Общий каталог Osawa 2018 - страница 439

Навигация

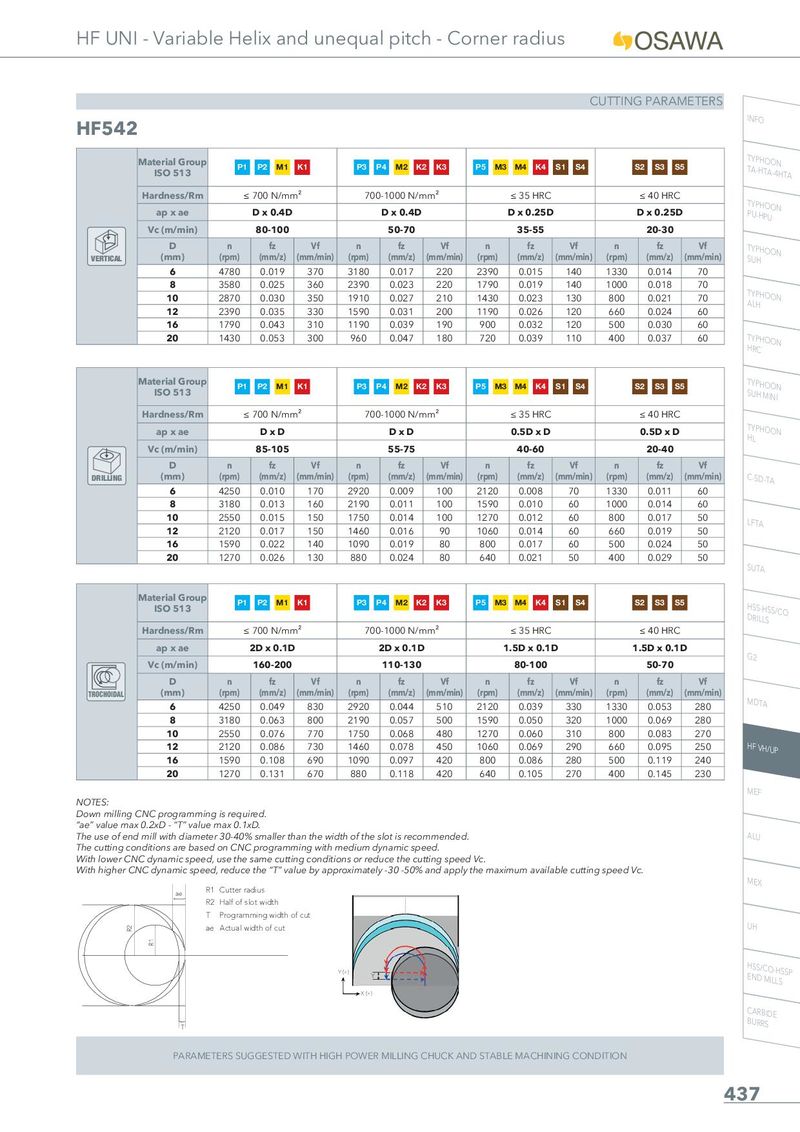

HF UNI - Variable Helix and unequal pitch - Corner radius CUTTING PARAMETERS HF542 INFO Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC TPYUP-HHPOUON ap x ae D x 0.4D D x 0.4D D x 0.25D D x 0.25D Vc (m/min) 80-100 50-70 35-55 20-30 D n fz Vf n fz Vf n fz Vf n fz Vf TSUYPHHOON VERTICAL (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 6 4780 0.019 370 3180 0.017 220 2390 0.015 140 1330 0.014 70 8 3580 0.025 360 2390 0.023 220 1790 0.019 140 1000 0.018 70 TAYLPHHOON 10 2870 0.030 350 1910 0.027 210 1430 0.023 130 800 0.021 70 12 2390 0.035 330 1590 0.031 200 1190 0.026 120 660 0.024 60 16 1790 0.043 310 1190 0.039 190 900 0.032 120 500 0.030 60 20 1430 0.053 300 960 0.047 180 720 0.039 110 400 0.037 60 THYRPCHOON Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 TSUYPHHMOIONIN ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC ap x ae DxD DxD 0.5D x D 0.5D x D THYLPHOON Vc (m/min) 85-105 55-75 40-60 20-40 D n fz Vf n fz Vf n fz Vf n fz Vf DRILLING (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) C-SD-TA 6 4250 0.010 170 2920 0.009 100 2120 0.008 70 1330 0.011 60 8 3180 0.013 160 2190 0.011 100 1590 0.010 60 1000 0.014 60 10 2550 0.015 150 1750 0.014 100 1270 0.012 60 800 0.017 50 LFTA 12 2120 0.017 150 1460 0.016 90 1060 0.014 60 660 0.019 50 16 1590 0.022 140 1090 0.019 80 800 0.017 60 500 0.024 50 20 1270 0.026 130 880 0.024 80 640 0.021 50 400 0.029 50 SUTA Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 HDSRSIL-LHSSS/CO Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC ap x ae 2D x 0.1D 2D x 0.1D 1.5D x 0.1D 1.5D x 0.1D Vc (m/min) 160-200 110-130 80-100 50-70 G2 D n fz Vf n fz Vf n fz Vf n fz Vf TROCHOIDAL (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 6 4250 0.049 830 2920 0.044 510 2120 0.039 330 1330 0.053 280 MDTA 8 3180 0.063 800 2190 0.057 500 1590 0.050 320 1000 0.069 280 10 2550 0.076 770 1750 0.068 480 1270 0.060 310 800 0.083 270 12 2120 0.086 730 1460 0.078 450 1060 0.069 290 660 0.095 250 HF VH/UP 16 1590 0.108 690 1090 0.097 420 800 0.086 280 500 0.119 240 20 1270 0.131 670 880 0.118 420 640 0.105 270 400 0.145 230 MEF NOTES: Down milling CNC programming is required. “ae” value max 0.2xD - “T” value max 0.1xD. The use of end mill with diameter 30-40% smaller than the width of the slot is recommended. ALU The cutting conditions are based on CNC programming with medium dynamic speed. With lower CNC dynamic speed, use the same cutting conditions or reduce the cutting speed Vc. With higher CNC dynamic speed, reduce the “T” value by approximately -30 -50% and apply the maximum available cutting speed Vc. R1 Cutter radius MEX ae R2 Half of slot width T Programming width of cut R2 ae Actual width of cut UH R1 Y (+) Y HENSSD/CMOIL-LHSSSP X (+) T CBUARRRBSIDE PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION 437

Общий каталог Osawa 2021

Общий каталог Osawa 2021