Общий каталог Osawa 2018 - страница 163

Навигация

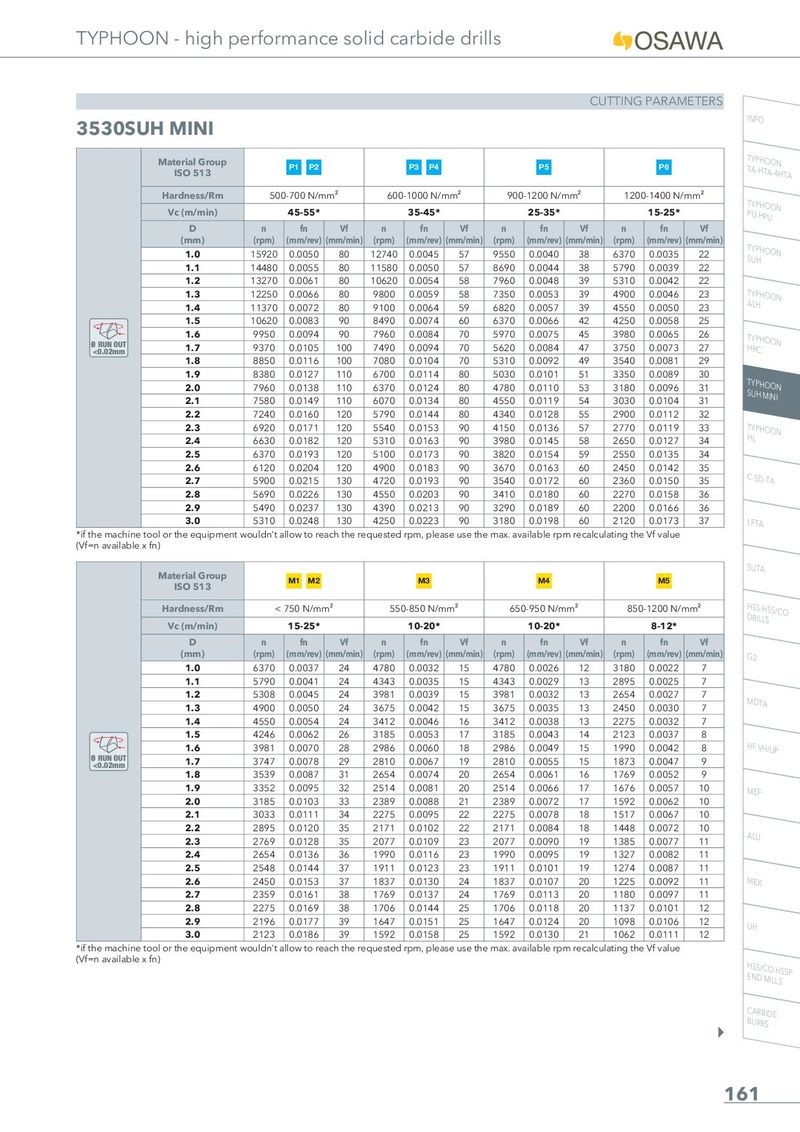

TYPHOON - high performance solid carbide drills CUTTING PARAMETERS 3530SUH MINI INFO Material Group P1 P2 P3 P4 P5 P6 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm 500-700 N/mm² 600-1000 N/mm² 900-1200 N/mm² 1200-1400 N/mm² TPYUP-HHPOUON Vc (m/min) 45-55* 35-45* 25-35* 15-25* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) TSUYPHHOON 1.0 15920 0.0050 80 12740 0.0045 57 9550 0.0040 38 6370 0.0035 22 1.1 14480 0.0055 80 11580 0.0050 57 8690 0.0044 38 5790 0.0039 22 1.2 13270 0.0061 80 10620 0.0054 58 7960 0.0048 39 5310 0.0042 22 1.3 12250 0.0066 80 9800 0.0059 58 7350 0.0053 39 4900 0.0046 23 TAYLPHHOON 1.4 11370 0.0072 80 9100 0.0064 59 6820 0.0057 39 4550 0.0050 23 1.5 10620 0.0083 90 8490 0.0074 60 6370 0.0066 42 4250 0.0058 25 1.6 9950 0.0094 90 7960 0.0084 70 5970 0.0075 45 3980 0.0065 26 THYRPCHOON Ø RUN OUT 1.7 9370 0.0105 100 7490 0.0094 70 5620 0.0084 47 3750 0.0073 27 <0.02mm 1.8 8850 0.0116 100 7080 0.0104 70 5310 0.0092 49 3540 0.0081 29 1.9 8380 0.0127 110 6700 0.0114 80 5030 0.0101 51 3350 0.0089 30 TSUYPHHMOIONIN 2.0 7960 0.0138 110 6370 0.0124 80 4780 0.0110 53 3180 0.0096 31 2.1 7580 0.0149 110 6070 0.0134 80 4550 0.0119 54 3030 0.0104 31 2.2 7240 0.0160 120 5790 0.0144 80 4340 0.0128 55 2900 0.0112 32 2.3 6920 0.0171 120 5540 0.0153 90 4150 0.0136 57 2770 0.0119 33 THYLPHOON 2.4 6630 0.0182 120 5310 0.0163 90 3980 0.0145 58 2650 0.0127 34 2.5 6370 0.0193 120 5100 0.0173 90 3820 0.0154 59 2550 0.0135 34 2.6 6120 0.0204 120 4900 0.0183 90 3670 0.0163 60 2450 0.0142 35 2.7 5900 0.0215 130 4720 0.0193 90 3540 0.0172 60 2360 0.0150 35 C-SD-TA 2.8 5690 0.0226 130 4550 0.0203 90 3410 0.0180 60 2270 0.0158 36 2.9 5490 0.0237 130 4390 0.0213 90 3290 0.0189 60 2200 0.0166 36 3.0 5310 0.0248 130 4250 0.0223 90 3180 0.0198 60 2120 0.0173 37 LFTA *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) Material Group SUTA ISO 513 M1 M2 M3 M4 M5 Hardness/Rm < 750 N/mm² 550-850 N/mm² 650-950 N/mm² 850-1200 N/mm² HDSRSIL-LHSSS/CO Vc (m/min) 15-25* 10-20* 10-20* 8-12* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) G2 1.0 6370 0.0037 24 4780 0.0032 15 4780 0.0026 12 3180 0.0022 7 1.1 5790 0.0041 24 4343 0.0035 15 4343 0.0029 13 2895 0.0025 7 1.2 5308 0.0045 24 3981 0.0039 15 3981 0.0032 13 2654 0.0027 7 MDTA 1.3 4900 0.0050 24 3675 0.0042 15 3675 0.0035 13 2450 0.0030 7 1.4 4550 0.0054 24 3412 0.0046 16 3412 0.0038 13 2275 0.0032 7 1.5 4246 0.0062 26 3185 0.0053 17 3185 0.0043 14 2123 0.0037 8 1.6 3981 0.0070 28 2986 0.0060 18 2986 0.0049 15 1990 0.0042 8 HF VH/UP Ø RUN OUT 1.7 3747 0.0078 29 2810 0.0067 19 2810 0.0055 15 1873 0.0047 9 <0.02mm 1.8 3539 0.0087 31 2654 0.0074 20 2654 0.0061 16 1769 0.0052 9 1.9 3352 0.0095 32 2514 0.0081 20 2514 0.0066 17 1676 0.0057 10 MEF 2.0 3185 0.0103 33 2389 0.0088 21 2389 0.0072 17 1592 0.0062 10 2.1 3033 0.0111 34 2275 0.0095 22 2275 0.0078 18 1517 0.0067 10 2.2 2895 0.0120 35 2171 0.0102 22 2171 0.0084 18 1448 0.0072 10 ALU 2.3 2769 0.0128 35 2077 0.0109 23 2077 0.0090 19 1385 0.0077 11 2.4 2654 0.0136 36 1990 0.0116 23 1990 0.0095 19 1327 0.0082 11 2.5 2548 0.0144 37 1911 0.0123 23 1911 0.0101 19 1274 0.0087 11 2.6 2450 0.0153 37 1837 0.0130 24 1837 0.0107 20 1225 0.0092 11 MEX 2.7 2359 0.0161 38 1769 0.0137 24 1769 0.0113 20 1180 0.0097 11 2.8 2275 0.0169 38 1706 0.0144 25 1706 0.0118 20 1137 0.0101 12 2.9 2196 0.0177 39 1647 0.0151 25 1647 0.0124 20 1098 0.0106 12 UH 3.0 2123 0.0186 39 1592 0.0158 25 1592 0.0130 21 1062 0.0111 12 *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 161

Общий каталог Osawa 2021

Общий каталог Osawa 2021