Общий каталог Osawa 2018 - страница 336

Навигация

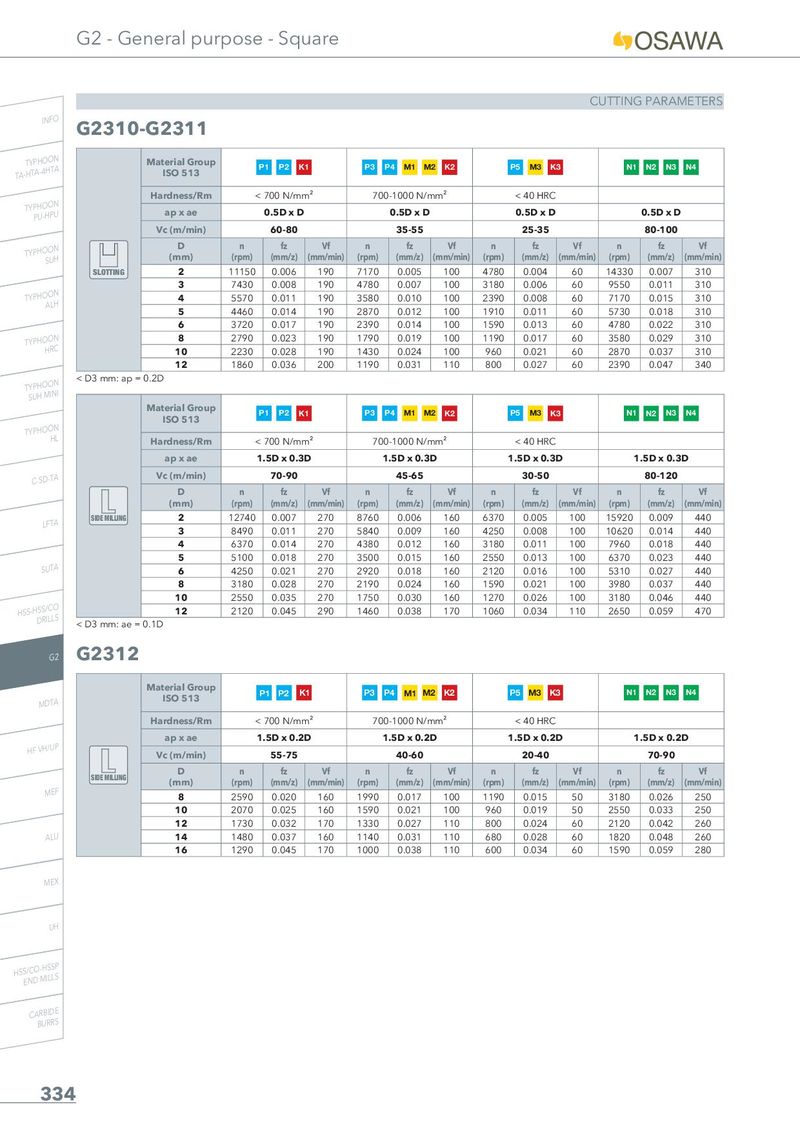

G2 - General purpose - Square CUTTING PARAMETERS INFO G2310-G2311 TA-THYTPAH-4OHOTNA Material Group P1 P2 K1 P3 P4 M1 M2 K2 P5 M3 K3 N1 N2 N3 N4 ISO 513 Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 40 HRC TYPPHUO-HOPNU ap x ae 0.5D x D 0.5D x D 0.5D x D 0.5D x D Vc (m/min) 60-80 35-55 25-35 80-100 TYPHOSOUNH D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) SLOTTING 2 11150 0.006 190 7170 0.005 100 4780 0.004 60 14330 0.007 310 3 7430 0.008 190 4780 0.007 100 3180 0.006 60 9550 0.011 310 TYPHOAOLNH 4 5570 0.011 190 3580 0.010 100 2390 0.008 60 7170 0.015 310 5 4460 0.014 190 2870 0.012 100 1910 0.011 60 5730 0.018 310 6 3720 0.017 190 2390 0.014 100 1590 0.013 60 4780 0.022 310 TYPHOHORNC 8 2790 0.023 190 1790 0.019 100 1190 0.017 60 3580 0.029 310 10 2230 0.028 190 1430 0.024 100 960 0.021 60 2870 0.037 310 12 1860 0.036 200 1190 0.031 110 800 0.027 60 2390 0.047 340 TSYUPHHOMOINNI < D3 mm: ap = 0.2D Material Group P1 P2 K1 P3 P4 M1 M2 K2 P5 M3 K3 N1 N2 N3 N4 ISO 513 TYPHOOHNL Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 40 HRC ap x ae 1.5D x 0.3D 1.5D x 0.3D 1.5D x 0.3D 1.5D x 0.3D C-SD-TA Vc (m/min) 70-90 45-65 30-50 80-120 D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) LFTA SIDE MILLING 2 12740 0.007 270 8760 0.006 160 6370 0.005 100 15920 0.009 440 3 8490 0.011 270 5840 0.009 160 4250 0.008 100 10620 0.014 440 4 6370 0.014 270 4380 0.012 160 3180 0.011 100 7960 0.018 440 5 5100 0.018 270 3500 0.015 160 2550 0.013 100 6370 0.023 440 SUTA 6 4250 0.021 270 2920 0.018 160 2120 0.016 100 5310 0.027 440 8 3180 0.028 270 2190 0.024 160 1590 0.021 100 3980 0.037 440 10 2550 0.035 270 1750 0.030 160 1270 0.026 100 3180 0.046 440 HSS-HDSSR/ILCLOS 12 2120 0.045 290 1460 0.038 170 1060 0.034 110 2650 0.059 470 < D3 mm: ae = 0.1D G2 G2312 Material Group P1 P2 K1 P3 P4 M1 M2 K2 P5 M3 K3 N1 N2 N3 N4 MDTA ISO 513 Hardness/Rm < 700 N/mm² 700-1000 N/mm² < 40 HRC ap x ae 1.5D x 0.2D 1.5D x 0.2D 1.5D x 0.2D 1.5D x 0.2D HF VH/UP Vc (m/min) 55-75 40-60 20-40 70-90 SIDE MILLING D n fz Vf n fz Vf n fz Vf n fz Vf (mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) MEF 8 2590 0.020 160 1990 0.017 100 1190 0.015 50 3180 0.026 250 10 2070 0.025 160 1590 0.021 100 960 0.019 50 2550 0.033 250 12 1730 0.032 170 1330 0.027 110 800 0.024 60 2120 0.042 260 ALU 14 1480 0.037 160 1140 0.031 110 680 0.028 60 1820 0.048 260 16 1290 0.045 170 1000 0.038 110 600 0.034 60 1590 0.059 280 MEX UH HSSE/NCDO-MHISLSLPS CARBIDE BURRS 334

Общий каталог Osawa 2021

Общий каталог Osawa 2021