hardened WorkMaterial Cast Iron Mild Steels Tool SteelsCarbon SteelsTi AlloysSteels Steels Hardened HardenedTi AlloysStainless SteelsSteelsSteels (Annealed) (Solution Treated and Inconel Aged) Ni Based Alloys CuttingSpeed 574 SFM 460 SFM 377 SFM 295 SFM 262 SFM 230 SFM 164 SFM Depthof Cut aaar==00..21DD aaar==00..015DD Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min 1/32 38,400 36.0 38,400 36.0 38,400 28.8 38,400 18.6 38,400 13.2 28,680 10.0 21,000 6.6 1/16 32,400 41.0 29,230 36.1 26,520 29.3 21,180 18.9 18,640 13.6 16,090 9.9 11,970 6.6 3/32 24,540 44.4 19,820 36.1 16,300 29.4 13,140 18.9 11,550 13.7 9,950 9.9 7,480 6.6 1/8 17,760 44.4 14,370 36.1 12,060 29.8 9,690 19.5 8,490 14.4 7,280 10.4 5,440 6.9 3/16 11,970 48.3 9,660 39.4 8,070 29.9 6,420 21.0 5,650 17.5 4,830 13.3 3,610 8.3 Reduce speeds and feeds 10% to 25% for Series HP419. List HP419, HP419L, HP413 Profiling Milling (Metric) Hardness – Up to 20 HRC 20 to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC 55 to 60 HRC Hardened Steels Hardened Steels Alloy Steels Pre-hardened Pre-hardened WorkMaterial Cast Iron Mild Steels Tool SteelsCarbon SteelsTi AlloysSteels Steels Hardened HardenedTi AlloysStainless SteelsSteelsSteels (Annealed) (Solution Treated and Inconel Aged) Ni Based Alloys CuttingSpeed 574 SFM 460 SFM 377 SFM 295 SFM 262 SFM 230 SFM 164 SFM Depth ofCut aaar==00..21DD aaar==00..015DD Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min 0.5 46,080 35.4 46,080 35.4 46,080 28.3 46,080 18.0 46,080 14.2 55,032 9.4 40,320 7.1 0.6 46,080 38.3 46,080 38.3 46,080 31.2 46,080 18.9 46,080 15.1 55,032 10.4 40,320 7.3 0.8 46,080 42.5 46,080 42.5 46,080 33.5 46,080 19.8 46,080 15.6 34,416 11.3 25,200 7.6 1 46,080 43.2 46,080 43.2 45,360 35.0 36,000 22.7 31,680 16.1 27,360 11.8 20,160 7.8 2 34,020 52.9 27,648 43.2 22,680 35.0 18,276 22.7 16,080 16.3 13,884 11.8 10,440 7.8 3 21,312 53.1 17,244 43.2 14,472 35.7 11,628 23.1 10,188 17.0 8,736 12.3 6,528 8.3 4 16,740 53.1 13,800 43.2 11,556 35.7 9,228 25.0 8,064 20.8 6,912 15.1 5,160 9.7 5 13,320 59.5 10,656 48.4 8,892 36.1 7,068 25.3 6,228 21.0 5,316 16.1 3,984 9.9 6 10,944 61.9 8,736 50.3 7,284 39.0 5,772 27.2 5,076 22.7 4,332 17.0 3,228 10.6 8 8,652 73.2 6,912 59.1 5,736 44.4 4,572 31.2 3,996 25.5 3,420 18.2 2,532 11.8 10 6,648 67.1 5,316 53.4 4,416 41.6 3,504 29.3 3,072 24.3 2,640 18.7 1,956 11.6 12 5,400 61.2 4,296 48.7 3,612 39.0 2,868 27.4 2,508 23.4 2,124 17.2 1,572 10.9 Reduce feeds 10% to 20% for Series HP419L. WWW.OSGTOOL.COM End Mill Technical 1099

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta