Общий каталог Osawa 2018 - страница 641

Навигация

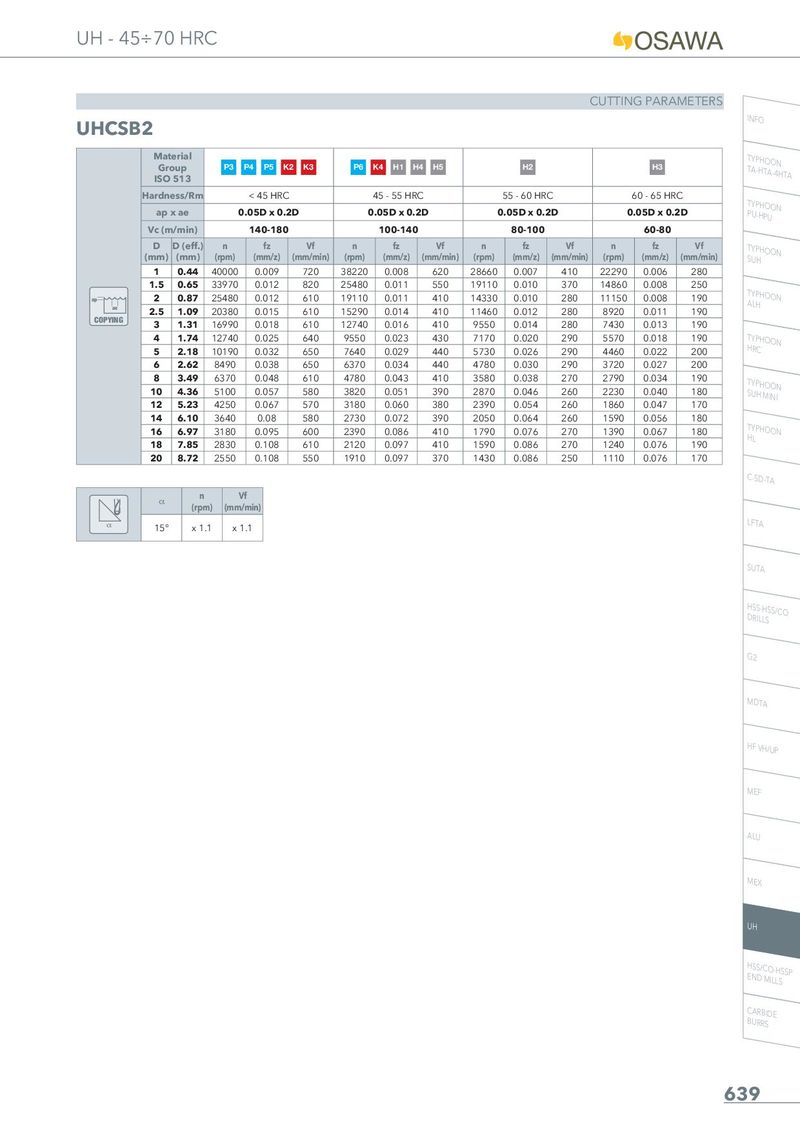

UH - 45÷70 HRC CUTTING PARAMETERS UHCSB2 INFO Material TTYAP-HHTOAO-4NHTA Group P3 P4 P5 K2 K3 P6 K4 H1 H4 H5 H2 H3 ISO 513 Hardness/Rm < 45 HRC 45 - 55 HRC 55 - 60 HRC 60 - 65 HRC TPYUP-HHPOUON ap x ae 0.05D x 0.2D 0.05D x 0.2D 0.05D x 0.2D 0.05D x 0.2D Vc (m/min) 140-180 100-140 80-100 60-80 D D (eff.) n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 1 0.44 40000 0.009 720 38220 0.008 620 28660 0.007 410 22290 0.006 280 1.5 0.65 33970 0.012 820 25480 0.011 550 19110 0.010 370 14860 0.008 250 TAYLPHHOON ap 2 0.87 25480 0.012 610 19110 0.011 410 14330 0.010 280 11150 0.008 190 ae 2.5 1.09 20380 0.015 610 15290 0.014 410 11460 0.012 280 8920 0.011 190 COPYING 3 1.31 16990 0.018 610 12740 0.016 410 9550 0.014 280 7430 0.013 190 4 1.74 12740 0.025 640 9550 0.023 430 7170 0.020 290 5570 0.018 190 THYRPCHOON 5 2.18 10190 0.032 650 7640 0.029 440 5730 0.026 290 4460 0.022 200 6 2.62 8490 0.038 650 6370 0.034 440 4780 0.030 290 3720 0.027 200 8 3.49 6370 0.048 610 4780 0.043 410 3580 0.038 270 2790 0.034 190 TSUYPHHMOIONIN 10 4.36 5100 0.057 580 3820 0.051 390 2870 0.046 260 2230 0.040 180 12 5.23 4250 0.067 570 3180 0.060 380 2390 0.054 260 1860 0.047 170 14 6.10 3640 0.08 580 2730 0.072 390 2050 0.064 260 1590 0.056 180 16 6.97 3180 0.095 600 2390 0.086 410 1790 0.076 270 1390 0.067 180 THYLPHOON 18 7.85 2830 0.108 610 2120 0.097 410 1590 0.086 270 1240 0.076 190 20 8.72 2550 0.108 550 1910 0.097 370 1430 0.086 250 1110 0.076 170 C-SD-TA _ n Vf (rpm) (mm/min) _ 15° x 1.1 x 1.1 LFTA SUTA HDSRSIL-LHSSS/CO G2 MDTA HF VH/UP MEF ALU MEX UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 639

Общий каталог Osawa 2021

Общий каталог Osawa 2021