Общий каталог OSG 2018 - 2019 - страница 1098

Навигация

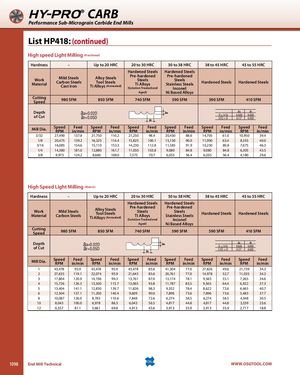

HY-PRO® CARB Performance Sub-Micrograin Carbide End Mills List HP418: (continued) High speed Light Milling (Fractional) Hardness – Up to 20 HRC 20 to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC Hardened Steels Hardened Steels WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsTool SteelsTi Alloys (Annealed)Pre-hardenedSteelsTi Alloys(Solution Treated andPre-hardenedSteelsStainless SteelsInconelHardened SteelsHardened Steels Aged) Ni Based Alloys CuttingSpeed 980 SFM 850 SFM 740 SFM 590 SFM 590 SFM 410 SFM Depthof Cut aaar==00..0052DD aa ar D < 5/320.02D0.05D5/32 < D0.13”0.05D Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/min 3/32 27,490 137.8 21,750 110.2 21,250 98.4 20,450 88.6 14,705 61.0 10,950 39.4 1/8 20,475 139.2 16,325 114.4 15,825 100.1 15,150 90.0 11,000 63.4 8,355 40.0 3/16 16,085 154.6 15,110 153.3 14,230 112.8 11,585 91.9 10,230 80.8 7,675 46.3 1/4 14,380 181.0 12,880 161.7 11,050 103.8 9,080 84.8 9,080 84.8 6,305 43.5 3/8 9,975 124.2 8,660 108.0 7,575 70.7 6,035 56.4 6,035 56.4 4,180 29.6 High Speed Light Milling (Metric) Hardness – Up to 20 HRC 20 to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC Hardened Steels Hardened Steels WorkMaterial Mild SteelsCarbon SteelsAlloy SteelsTool SteelsTi Alloys (Annealed)Pre-hardenedSteelsTi Alloys(Solution Treated andPre-hardenedSteelsStainless SteelsInconelHardened SteelsHardened Steels Aged) Ni Based Alloys CuttingSpeed 980 SFM 850 SFM 740 SFM 590 SFM 590 SFM 410 SFM Depthof Cut aaar==00..0052DD aa ar D < 5/320.02D0.05D5/32 < D0.13”0.05D Mill Dia. SpeedRPM Feedin/minSpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/minSpeedRPM Feedin/min SpeedRPM Feedin/min 1 43,478 95.9 43,478 95.9 43,478 85.6 41,304 77.0 27,826 49.6 21,739 34.3 2 27,635 119.1 22,074 95.9 21,643 85.6 20,761 77.0 14,978 52.7 11,035 34.3 3 17,804 120.9 14,196 99.3 13,761 87.0 13,174 78.1 9,565 55.1 7,265 34.6 4 15,726 126.3 13,500 115.7 13,065 93.8 11,787 83.5 9,565 64.4 6,922 37.3 5 13,404 141.1 12,830 139.7 11,826 98.3 9,352 78.4 8,622 72.6 6,465 40.7 6 12,504 157.1 11,200 140.4 9,609 90.0 7,896 73.6 7,896 73.6 5,483 37.7 8 10,087 126.0 8,783 110.6 7,848 72.6 6,274 58.5 6,274 58.5 4,348 30.5 10 8,043 100.0 6,978 86.3 6,043 56.5 4,817 44.8 4,817 44.8 3,339 23.6 12 6,557 81.1 5,661 69.8 4,913 45.6 3,913 35.9 3,913 35.9 2,717 18.8 1098 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta