Общий каталог Osawa 2018 - страница 487

Навигация

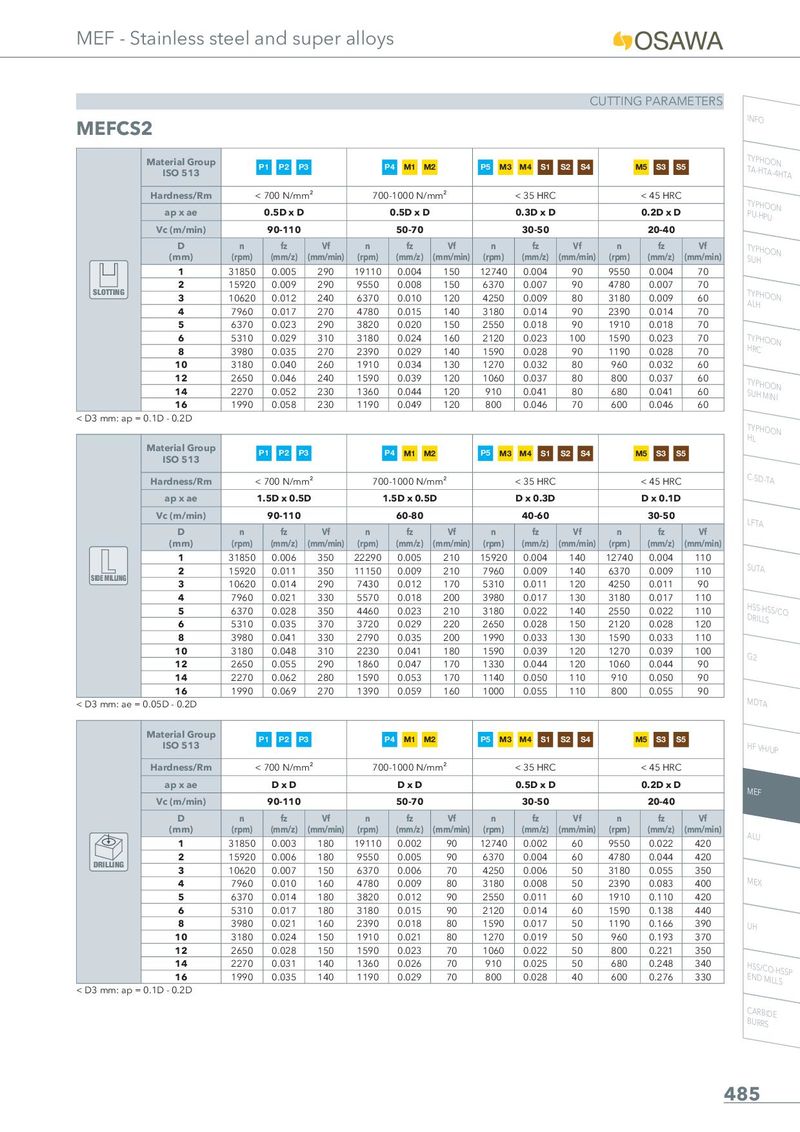

MEF - Stainless steel and super alloys CUTTING PARAMETERS MEFCS2 INFO Material Group P1 P2 P3 P4 M1 M2 P5 M3 M4 S1 S2 S4 M5 S3 S5 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 35 HRC < 45 HRC TPYUP-HHPOUON ap x ae 0.5D x D 0.5D x D 0.3D x D 0.2D x D Vc (m/min) 90-110 50-70 30-50 20-40 D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 1 31850 0.005 290 19110 0.004 150 12740 0.004 90 9550 0.004 70 SLOTTING 2 15920 0.009 290 9550 0.008 150 6370 0.007 90 4780 0.007 70 TAYLPHHOON 3 10620 0.012 240 6370 0.010 120 4250 0.009 80 3180 0.009 60 4 7960 0.017 270 4780 0.015 140 3180 0.014 90 2390 0.014 70 5 6370 0.023 290 3820 0.020 150 2550 0.018 90 1910 0.018 70 6 5310 0.029 310 3180 0.024 160 2120 0.023 100 1590 0.023 70 THYRPCHOON 8 3980 0.035 270 2390 0.029 140 1590 0.028 90 1190 0.028 70 10 3180 0.040 260 1910 0.034 130 1270 0.032 80 960 0.032 60 12 2650 0.046 240 1590 0.039 120 1060 0.037 80 800 0.037 60 TSUYPHHMOIONIN 14 2270 0.052 230 1360 0.044 120 910 0.041 80 680 0.041 60 16 1990 0.058 230 1190 0.049 120 800 0.046 70 600 0.046 60 < D3 mm: ap = 0.1D - 0.2D THYLPHOON Material Group P1 P2 P3 P4 M1 M2 P5 M3 M4 S1 S2 S4 M5 S3 S5 ISO 513 Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 35 HRC < 45 HRC C-SD-TA ap x ae 1.5D x 0.5D 1.5D x 0.5D D x 0.3D D x 0.1D Vc (m/min) 90-110 60-80 40-60 30-50 LFTA D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 1 31850 0.006 350 22290 0.005 210 15920 0.004 140 12740 0.004 110 2 15920 0.011 350 11150 0.009 210 7960 0.009 140 6370 0.009 110 SUTA SIDE MILLING 3 10620 0.014 290 7430 