Общий каталог OSG 2018 - 2019 - страница 1056

Навигация

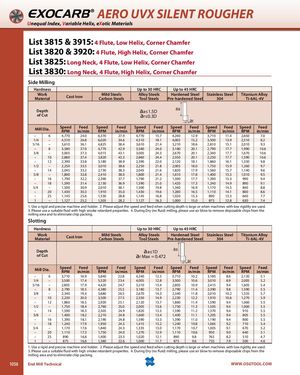

EXOCARB® AERO UVX SILENT ROUGHER Unequal Index, Variable Helix, eXotic Materials List 3815 & 3915: 4 Flute, Low Helix, Corner Chamfer List 3820 & 3920: 4 Flute, High Helix, Corner Chamfer List 3825: Long Neck, 4 Flute, Low Helix, Corner Chamfer List 3830: Long Neck, 4 Flute, High Helix, Corner Chamfer Side Milling Hardness Up to 30 HRC Up to 45 HRC WorkMaterial Cast Iron Mild Steels Alloy Steels Hardened Steel Stainless Steel Titanium AlloyCarbon SteelsTool SteelsPre-hardened Steel304Ti-6AL-4V Depth aa≤1.5D of Cut ar≤0.3D Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min – 6 4,770 24.0 6,370 27.9 4,770 15.7 4,240 12.9 3,710 11.4 2,650 7.0 1/4 – 4,510 26.8 6,020 34.6 4,510 18.1 4,005 15.2 3,500 13.9 2,510 8.2 5/16 – 3,610 36.1 4,825 38.4 3,610 21.4 3,210 18.6 2,810 15.1 2,010 9.3 – 8 3,580 37.0 4,770 42.9 3,580 24.0 3,180 20.1 2,790 17.7 1,990 10.6 3/8 – 3,005 37.3 4,015 43.1 3,005 24.3 2,670 20.1 2,340 17.7 1,670 10.6 – 10 2,860 37.4 3,820 43.3 2,860 24.4 2,550 20.1 2,230 17.7 1,590 10.6 – 12 2,390 33.8 3,180 38.9 2,390 22.0 2,120 18.1 1,860 16.1 1,330 9.8 1/2 – 2,250 33.5 3,010 38.6 2,250 21.8 2,005 18.0 1,750 15.9 1,260 9.7 – 14 2,045 33.2 2,730 38.3 2,045 21.6 1,820 17.9 1,560 15.7 1,140 9.6 5/8 – 1,800 32.8 2,410 38.0 1,800 21.4 1,610 17.8 1,400 15.5 1,010 9.5 – 16 1,790 32.2 2,390 37.7 1,790 21.2 1,590 17.7 1,390 15.3 990 9.4 – 18 1,590 31.4 2,130 36.9 1,590 21.0 1,420 17.3 1,240 14.9 890 9.1 3/4 – 1,500 30.9 2,010 36.1 1,500 19.8 1,340 16.9 1,170 14.5 840 8.8 – 20 1,430 30.3 1,910 35.0 1,430 19.6 1,280 16.5 1,110 14.1 800 8.6 – 25 1,145 25.6 1,530 28.8 1,145 16.8 1,020 15.3 890 13.3 640 7.7 1 – 1,127 25.2 1,505 28.2 1,127 16.3 1,000 15.0 875 12.8 630 7.4 1. Use a rigid and precise machine and holder. 2. Please adjust the speed and feed when cutting depth is large or when machines with low rigidity are used. 3. Please use a suitable fluid with high smoke retardant properites. 4. During Dry (no fluid) milling, please use air blow to remove disposable chips from the milling area and to eliminate chip packing. Slotting Hardness Up to 30 HRC Up to 45 HRC WorkMaterial Cast Iron Mild Steels Alloy Steels Hardened Steel Stainless Steel Titanium AlloyCarbon SteelsTool SteelsPre-hardened Steel304Ti-6AL-4V Depth aa≤1D of Cut ar Max = 0.472 Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min – 6 3,710 16.9 5,840 22.8 4,240 12.5 3,710 10.2 3,180 8.6 2,120 5.1 1/4 – 3,500 17.4 5,520 23.4 4,005 12.8 3,500 10.6 3,010 8.9 2,005 5.2 5/16 – 2,805 17.9 4,420 24.7 3,210 13.4 2,805 10.9 2,415 9.4 1,605 5.4 – 8 2,790 18.5 4,380 25.5 3,180 13.7 2,790 11.4 2,390 9.8 1,590 5.5 3/8 – 2,340 19.4 3,680 26.5 2,670 14.3 2,340 11.8 2,010 10.2 1,335 5.7 – 10 2,230 20.0 3,500 27.5 2,550 14.9 2,230 12.2 1,910 10.6 1,270 5.9 – 12 1,860 18.5 2,920 25.1 2,120 13.7 1,860 11.4 1,590 9.4 1,060 5.5 1/2 – 1,750 18.4 2,760 25.0 2,005 13.6 1,750 11.3 1,505 9.4 1,000 5.5 – 14 1,590 18.3 2,505 24.9 1,820 13.5 1,590 11.2 1,370 9.4 910 5.5 5/8 – 1,400 18.2 2,210 24.8 1,600 13.4 1,400 11.1 1,205 9.4 805 5.5 – 16 1,390 18.1 2,190 24.8 1,590 13.3 1,390 11.0 1,190 9.4 800 5.5 – 18 1,240 17.9 1,950 24.5 1,415 13.2 1,240 10.8 1,065 9.2 710 5.4 3/4 – 1,170 17.6 1,840 24.3 1,335 13.0 1,170 10.7 1,005 9.1 670 5.2 – 20 1,110 17.3 1,750 24.0 1,270 12.9 1,110 10.6 950 9.0 640 5.1 – 25 890 16.8 1,400 23.3 1,020 12.1 890 9.8 765 8.2 510 4.7 1 – 875 16.6 1,380 22.6 1,000 11.7 875 9.6 755 7.9 500 4.6 1. Use a rigid and precise machine and holder. 2. Please adjust the speed and feed when cutting depth is large or when machines with low rigidity are used. 3. Please use a suitable fluid with high smoke retardant properites. 4. During Dry (no fluid) milling, please use air blow to remove disposable chips from the milling area and to eliminate chip packing. 1056 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta