Общий каталог Osawa 2018 - страница 538

Навигация

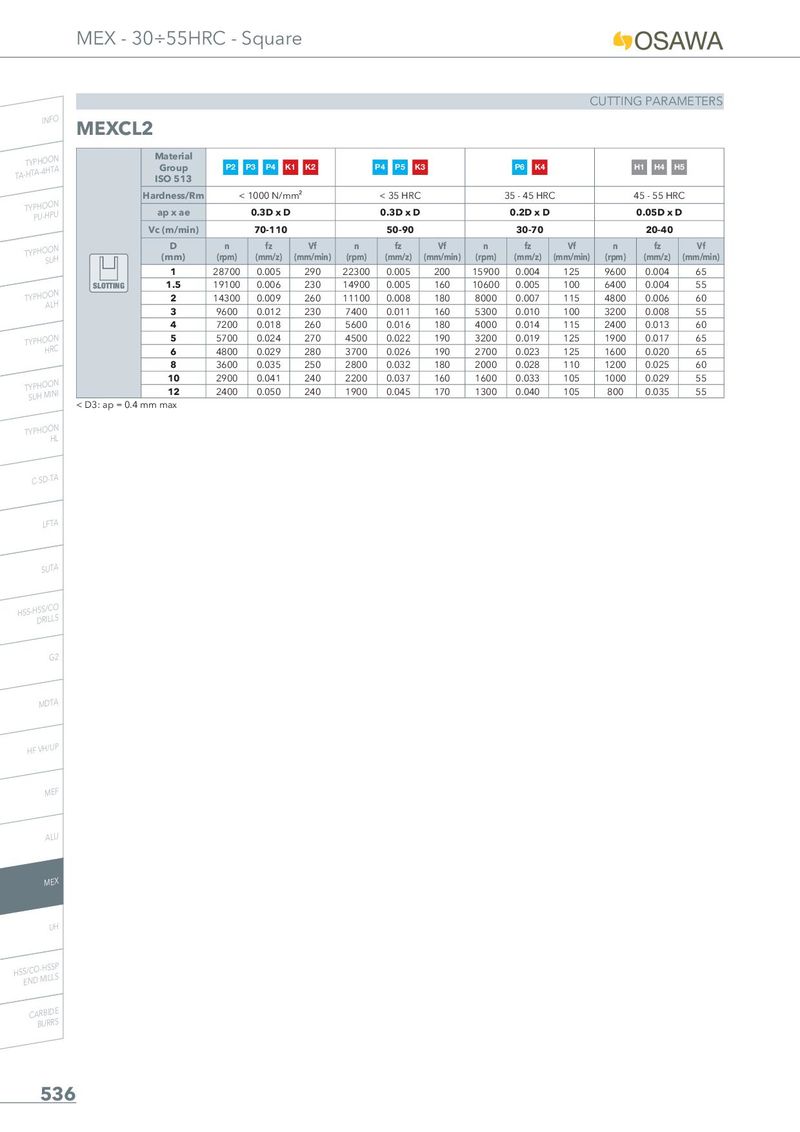

MEX - 30÷55HRC - Square CUTTING PARAMETERS INFO MEXCL2 TA-THYTPAH-4OHOTNA Material Group P2 P3 P4 K1 K2 P4 P5 K3 P6 K4 H1 H4 H5 ISO 513 Hardness/Rm < 1000 N/mm² < 35 HRC 35 - 45 HRC 45 - 55 HRC TYPPHUO-HOPNU ap x ae 0.3D x D 0.3D x D 0.2D x D 0.05D x D Vc (m/min) 70-110 50-90 30-70 20-40 TYPHOSOUNH D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 1 28700 0.005 290 22300 0.005 200 15900 0.004 125 9600 0.004 65 SLOTTING 1.5 19100 0.006 230 14900 0.005 160 10600 0.005 100 6400 0.004 55 TYPHOAOLNH 2 14300 0.009 260 11100 0.008 180 8000 0.007 115 4800 0.006 60 3 9600 0.012 230 7400 0.011 160 5300 0.010 100 3200 0.008 55 4 7200 0.018 260 5600 0.016 180 4000 0.014 115 2400 0.013 60 TYPHOHORNC 5 5700 0.024 270 4500 0.022 190 3200 0.019 125 1900 0.017 65 6 4800 0.029 280 3700 0.026 190 2700 0.023 125 1600 0.020 65 8 3600 0.035 250 2800 0.032 180 2000 0.028 110 1200 0.025 60 TSYUPHHOMOINNI 10 2900 0.041 240 2200 0.037 160 1600 0.033 105 1000 0.029 55 12 2400 0.050 240 1900 0.045 170 1300 0.040 105 800 0.035 55 < D3: ap = 0.4 mm max TYPHOOHNL C-SD-TA LFTA SUTA HSS-HDSSR/ILCLOS G2 MDTA HF VH/UP MEF ALU MEX UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS 536

Общий каталог Osawa 2021

Общий каталог Osawa 2021