Общий каталог Lamina Technologies 2019 - 2020 - страница 178

Навигация

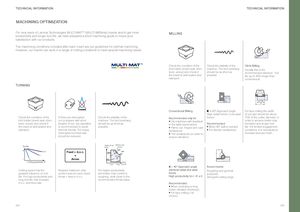

TECHNICAL INFORMATION TECHNICAL INFORMATION MACHINING OPTIMIZATION For new users of Lamina Technologies MULTI-MATTM (MULTI-MATerial) inserts and to get more MILLING productivity and longer tool life, we have prepared a short machining guide to insure your satisfaction with our products. The machining conditions included after each insert are our guidelines for optimal machining. However, our inserts can work in a range of cutting conditions to meet special machining needs. Vf Check the condition of the Check the stability of the Climb Milling tool holder (insert seat, shim, machine. The tool overhang Usually this is the lever, screw) and check if should be as short as recommended direction. Tool the insert is well seated and possible. life up to 40% longer than clamped. conventional. TURNING Fv h = fz fz 0.7 x D Vf D Coolant Conventional Milling К = 90° Approach angle For face milling the width High radial forces / Low axial of cut (ae) should be about Check the condition of the If there are interrupted Check the stability of the Recommended only for: forces. 70% of the cutter diameter, in tool holder (insert seat, shim, cut or passes with short machine. The tool overhang • Old machines with backlash order to achieve better chip lever, screw) and check if lengths of cut, dry operation should be as short as in the table transmission Recommended: formation and longer tool the insert is well seated and is recommended to avoid possible. • Flame cut, forged and cast • When 90° wall is needed life. For limited engagement clamped. thermal shocks. For heavy workpieces • For slender workpieces conditions, it is necessary to interrupted cut feed rate • Thin workpieces (in order to increase feed per tooth. should be reduced. reduce vibration) Tool life Depth of cut Section max[mm][mm2] + d.o.c. Feed x d.o.c. fn = 45° - Vc Amax fz h = 0.71 x fz - Cutting parameters + Feed f min f max [mm/t] K = 45° Approach angle Round Inserts: Cutting speed has the Respect maximum chip For higher productivity identical radial and axial Roughing and general greatest influence on tool section area for each insert. and better chip control in forces. purposes. life. For high productivity and Amax = feed x d.o.c. roughing, work close to the High productivity fz=1.41 x h Strongest cutting edge. long tool life, first increase recommended Amax value. d.o.c. and feed rate. Recommended: • When overhang is long (lower vibration tendency) • For face milling (1st choice) 352 353

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018