Общий каталог Osawa 2018 - страница 613

Навигация

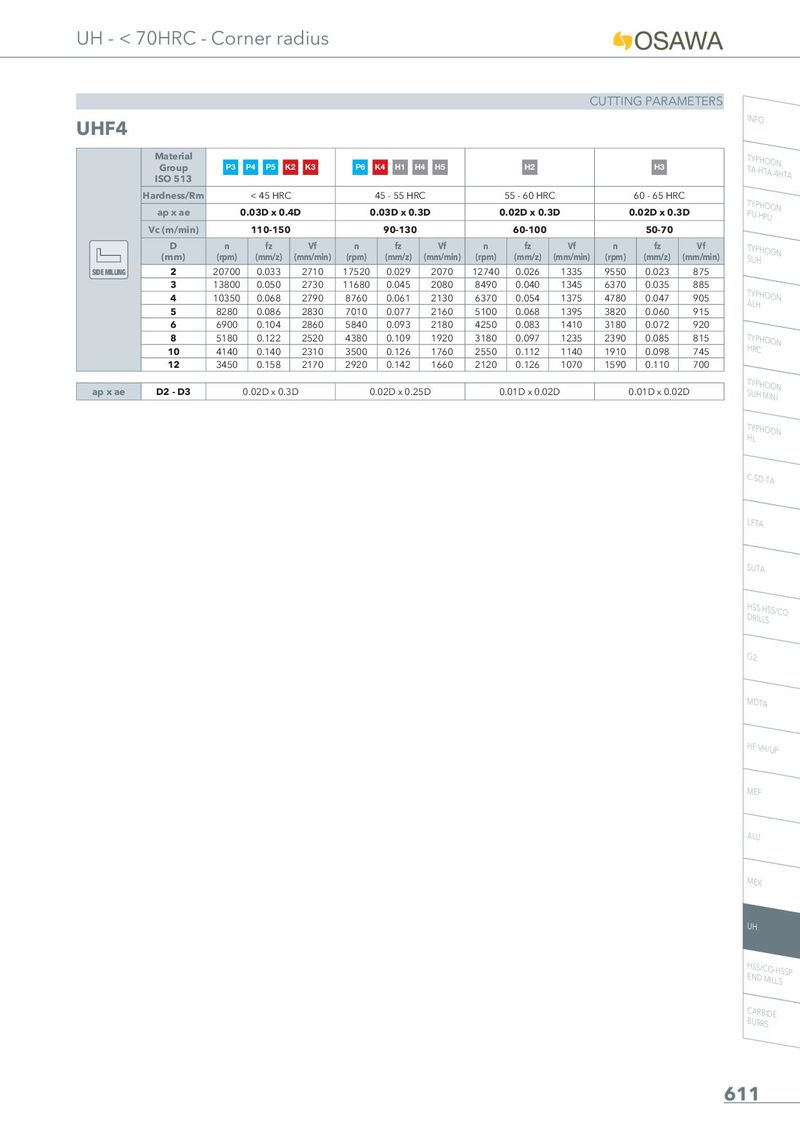

UH - < 70HRC - Corner radius CUTTING PARAMETERS UHF4 INFO Material TTYAP-HHTOAO-4NHTA Group P3 P4 P5 K2 K3 P6 K4 H1 H4 H5 H2 H3 ISO 513 Hardness/Rm < 45 HRC 45 - 55 HRC 55 - 60 HRC 60 - 65 HRC TPYUP-HHPOUON ap x ae 0.03D x 0.4D 0.03D x 0.3D 0.02D x 0.3D 0.02D x 0.3D Vc (m/min) 110-150 90-130 60-100 50-70 D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) SIDE MILLING 2 20700 0.033 2710 17520 0.029 2070 12740 0.026 1335 9550 0.023 875 3 13800 0.050 2730 11680 0.045 2080 8490 0.040 1345 6370 0.035 885 TAYLPHHOON 4 10350 0.068 2790 8760 0.061 2130 6370 0.054 1375 4780 0.047 905 5 8280 0.086 2830 7010 0.077 2160 5100 0.068 1395 3820 0.060 915 6 6900 0.104 2860 5840 0.093 2180 4250 0.083 1410 3180 0.072 920 8 5180 0.122 2520 4380 0.109 1920 3180 0.097 1235 2390 0.085 815 THYRPCHOON 10 4140 0.140 2310 3500 0.126 1760 2550 0.112 1140 1910 0.098 745 12 3450 0.158 2170 2920 0.142 1660 2120 0.126 1070 1590 0.110 700 ap x ae D2 - D3 0.02D x 0.3D 0.02D x 0.25D 0.01D x 0.02D 0.01D x 0.02D TSUYPHHMOIONIN THYLPHOON C-SD-TA LFTA SUTA HDSRSIL-LHSSS/CO G2 MDTA HF VH/UP MEF ALU MEX UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 611

Общий каталог Osawa 2021

Общий каталог Osawa 2021