0.012 170 5310 0.011 120 4250 0.011 90 4 7960 0.021 330 5570 0.018 200 3980 0.017 130 3180 0.017 110 5 6370 0.028 350 4460 0.023 210 3180 0.022 140 2550 0.022 110 HDSRSIL-LHSSS/CO 6 5310 0.035 370 3720 0.029 220 2650 0.028 150 2120 0.028 120 8 3980 0.041 330 2790 0.035 200 1990 0.033 130 1590 0.033 110 10 3180 0.048 310 2230 0.041 180 1590 0.039 120 1270 0.039 100 G2 12 2650 0.055 290 1860 0.047 170 1330 0.044 120 1060 0.044 90 14 2270 0.062 280 1590 0.053 170 1140 0.050 110 910 0.050 90 16 1990 0.069 270 1390 0.059 160 1000 0.055 110 800 0.055 90 < D3 mm: ae = 0.05D - 0.2D MDTA Material Group P1 P2 P3 P4 M1 M2 P5 M3 M4 S1 S2 S4 M5 S3 S5 ISO 513 HF VH/UP Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 35 HRC < 45 HRC ap x ae DxD DxD 0.5D x D 0.2D x D MEF Vc (m/min) 90-110 50-70 30-50 20-40 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) ALU 1 31850 0.003 180 19110 0.002 90 12740 0.002 60 9550 0.022 420 DRILLING 2 15920 0.006 180 9550 0.005 90 6370 0.004 60 4780 0.044 420 3 10620 0.007 150 6370 0.006 70 4250 0.006 50 3180 0.055 350 4 7960 0.010 160 4780 0.009 80 3180 0.008 50 2390 0.083 400 MEX 5 6370 0.014 180 3820 0.012 90 2550 0.011 60 1910 0.110 420 6 5310 0.017 180 3180 0.015 90 2120 0.014 60 1590 0.138 440 8 3980 0.021 160 2390 0.018 80 1590 0.017 50 1190 0.166 390 UH 10 3180 0.024 150 1910 0.021 80 1270 0.019 50 960 0.193 370 12 2650 0.028 150 1590 0.023 70 1060 0.022 50 800 0.221 350 14 2270 0.031 140 1360 0.026 70 910 0.025 50 680 0.248 340 HENSSD/CMOIL-LHSSSP 16 1990 0.035 140 1190 0.029 70 800 0.028 40 600 0.276 330 < D3 mm: ap = 0.1D - 0.2D CBUARRRBSIDE 485

Общий каталог Osawa 2021

Общий каталог Osawa 2021