Общий каталог Osawa 2018 - страница 637

Навигация

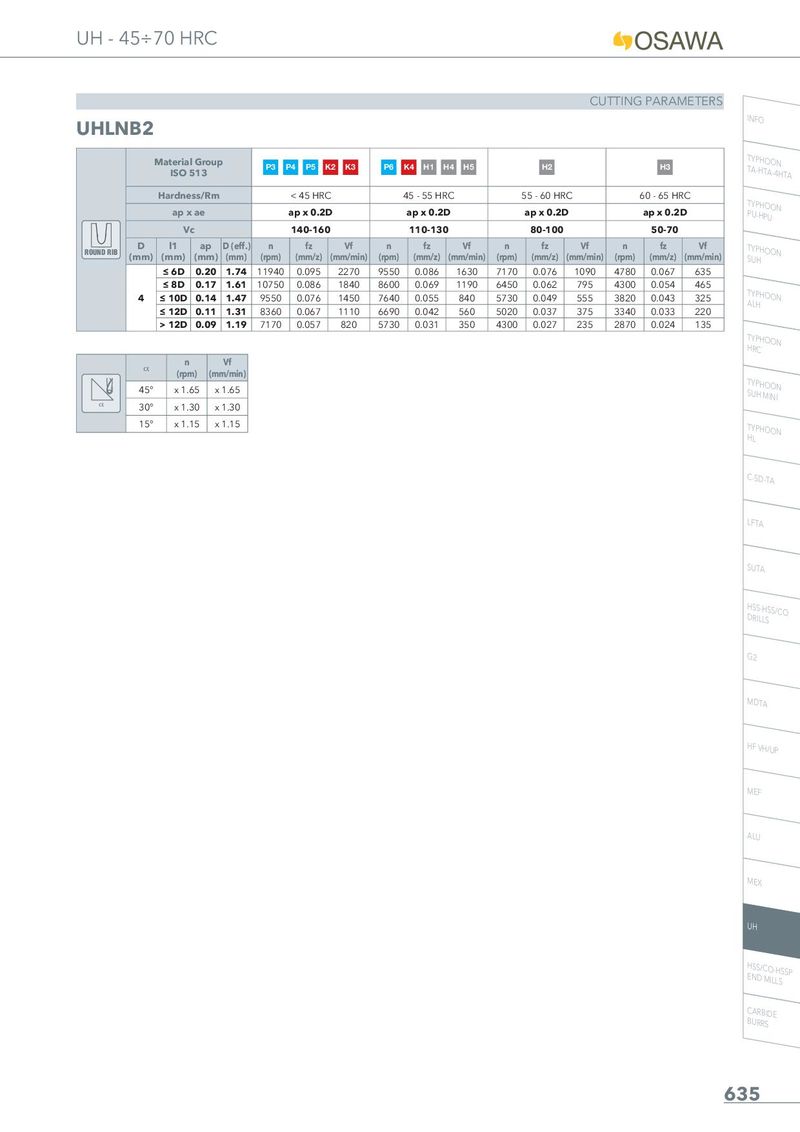

UH - 45÷70 HRC CUTTING PARAMETERS UHLNB2 INFO Material Group P3 P4 P5 K2 K3 P6 K4 H1 H4 H5 H2 H3 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm < 45 HRC 45 - 55 HRC 55 - 60 HRC 60 - 65 HRC TPYUP-HHPOUON ap x ae ap x 0.2D ap x 0.2D ap x 0.2D ap x 0.2D Vc 140-160 110-130 80-100 50-70 ROUND RIB D l1 ap D (eff.) n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (mm) (mm) (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) ≤ 6D 0.20 1.74 11940 0.095 2270 9550 0.086 1630 7170 0.076 1090 4780 0.067 635 ≤ 8D 0.17 1.61 10750 0.086 1840 8600 0.069 1190 6450 0.062 795 4300 0.054 465 TAYLPHHOON 4 ≤ 10D 0.14 1.47 9550 0.076 1450 7640 0.055 840 5730 0.049 555 3820 0.043 325 ≤ 12D 0.11 1.31 8360 0.067 1110 6690 0.042 560 5020 0.037 375 3340 0.033 220 > 12D 0.09 1.19 7170 0.057 820 5730 0.031 350 4300 0.027 235 2870 0.024 135 THYRPCHOON _ n Vf (rpm) (mm/min) TSUYPHHMOIONIN 45° x 1.65 x 1.65 _ 30° x 1.30 x 1.30 15° x 1.15 x 1.15 THYLPHOON C-SD-TA LFTA SUTA HDSRSIL-LHSSS/CO G2 MDTA HF VH/UP MEF ALU MEX UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 635

Общий каталог Osawa 2021

Общий каталог Osawa 2021