Общий каталог Osawa 2018 - страница 636

Навигация

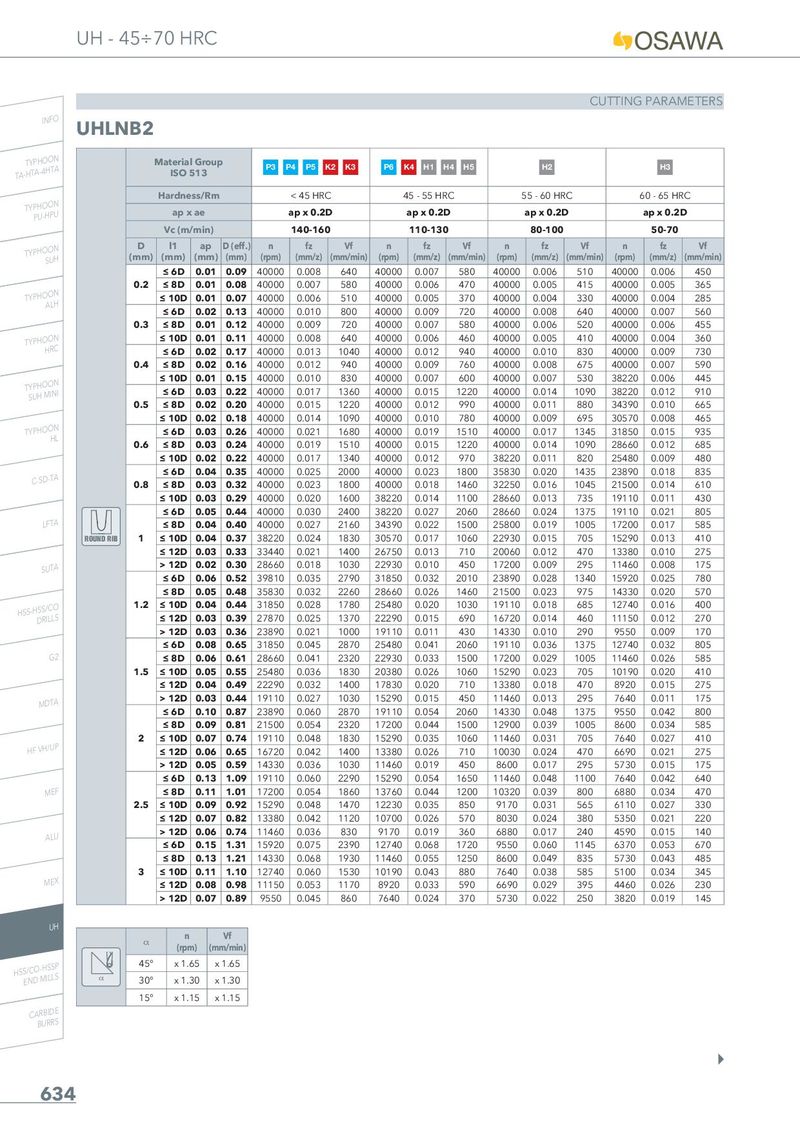

UH - 45÷70 HRC CUTTING PARAMETERS INFO UHLNB2 TA-THYTPAH-4OHOTNA Material Group P3 P4 P5 K2 K3 P6 K4 H1 H4 H5 H2 H3 ISO 513 Hardness/Rm < 45 HRC 45 - 55 HRC 55 - 60 HRC 60 - 65 HRC TYPPHUO-HOPNU ap x ae ap x 0.2D ap x 0.2D ap x 0.2D ap x 0.2D Vc (m/min) 140-160 110-130 80-100 50-70 TYPHOSOUNH D l1 ap D (eff.) n fz Vf n fz Vf n fz Vf n fz Vf (mm) (mm) (mm) (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) ≤ 6D 0.01 0.09 40000 0.008 640 40000 0.007 580 40000 0.006 510 40000 0.006 450 0.2 ≤ 8D 0.01 0.08 40000 0.007 580 40000 0.006 470 40000 0.005 415 40000 0.005 365 TYPHOAOLNH ≤ 10D 0.01 0.07 40000 0.006 510 40000 0.005 370 40000 0.004 330 40000 0.004 285 ≤ 6D 0.02 0.13 40000 0.010 800 40000 0.009 720 40000 0.008 640 40000 0.007 560 0.3 ≤ 8D 0.01 0.12 40000 0.009 720 40000 0.007 580 40000 0.006 520 40000 0.006 455 TYPHOHORNC ≤ 10D 0.01 0.11 40000 0.008 640 40000 0.006 460 40000 0.005 410 40000 0.004 360 ≤ 6D 0.02 0.17 40000 0.013 1040 40000 0.012 940 40000 0.010 830 40000 0.009 730 0.4 ≤ 8D 0.02 0.16 40000 0.012 940 40000 0.009 760 40000 0.008 675 40000 0.007 590 TSYUPHHOMOINNI ≤ 10D 0.01 0.15 40000 0.010 830 40000 0.007 600 40000 0.007 530 38220 0.006 445 ≤ 6D 0.03 0.22 40000 0.017 1360 40000 0.015 1220 40000 0.014 1090 38220 0.012 910 0.5 ≤ 8D 0.02 0.20 40000 0.015 1220 40000 0.012 990 40000 0.011 880 34390 0.010 665 ≤ 10D 0.02 0.18 40000 0.014 1090 40000 0.010 780 40000 0.009 695 30570 0.008 465 TYPHOOHNL ≤ 6D 0.03 0.26 40000 0.021 1680 40000 0.019 1510 40000 0.017 1345 31850 0.015 935 0.6 ≤ 8D 0.03 0.24 40000 0.019 1510 40000 0.015 1220 40000 0.014 1090 28660 0.012 685 ≤ 10D 0.02 0.22 40000 0.017 1340 40000 0.012 970 38220 0.011 820 25480 0.009 480 C-SD-TA ≤ 6D 0.04 0.35 40000 0.025 2000 40000 0.023 1800 35830 0.020 1435 23890 0.018 835 0.8 ≤ 8D 0.03 0.32 40000 0.023 1800 40000 0.018 1460 32250 0.016 1045 21500 0.014 610 ≤ 10D 0.03 0.29 40000 0.020 1600 38220 0.014 1100 28660 0.013 735 19110 0.011 430 ≤ 6D 0.05 0.44 40000 0.030 2400 38220 0.027 2060 28660 0.024 1375 19110 0.021 805 LFTA ≤ 8D 0.04 0.40 40000 0.027 2160 34390 0.022 1500 25800 0.019 1005 17200 0.017 585 ROUND RIB 1 ≤ 10D 0.04 0.37 38220 0.024 1830 30570 0.017 1060 22930 0.015 705 15290 0.013 410 ≤ 12D 0.03 0.33 33440 0.021 1400 26750 0.013 710 