Общий каталог OSG 2018 - 2019 - страница 1006

Навигация

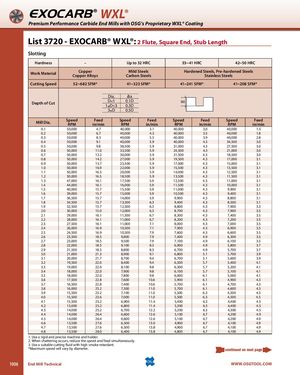

EXOCARB® WXL® Premium Performance Carbide End Mills with OSG’s Proprietary WXL® Coating List 3720 - EXOCARB® WXL®: 2 Flute, Square End, Stub Length Slotting Hardness – Up to 32 HRC 33~41 HRC 42~50 HRC Work Material CopperCopper Alloys Mild SteelsCarbon Steels Hardened Steels, Pre-hardened SteelsStainless Steels Cutting Speed 52~682 SFM* 41~323 SFM* 41~241 SFM* 41~208 SFM* Dia. aa Depth of Cut D<1 0.1D1≤D<30.3D 3≤D 0.5D Mill Dia. SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min SpeedRPM Feedin/min 0.1 50,000 4.7 40,000 3.1 40,000 3.0 40,000 1.5 0.2 50,000 6.7 40,000 4.3 40,000 3.5 40,000 1.8 0.3 50,000 8.3 40,000 5.5 40,000 3.9 40,000 2.8 0.4 50,000 9.1 40,000 5.9 40,000 4.3 34,500 3.0 0.5 50,000 9.8 38,500 5.9 31,000 4.3 27,500 3.0 0.6 50,000 11.0 33,500 5.9 24,500 4.3 21,000 3.0 0.7 50,000 12.2 30,000 5.9 21,500 4.3 18,500 3.0 0.8 50,000 14.2 27,000 5.9 19,500 4.3 17,000 3.1 0.9 50,000 15.7 23,500 5.9 17,000 4.3 15,000 3.1 1.0 50,000 16.9 22,000 5.9 15,500 4.3 13,500 3.1 1.1 50,000 16.5 20,000 5.9 14,000 4.3 12,500 3.1 1.2 50,000 16.5 18,500 5.9 13,500 4.3 11,500 3.1 1.3 47,000 16.1 17,500 5.9 12,500 4.3 11,000 3.1 1.4 44,000 16.1 16,000 5.9 11,500 4.3 10,000 3.1 1.5 40,000 15.7 15,500 5.9 11,000 4.3 9,900 3.1 1.6 39,000 15.7 15,000 5.9 10,500 4.3 9,400 3.1 1.7 36,500 15.7 14,000 5.9 9,900 4.3 8,800 3.1 1.8 34,500 15.7 13,500 6.3 9,400 4.3 8,500 3.1 1.9 32,500 15.7 12,500 6.3 8,800 4.3 7,900 3.3 2.0 30,000 15.0 12,000 6.3 8,700 4.3 7,900 3.5 2.1 29,000 16.1 11,500 6.7 8,300 4.3 7,400 3.5 2.2 28,000 16.1 11,000 6.7 8,200 4.3 7,200 3.5 2.3 27,500 16.1 11,000 7.1 8,000 4.3 7,000 3.5 2.4 26,000 16.9 10,500 7.1 7,900 4.3 6,900 3.5 2.5 24,500 16.9 10,500 7.9 7,600 4.3 6,600 3.5 2.6 23,500 18.5 9,800 7.9 7,400 4.9 6,300 3.5 2.7 23,000 18.5 9,500 7.9 7,100 4.9 6,100 3.5 2.8 22,000 18.5 9,100 8.3 6,900 4.9 5,800 3.7 2.9 21,500 18.5 8,800 8.3 6,700 4.9 5,700 3.7 3.0 21,000 21.3 8,900 9.1 6,800 5.1 5,700 3.9 3.1 20,000 21.7 8,700 9.4 6,700 5.1 5,600 3.9 3.2 19,500 22.0 8,400 9.4 6,500 5.7 5,400 4.1 3.3 19,000 22.0 8,100 9.8 6,300 5.7 5,200 4.1 3.4 18,000 22.0 7,900 9.8 6,100 5.7 5,100 4.1 3.5 18,000 22.0 7,800 9.8 6,000 6.1 5,000 4.1 3.6 17,500 22.8 7,600 10.6 5,900 6.1 4,900 4.3 3.7 16,500 22.8 7,400 10.6 5,700 6.1 4,700 4.3 3.8 16,000 23.2 7,300 11.0 5,700 6.1 4,600 4.3 3.9 15,500 23.2 7,100 11.0 5,500 6.3 4,500 4.3 4.0 15,500 23.6 7,000 11.0 5,500 6.3 4,500 4.5 4.1 15,500 25.2 6,900 11.4 5,400 6.3 4,400 4.5 4.2 15,000 25.2 6,800 11.4 5,300 6.3 4,400 4.5 4.3 14,000 25.2 6,700 12.2 5,200 6.3 4,300 4.5 4.4 14,000 26.4 6,600 12.6 5,100 6.7 4,200 4.9 4.5 14,000 26.4 6,600 12.6 5,100 6.7 4,200 4.9 4.6 13,500 27.6 6,500 13.0 4,900 6.7 4,100 4.9 4.7 13,500 27.6 6,500 13.8 4,900 6.7 4,100 4.9 4.8 13,500 28.0 6,400 13.8 4,800 6.7 4,100 4.9 1. Use a rigid and precise machine and holder. 2. When chattering occurs, reduce the speed and feed simultaneously. 3. Use a suitable cutting fluid with high smoke retardant. *Maximum speed will vary by diameter. 1006 End Mill Technical WWW.OSGTOOL.COM

Общий каталог OSG русский

Общий каталог OSG русский Общий каталог Somta

Общий каталог Somta