Общий каталог Osawa 2018 - страница 418

Навигация

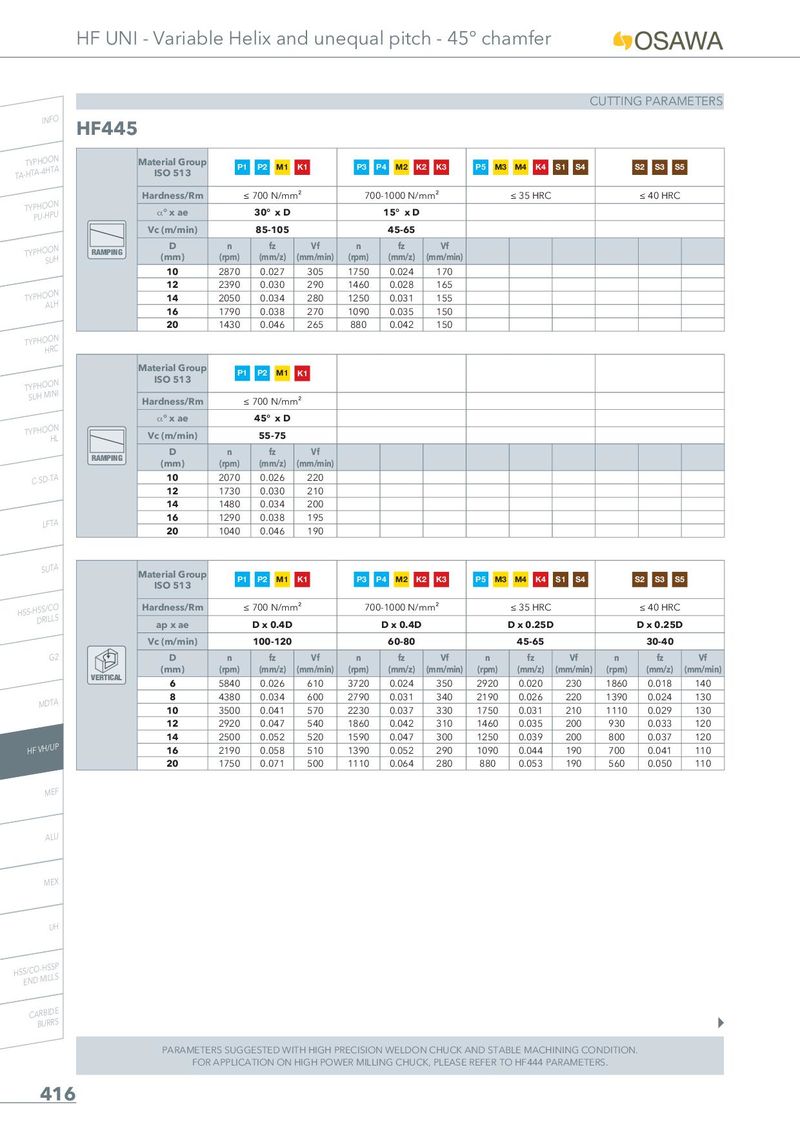

HF UNI - Variable Helix and unequal pitch - 45° chamfer CUTTING PARAMETERS INFO HF445 TA-THYTPAH-4OHOTNA Material Group P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 ISO 513 Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC TYPPHUO-HOPNU _° x ae 30° x D 15° x D Vc (m/min) 85-105 45-65 TYPHOSOUNH RAMPING D n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) 10 2870 0.027 305 1750 0.024 170 12 2390 0.030 290 1460 0.028 165 TYPHOAOLNH 14 2050 0.034 280 1250 0.031 155 16 1790 0.038 270 1090 0.035 150 20 1430 0.046 265 880 0.042 150 TYPHOHORNC Material Group P1 P2 M1 K1 TSYUPHHOMOINNI ISO 513 Hardness/Rm ≤ 700 N/mm² _° x ae 45° x D TYPHOOHNL Vc (m/min) 55-75 RAMPING D n fz Vf (mm) (rpm) (mm/z) (mm/min) C-SD-TA 10 2070 0.026 220 12 1730 0.030 210 14 1480 0.034 200 LFTA 16 1290 0.038 195 20 1040 0.046 190 SUTA Material Group ISO 513 P1 P2 M1 K1 P3 P4 M2 K2 K3 P5 M3 M4 K4 S1 S4 S2 S3 S5 HSS-HDSSR/ILCLOS Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC ap x ae D x 0.4D D x 0.4D D x 0.25D D x 0.25D Vc (m/min) 100-120 60-80 45-65 30-40 G2 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) VERTICAL 6 5840 0.026 610 3720 0.024 350 2920 0.020 230 1860 0.018 140 MDTA 8 4380 0.034 600 2790 0.031 340 2190 0.026 220 1390 0.024 130 10 3500 0.041 570 2230 0.037 330 1750 0.031 210 1110 0.029 130 12 2920 0.047 540 1860 0.042 310 1460 0.035 200 930 0.033 120 14 2500 0.052 520 1590 0.047 300 1250 0.039 200 800 0.037 120 HF VH/UP 16 2190 0.058 510 1390 0.052 290 1090 0.044 190 700 0.041 110 20 1750 0.071 500 1110 0.064 280 880 0.053 190 560 0.050 110 MEF ALU MEX UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS PARAMETERS SUGGESTED WITH HIGH PRECISION WELDON CHUCK AND STABLE MACHINING CONDITION. FOR APPLICATION ON HIGH POWER MILLING CHUCK, PLEASE REFER TO HF444 PARAMETERS. 416

Общий каталог Osawa 2021

Общий каталог Osawa 2021