Общий каталог Osawa 2018 - страница 453

Навигация

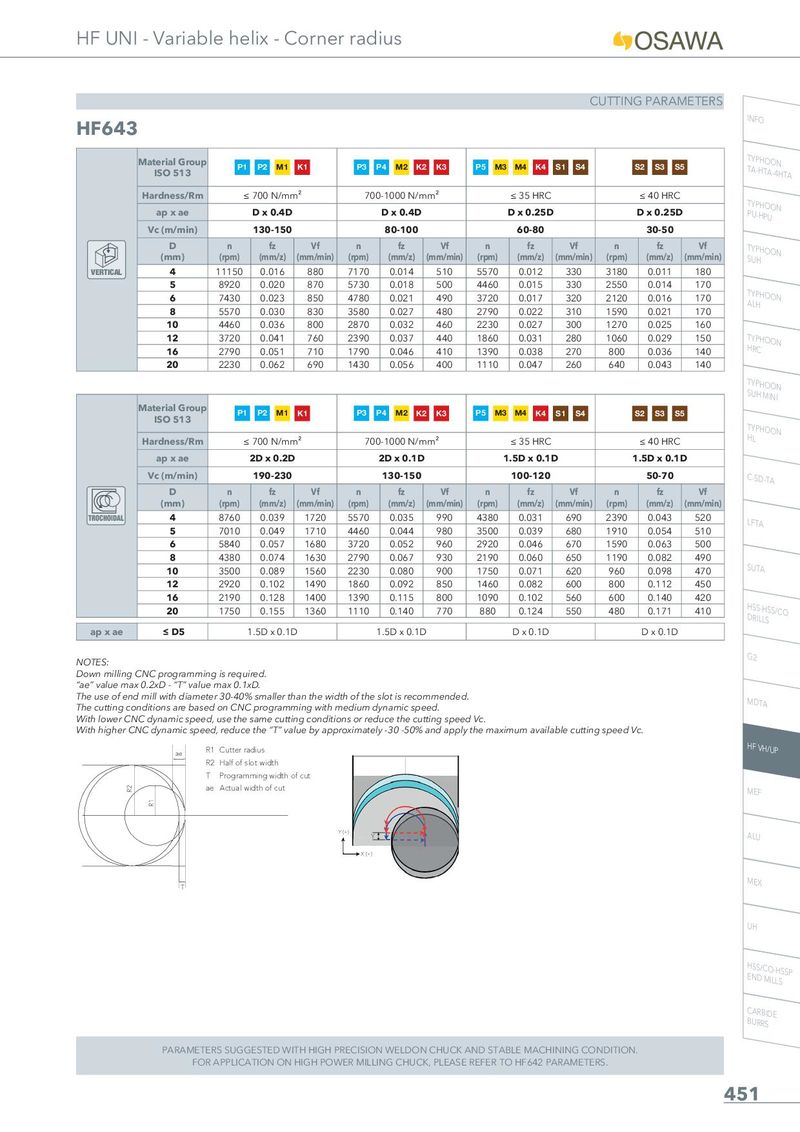

HF UNI - Variable helix - Corner radius CUTTING PARAMETERS HF643 INFO Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC TPYUP-HHPOUON ap x ae D x 0.4D D x 0.4D D x 0.25D D x 0.25D Vc (m/min) 130-150 80-100 60-80 30-50 D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) VERTICAL 4 11150 0.016 880 7170 0.014 510 5570 0.012 330 3180 0.011 180 5 8920 0.020 870 5730 0.018 500 4460 0.015 330 2550 0.014 170 TAYLPHHOON 6 7430 0.023 850 4780 0.021 490 3720 0.017 320 2120 0.016 170 8 5570 0.030 830 3580 0.027 480 2790 0.022 310 1590 0.021 170 10 4460 0.036 800 2870 0.032 460 2230 0.027 300 1270 0.025 160 12 3720 0.041 760 2390 0.037 440 1860 0.031 280 1060 0.029 150 THYRPCHOON 16 2790 0.051 710 1790 0.046 410 1390 0.038 270 800 0.036 140 20 2230 0.062 690 1430 0.056 400 1110 0.047 260 640 0.043 140 TSUYPHHMOIONIN Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 THYLPHOON Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC ap x ae 2D x 0.2D 2D x 0.1D 1.5D x 0.1D 1.5D x 0.1D Vc (m/min) 190-230 130-150 100-120 50-70 C-SD-TA D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) TROCHOIDAL 4 8760 0.039 1720 5570 0.035 990 4380 0.031 690 2390 0.043 520 LFTA 5 7010 0.049 1710 4460 0.044 980 3500 0.039 680 1910 0.054 510 6 5840 0.057 1680 3720 0.052 960 2920 0.046 670 1590 0.063 500 8 4380 0.074 1630 2790 0.067 930 2190 0.060 650 1190 0.082 490 10 3500 0.089 1560 2230 0.080 900 1750 0.071 620 960 0.098 470 SUTA 12 2920 0.102 1490 1860 0.092 850 1460 0.082 600 800 0.112 450 16 2190 0.128 1400 1390 0.115 800 1090 0.102 560 600 0.140 420 20 1750 0.155 1360 1110 0.140 770 880 0.124 550 480 0.171 410 HDSRSIL-LHSSS/CO ap x ae ≤ D5 1.5D x 0.1D 1.5D x 0.1D D x 0.1D D x 0.1D NOTES: G2 Down milling CNC programming is required. “ae” value max 0.2xD - “T” value max 0.1xD. The use of end mill with diameter 30-40% smaller than the width of the slot is recommended. MDTA The cutting conditions are based on CNC programming with medium dynamic speed. With lower CNC dynamic speed, use the same cutting conditions or reduce the cutting speed Vc. With higher CNC dynamic speed, reduce the “T” value by approximately -30 -50% and apply the maximum available cutting speed Vc. ae R1 Cutter radius HF VH/UP R2 Half of slot width T Programming width of cut R2 ae Actual width of cut MEF R1 Y (+) Y ALU X (+) T MEX UH HENSSD/CMOIL-LHSSSP CBUARRRBSIDE PARAMETERS SUGGESTED WITH HIGH PRECISION WELDON CHUCK AND STABLE MACHINING CONDITION. FOR APPLICATION ON HIGH POWER MILLING CHUCK, PLEASE REFER TO HF642 PARAMETERS. 451

Общий каталог Osawa 2021

Общий каталог Osawa 2021