Общий каталог Osawa 2018 - страница 147

Навигация

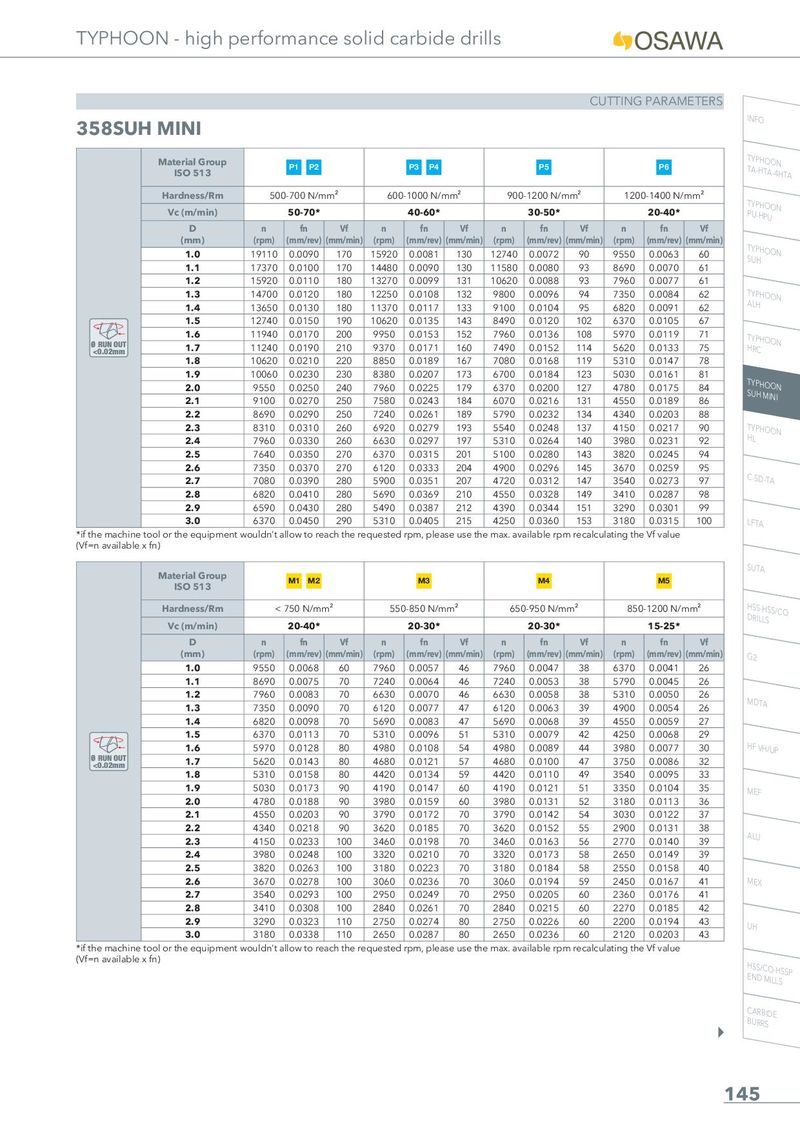

TYPHOON - high performance solid carbide drills CUTTING PARAMETERS 358SUH MINI INFO Material Group P1 P2 P3 P4 P5 P6 TTYAP-HHTOAO-4NHTA ISO 513 Hardness/Rm 500-700 N/mm² 600-1000 N/mm² 900-1200 N/mm² 1200-1400 N/mm² TPYUP-HHPOUON Vc (m/min) 50-70* 40-60* 30-50* 20-40* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) TSUYPHHOON 1.0 19110 0.0090 170 15920 0.0081 130 12740 0.0072 90 9550 0.0063 60 1.1 17370 0.0100 170 14480 0.0090 130 11580 0.0080 93 8690 0.0070 61 1.2 15920 0.0110 180 13270 0.0099 131 10620 0.0088 93 7960 0.0077 61 1.3 14700 0.0120 180 12250 0.0108 132 9800 0.0096 94 7350 0.0084 62 TAYLPHHOON 1.4 13650 0.0130 180 11370 0.0117 133 9100 0.0104 95 6820 0.0091 62 1.5 12740 0.0150 190 10620 0.0135 143 8490 0.0120 102 6370 0.0105 67 1.6 11940 0.0170 200 9950 0.0153 152 7960 0.0136 108 5970 0.0119 71 THYRPCHOON Ø RUN OUT 1.7 11240 0.0190 210 9370 0.0171 160 7490 0.0152 114 5620 0.0133 75 <0.02mm 1.8 10620 0.0210 220 8850 0.0189 167 7080 0.0168 119 5310 0.0147 78 1.9 10060 0.0230 230 8380 0.0207 173 6700 0.0184 123 5030 0.0161 81 TSUYPHHMOIONIN 2.0 9550 0.0250 240 7960 0.0225 179 6370 0.0200 127 4780 0.0175 84 2.1 9100 0.0270 250 7580 0.0243 184 6070 0.0216 131 4550 0.0189 86 2.2 8690 0.0290 250 7240 0.0261 189 5790 0.0232 134 4340 0.0203 88 2.3 8310 0.0310 260 6920 0.0279 193 5540 0.0248 137 4150 0.0217 90 THYLPHOON 2.4 7960 0.0330 260 6630 0.0297 197 5310 0.0264 140 3980 0.0231 92 2.5 7640 0.0350 270 6370 0.0315 201 5100 0.0280 143 3820 0.0245 94 2.6 7350 0.0370 270 6120 0.0333 204 4900 0.0296 145 3670 0.0259 95 2.7 7080 0.0390 280 5900 0.0351 207 4720 0.0312 147 3540 0.0273 97 C-SD-TA 2.8 6820 0.0410 280 5690 0.0369 210 4550 0.0328 149 3410 0.0287 98 2.9 6590 0.0430 280 5490 0.0387 212 4390 0.0344 151 3290 0.0301 99 3.0 6370 0.0450 290 5310 0.0405 215 4250 0.0360 153 3180 0.0315 100 LFTA *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) Material Group SUTA ISO 513 M1 M2 M3 M4 M5 Hardness/Rm < 750 N/mm² 550-850 N/mm² 650-950 N/mm² 850-1200 N/mm² HDSRSIL-LHSSS/CO Vc (m/min) 20-40* 20-30* 20-30* 15-25* D n fn Vf n fn Vf n fn Vf n fn Vf (mm) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) (rpm) (mm/rev) (mm/min) G2 1.0 9550 0.0068 60 7960 0.0057 46 7960 0.0047 38 6370 0.0041 26 1.1 8690 0.0075 70 7240 0.0064 46 7240 0.0053 38 5790 0.0045 26 1.2 7960 0.0083 70 6630 0.0070 46 6630 0.0058 38 5310 0.0050 26 MDTA 1.3 7350 0.0090 70 6120 0.0077 47 6120 0.0063 39 4900 0.0054 26 1.4 6820 0.0098 70 5690 0.0083 47 5690 0.0068 39 4550 0.0059 27 1.5 6370 0.0113 70 5310 0.0096 51 5310 0.0079 42 4250 0.0068 29 1.6 5970 0.0128 80 4980 0.0108 54 4980 0.0089 44 3980 0.0077 30 HF VH/UP Ø RUN OUT 1.7 5620 0.0143 80 4680 0.0121 57 4680 0.0100 47 3750 0.0086 32 <0.02mm 1.8 5310 0.0158 80 4420 0.0134 59 4420 0.0110 49 3540 0.0095 33 1.9 5030 0.0173 90 4190 0.0147 60 4190 0.0121 51 3350 0.0104 35 MEF 2.0 4780 0.0188 90 3980 0.0159 60 3980 0.0131 52 3180 0.0113 36 2.1 4550 0.0203 90 3790 0.0172 70 3790 0.0142 54 3030 0.0122 37 2.2 4340 0.0218 90 3620 0.0185 70 3620 0.0152 55 2900 0.0131 38 ALU 2.3 4150 0.0233 100 3460 0.0198 70 3460 0.0163 56 2770 0.0140 39 2.4 3980 0.0248 100 3320 0.0210 70 3320 0.0173 58 2650 0.0149 39 2.5 3820 0.0263 100 3180 0.0223 70 3180 0.0184 58 2550 0.0158 40 2.6 3670 0.0278 100 3060 0.0236 70 3060 0.0194 59 2450 0.0167 41 MEX 2.7 3540 0.0293 100 2950 0.0249 70 2950 0.0205 60 2360 0.0176 41 2.8 3410 0.0308 100 2840 0.0261 70 2840 0.0215 60 2270 0.0185 42 2.9 3290 0.0323 110 2750 0.0274 80 2750 0.0226 60 2200 0.0194 43 UH 3.0 3180 0.0338 110 2650 0.0287 80 2650 0.0236 60 2120 0.0203 43 *if the machine tool or the equipment wouldn’t allow to reach the requested rpm, please use the max. available rpm recalculating the Vf value (Vf=n available x fn) HENSSD/CMOIL-LHSSSP CBUARRRBSIDE 145

Общий каталог Osawa 2021

Общий каталог Osawa 2021