Общий каталог Osawa 2018 - страница 508

Навигация

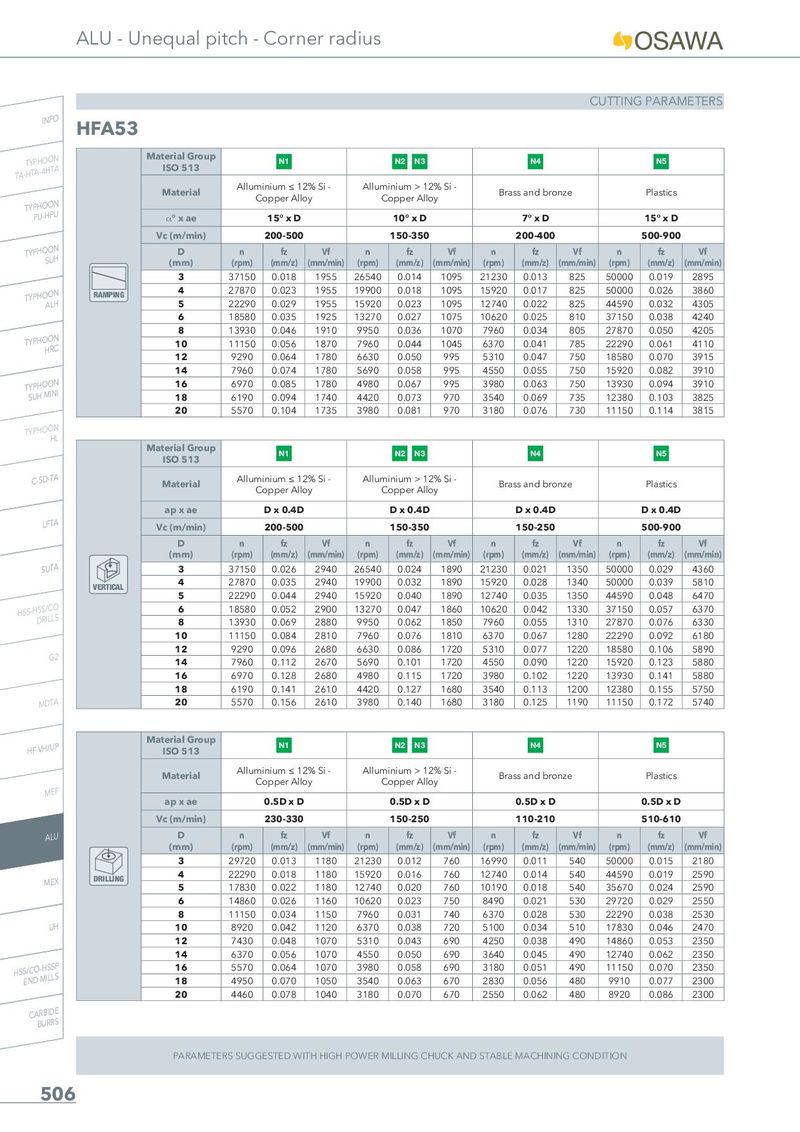

ALU - Unequal pitch - Corner radius CUTTING PARAMETERS INFO HFA53 TA-THYTPAH-4OHOTNA Material Group N1 N2 N3 N4 N5 ISO 513 Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics TYPPHUO-HOPNU Copper Alloy Copper Alloy _° x ae 15° x D 10° x D 7° x D 15° x D Vc (m/min) 200-500 150-350 200-400 500-900 TYPHOSOUNH D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 3 37150 0.018 1955 26540 0.014 1095 21230 0.013 825 50000 0.019 2895 TYPHOAOLNH RAMPING 4 27870 0.023 1955 19900 0.018 1095 15920 0.017 825 50000 0.026 3860 5 22290 0.029 1955 15920 0.023 1095 12740 0.022 825 44590 0.032 4305 6 18580 0.035 1925 13270 0.027 1075 10620 0.025 810 37150 0.038 4240 TYPHOHORNC 8 13930 0.046 1910 9950 0.036 1070 7960 0.034 805 27870 0.050 4205 10 11150 0.056 1870 7960 0.044 1045 6370 0.041 785 22290 0.061 4110 12 9290 0.064 1780 6630 0.050 995 5310 0.047 750 18580 0.070 3915 14 7960 0.074 1780 5690 0.058 995 4550 0.055 750 15920 0.082 3910 TSYUPHHOMOINNI 16 6970 0.085 1780 4980 0.067 995 3980 0.063 750 13930 0.094 3910 18 6190 0.094 1740 4420 0.073 970 3540 0.069 735 12380 0.103 3825 20 5570 0.104 1735 3980 0.081 970 3180 0.076 730 11150 0.114 3815 TYPHOOHNL Material Group N1 N2 N3 N4 N5 ISO 513 C-SD-TA Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics Copper Alloy Copper Alloy ap x ae D x 0.4D D x 0.4D D x 0.4D D x 0.4D LFTA Vc (m/min) 200-500 150-350 150-250 500-900 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) SUTA 3 37150 0.026 2940 26540 0.024 1890 21230 0.021 1350 50000 0.029 4360 VERTICAL 4 27870 0.035 2940 19900 0.032 1890 15920 0.028 1340 50000 0.039 5810 5 22290 0.044 2940 15920 0.040 1890 12740 0.035 1350 44590 0.048 6470 