Общий каталог OSG 2018 - 2019 - страница 1055

Навигация

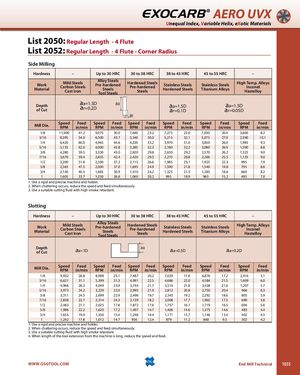

EXOCARB® AERO UVX Unequal Index, Variable Helix, eXotic Materials List 2050: Regular Length - 4 Flute List 2052: Regular Length - 4 Flute - Corner Radius Side Milling Hardness – Up to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC – WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsPre-hardenedSteelsTool SteelsHardened SteelsPre-hardenedSteelsStainless SteelsHardened SteelsStainless SteelsTitanium AlloysHigh Temp. AlloysInconelHastelloy Depthof Cut aa=1.5Dar=0.2D aa=1.5Dar=0.1D aa=1.5Dar=0.05D Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min 1/8 11,900 41.2 9,075 30.0 7,640 23.2 7,275 23.0 7,030 20.4 3,600 8.2 3/16 8,395 54.0 6,500 43.7 5,540 30.0 5,215 32.1 5,075 27.9 2,590 10.1 1/4 6,420 60.0 4,965 44.6 4,220 33.2 3,970 31.0 3,850 26.0 1,985 9.3 5/16 5,135 62.0 4,000 43.8 3,385 32.3 3,180 32.2 3,080 26.9 1,590 8.8 3/8 4,280 59.5 3,330 43.0 2,820 29.8 2,650 29.2 2,570 26.2 1,325 9.0 7/16 3,670 59.4 2,855 42.4 2,420 29.5 2,270 28.8 2,200 25.5 1,135 9.0 1/2 3,200 51.8 2,500 37.2 2,115 26.6 1,985 25.1 1,925 22.3 995 7.9 5/8 2,565 47.5 2,000 37.0 1,695 24.9 1,590 21.8 1,540 19.8 795 8.6 3/4 2,140 40.5 1,665 30.9 1,410 24.2 1,325 21.5 1,285 18.6 660 8.2 1 1,605 33.7 1,250 26.6 1,060 20.2 995 18.9 965 15.2 495 7.0 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. Slotting Hardness – Up to 30 HRC 30 to 38 HRC 38 to 45 HRC 45 to 55 HRC – WorkMaterial Mild SteelsCarbon SteelsCast IronAlloy SteelsPre-hardenedSteelsTool SteelsHardened SteelsPre-hardenedSteelsStainless SteelsHardened SteelsStainless SteelsTitanium AlloysHigh Temp. AlloysInconelHastelloy Depthof Cut aa=1D aa=0.5D aa=0.2D Mill Dia. Speed Feed Speed Feed Speed Feed Speed Feed Speed Feed Speed FeedRPMin/minRPMin/minRPMin/minRPMin/minRPMin/minRPMin/min 1/8 9,932 26.8 8,098 25.1 7,487 20.2 7,029 17.6 6,876 17.2 2,414 5.1 3/16 6,621 31.1 5,399 31.3 4,991 22.5 4,686 22.0 4,584 21.5 1,609 6.0 1/4 4,966 28.3 4,049 23.9 3,744 21.7 3,514 21.8 3,438 21.0 1,207 5.7 5/16 3,973 24.2 3,239 22.0 2,995 21.9 2,812 20.8 2,750 20.4 966 6.3 3/8 3,311 24.5 2,699 22.9 2,496 19.7 2,343 19.2 2,292 18.6 805 5.9 7/16 2,838 22.7 2,314 24.3 2,139 18.2 2,008 17.7 1,965 17.5 690 5.8 1/2 2,483 21.1 2,025 17.8 1,872 17.6 1,757 16.7 1,719 16.5 604 5.6 5/8 1,986 22.2 1,620 17.2 1,497 14.7 1,406 14.6 1,375 14.6 483 4.4 3/4 1,655 19.9 1,350 15.4 1,248 14.4 1,171 13.7 1,146 13.4 402 4.5 1 1,242 17.8 1,012 14.7 936 12.4 879 11.2 860 9.3 302 4.2 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. 4. When length of the tool extension from the machine is long, reduce the speed and feed. WWW.OSGTOOL.COM End Mill Technical 1055

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta