Общий каталог Osawa 2018 - страница 148

Навигация

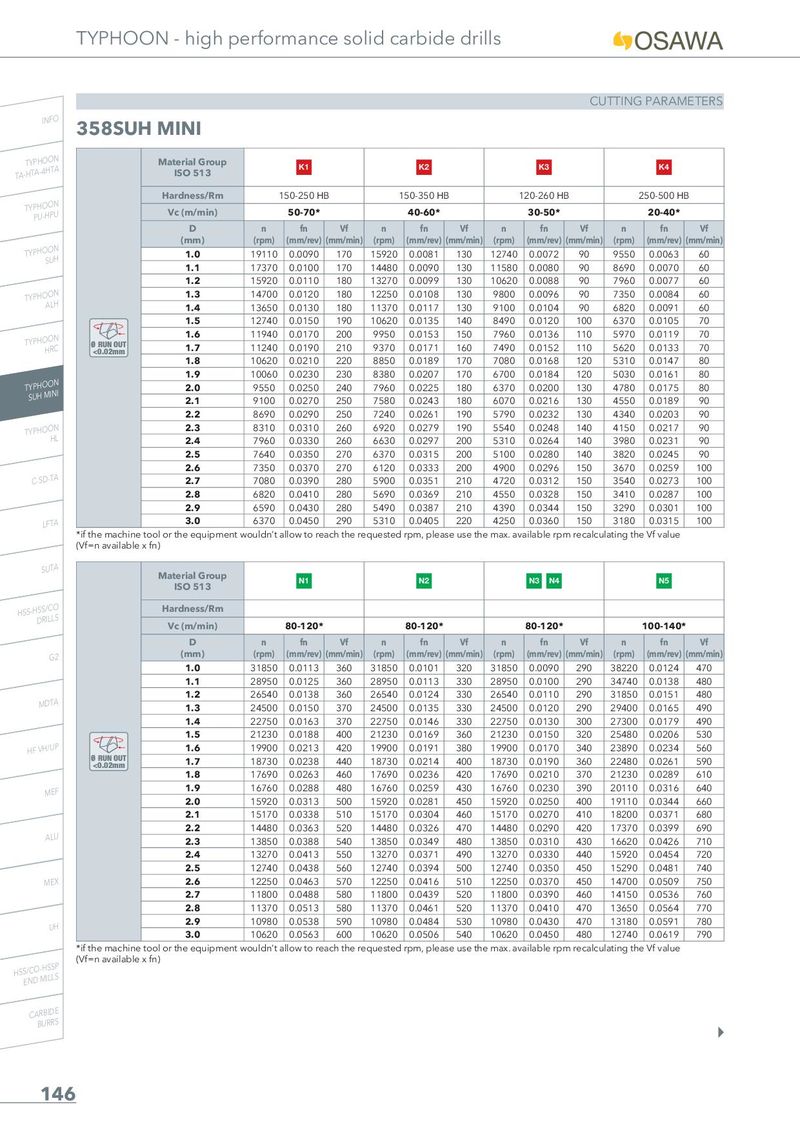

TYPHOON - high performance solid carbide drills CUTTING PARAMETERS INFO 358SUH MINI TA-THYTPAH-4OHOTNA Material Group K1 K2 K3 K4 ISO 513 Hardness/Rm 150-250 HB 150-350 HB 120-260 HB 250-500 HB TYPPHUO-HOPNU Vc (m/min) 50-70* 40-60* 30-50* 20-40* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) TYPHOSOUNH 1.0 19110 0.0090 170 15920 0.0081 130 12740 0.0072 90 9550 0.0063 60 1.1 17370 0.0100 170 14480 0.0090 130 11580 0.0080 90 8690 0.0070 60 1.2 15920 0.0110 180 13270 0.0099 130 10620 0.0088 90 7960 0.0077 60 TYPHOAOLNH 1.3 14700 0.0120 180 12250 0.0108 130 9800 0.0096 90 7350 0.0084 60 1.4 13650 0.0130 180 11370 0.0117 130 9100 0.0104 90 6820 0.0091 60 1.5 12740 0.0150 190 10620 0.0135 140 8490 0.0120 100 6370 0.0105 70 TYPHOHORNC 1.6 11940 0.0170 200 9950 0.0153 150 7960 0.0136 110 5970 0.0119 70 Ø RUN OUT 1.7 11240 0.0190 210 9370 0.0171 160 7490 0.0152 110 5620 0.0133 70 <0.02mm 1.8 10620 0.0210 220 8850 0.0189 170 7080 0.0168 120 5310 0.0147 80 1.9 10060 0.0230 230 8380 0.0207 170 6700 0.0184 120 5030 0.0161 80 TSYUPHHOMOINNI 2.0 9550 0.0250 240 7960 0.0225 180 6370 0.0200 130 4780 0.0175 80 2.1 9100 0.0270 250 7580 0.0243 180 6070 0.0216 130 4550 0.0189 90 2.2 8690 0.0290 250 7240 0.0261 190 5790 0.0232 130 4340 0.0203 90 TYPHOOHNL 2.3 8310 0.0310 260 6920 0.0279 190 5540 0.0248 140 4150 0.0217 90 2.4 7960 0.0330 260 6630 0.0297 200 5310 0.0264 140 3980 0.0231 90 2.5 7640 0.0350 270 6370 0.0315 200 5100 0.0280 140 3820 0.0245 90 2.6 7350 0.0370 270 6120 0.0333 200 4900 0.0296 150 3670 0.0259 100 C-SD-TA 2.7 7080 0.0390 280 5900 0.0351 210 4720 0.0312 150 3540 0.0273 100 2.8 6820 0.0410 280 5690 0.0369 210 4550 0.0328 150 3410 0.0287 100 2.9 6590 0.0430 280 5490 0.0387 210 4390 0.0344 150 3290 0.0301 100 LFTA 3.0 6370 0.0450 290 5310 0.0405 220 4250 0.0360 150 3180 0.0315 100 *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) SUTA Material Group ISO 513 N1 N2 N3 N4 N5 HSS-HDSSR/ILCLOS Hardness/Rm Vc (m/min) 80-120* 80-120* 80-120* 100-140* D n fn Vf n fn Vf n fn Vf n fn Vf G2 (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) 1.0 31850 0.0113 360 31850 0.0101 320 31850 0.0090 290 38220 0.0124 470 1.1 28950 0.0125 360 28950 0.0113 330 28950 0.0100 290 34740 0.0138 480 MDTA 1.2 26540 0.0138 360 26540 0.0124 330 26540 0.0110 290 31850 0.0151 480 1.3 24500 0.0150 370 24500 0.0135 330 24500 0.0120 290 29400 0.0165 490 1.4 22750 0.0163 370 22750 0.0146 330 22750 0.0130 300 27300 0.0179 490 1.5 21230 0.0188 400 21230 0.0169 360 21230 0.0150 320 25480 0.0206 530 HF VH/UP 1.6 19900 0.0213 420 19900 0.0191 380 19900 0.0170 340 23890 0.0234 560 Ø RUN OUT 1.7 18730 0.0238 440 18730 0.0214 400 18730 0.0190 360 22480 0.0261 590 <0.02mm 1.8 17690 0.0263 460 17690 0.0236 420 17690 0.0210 370 21230 0.0289 610 MEF 1.9 16760 0.0288 480 16760 0.0259 430 16760 0.0230 390 20110 0.0316 640 2.0 15920 0.0313 500 15920 0.0281 450 15920 0.0250 400 19110 0.0344 660 2.1 15170 0.0338 510 15170 0.0304 460 15170 0.0270 410 18200 0.0371 680 2.2 14480 0.0363 520 14480 0.0326 470 14480 0.0290 420 17370 0.0399 690 ALU 2.3 13850 0.0388 540 13850 0.0349 480 13850 0.0310 430 16620 0.0426 710 2.4 13270 0.0413 550 13270 0.0371 490 13270 0.0330 440 15920 0.0454 720 2.5 12740 0.0438 560 12740 0.0394 500 12740 0.0350 450 15290 0.0481 740 MEX 2.6 12250 0.0463 570 12250 0.0416 510 12250 0.0370 450 14700 0.0509 750 2.7 11800 0.0488 580 11800 0.0439 520 11800 0.0390 460 14150 0.0536 760 2.8 11370 0.0513 580 11370 0.0461 520 11370 0.0410 470 13650 0.0564 770 UH 2.9 10980 0.0538 590 10980 0.0484 530 10980 0.0430 470 13180 0.0591 780 3.0 10620 0.0563 600 10620 0.0506 540 10620 0.0450 480 12740 0.0619 790 *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value HSSE/NCDO-MHISLSLPS (Vf=n available x fn) CARBIDE BURRS 146

Общий каталог Osawa 2021

Общий каталог Osawa 2021