20060 0.012 470 13380 0.010 275 SUTA > 12D 0.02 0.30 28660 0.018 1030 22930 0.010 450 17200 0.009 295 11460 0.008 175 ≤ 6D 0.06 0.52 39810 0.035 2790 31850 0.032 2010 23890 0.028 1340 15920 0.025 780 ≤ 8D 0.05 0.48 35830 0.032 2260 28660 0.026 1460 21500 0.023 975 14330 0.020 570 HSS-HDSSR/ILCLOS 1.2 ≤ 10D 0.04 0.44 31850 0.028 1780 25480 0.020 1030 19110 0.018 685 12740 0.016 400 ≤ 12D 0.03 0.39 27870 0.025 1370 22290 0.015 690 16720 0.014 460 11150 0.012 270 > 12D 0.03 0.36 23890 0.021 1000 19110 0.011 430 14330 0.010 290 9550 0.009 170 ≤ 6D 0.08 0.65 31850 0.045 2870 25480 0.041 2060 19110 0.036 1375 12740 0.032 805 G2 ≤ 8D 0.06 0.61 28660 0.041 2320 22930 0.033 1500 17200 0.029 1005 11460 0.026 585 1.5 ≤ 10D 0.05 0.55 25480 0.036 1830 20380 0.026 1060 15290 0.023 705 10190 0.020 410 ≤ 12D 0.04 0.49 22290 0.032 1400 17830 0.020 710 13380 0.018 470 8920 0.015 275 MDTA > 12D 0.03 0.44 19110 0.027 1030 15290 0.015 450 11460 0.013 295 7640 0.011 175 ≤ 6D 0.10 0.87 23890 0.060 2870 19110 0.054 2060 14330 0.048 1375 9550 0.042 800 ≤ 8D 0.09 0.81 21500 0.054 2320 17200 0.044 1500 12900 0.039 1005 8600 0.034 585 2 ≤ 10D 0.07 0.74 19110 0.048 1830 15290 0.035 1060 11460 0.031 705 7640 0.027 410 HF VH/UP ≤ 12D 0.06 0.65 16720 0.042 1400 13380 0.026 710 10030 0.024 470 6690 0.021 275 > 12D 0.05 0.59 14330 0.036 1030 11460 0.019 450 8600 0.017 295 5730 0.015 175 ≤ 6D 0.13 1.09 19110 0.060 2290 15290 0.054 1650 11460 0.048 1100 7640 0.042 640 MEF ≤ 8D 0.11 1.01 17200 0.054 1860 13760 0.044 1200 10320 0.039 800 6880 0.034 470 2.5 ≤ 10D 0.09 0.92 15290 0.048 1470 12230 0.035 850 9170 0.031 565 6110 0.027 330 ≤ 12D 0.07 0.82 13380 0.042 1120 10700 0.026 570 8030 0.024 380 5350 0.021 220 ALU > 12D 0.06 0.74 11460 0.036 830 9170 0.019 360 6880 0.017 240 4590 0.015 140 ≤ 6D 0.15 1.31 15920 0.075 2390 12740 0.068 1720 9550 0.060 1145 6370 0.053 670 ≤ 8D 0.13 1.21 14330 0.068 1930 11460 0.055 1250 8600 0.049 835 5730 0.043 485 3 ≤ 10D 0.11 1.10 12740 0.060 1530 10190 0.043 880 7640 0.038 585 5100 0.034 345 MEX ≤ 12D 0.08 0.98 11150 0.053 1170 8920 0.033 590 6690 0.029 395 4460 0.026 230 > 12D 0.07 0.89 9550 0.045 860 7640 0.024 370 5730 0.022 250 3820 0.019 145 UH _ n Vf (rpm) (mm/min) HSSE/NCDO-MHISLSLPS 45° x 1.65 x 1.65 _ 30° x 1.30 x 1.30 15° x 1.15 x 1.15 CARBIDE BURRS 634

Общий каталог Osawa 2021

Общий каталог Osawa 2021