HSS-HDSSR/ILCLOS 6 18580 0.052 2900 13270 0.047 1860 10620 0.042 1330 37150 0.057 6370 8 13930 0.069 2880 9950 0.062 1850 7960 0.055 1310 27870 0.076 6330 10 11150 0.084 2810 7960 0.076 1810 6370 0.067 1280 22290 0.092 6180 G2 12 9290 0.096 2680 6630 0.086 1720 5310 0.077 1220 18580 0.106 5890 14 7960 0.112 2670 5690 0.101 1720 4550 0.090 1220 15920 0.123 5880 16 6970 0.128 2680 4980 0.115 1720 3980 0.102 1220 13930 0.141 5880 18 6190 0.141 2610 4420 0.127 1680 3540 0.113 1200 12380 0.155 5750 MDTA 20 5570 0.156 2610 3980 0.140 1680 3180 0.125 1190 11150 0.172 5740 HF VH/UP Material Group N1 N2 N3 N4 N5 ISO 513 Material Alluminium ≤ 12% Si - Alluminium > 12% Si - Brass and bronze Plastics Copper Alloy Copper Alloy MEF ap x ae 0.5D x D 0.5D x D 0.5D x D 0.5D x D Vc (m/min) 230-330 150-250 110-210 510-610 ALU D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 3 29720 0.013 1180 21230 0.012 760 16990 0.011 540 50000 0.015 2180 MEX DRILLING 4 22290 0.018 1180 15920 0.016 760 12740 0.014 540 44590 0.019 2590 5 17830 0.022 1180 12740 0.020 760 10190 0.018 540 35670 0.024 2590 6 14860 0.026 1160 10620 0.023 750 8490 0.021 530 29720 0.029 2550 8 11150 0.034 1150 7960 0.031 740 6370 0.028 530 22290 0.038 2530 UH 10 8920 0.042 1120 6370 0.038 720 5100 0.034 510 17830 0.046 2470 12 7430 0.048 1070 5310 0.043 690 4250 0.038 490 14860 0.053 2350 14 6370 0.056 1070 4550 0.050 690 3640 0.045 490 12740 0.062 2350 HSSE/NCDO-MHISLSLPS 16 5570 0.064 1070 3980 0.058 690 3180 0.051 490 11150 0.070 2350 18 4950 0.070 1050 3540 0.063 670 2830 0.056 480 9910 0.077 2300 20 4460 0.078 1040 3180 0.070 670 2550 0.062 480 8920 0.086 2300 CARBIDE BURRS PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION 506

Общий каталог Osawa 2021

Общий каталог Osawa 2021