Общий каталог Lamina Technologies 2019 - 2020 - страница 165

Навигация

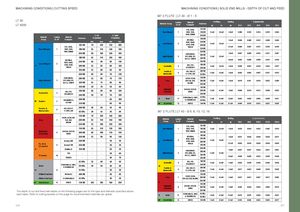

MACHINING CONDITIONS | CUTTING SPEED MACHINING CONDITIONS | SOLID END MILLS - DEPTH OF CUT AND FEED 90° 2 FLUTE | LT 40 - Ø 1 - 5 LT 40LT 4000 Material Group LaminaGr. N° MaterialExamples ProfilingHardnessapaeSlottingapØ1.0 fz [mm/tooth]Ø2.0Ø3.0Ø4.0 Ø5.0 C35, Ck45, 125 HB Non-Alloyed 1 1020, 1045, 190 HB 1.5xØ 0.5xØ 1.0xØ 0.008 0.010 0.014 0.019 0.024 LT 40 LT 4000 1060, 28Mn6 250 HB MaterialGroup Lamina MaterialGr. N°ExamplesHardness Vc [m/min] Vc [m/min]minmaxminmax125 HB70120150200 42CrMo4, 180 HB 1.0xØ 0.008 0.009 0.013 0.020 0.024Low Alloyed2PSt50, Ck60,4140, 4340,230 HB1.5xØ0.5xØ280 HB C35, Ck45,Non Alloyed11020, 1045,190 HB65110 140 190 100Cr6 350 HB 0.7xØ 0.006 0.007 0.011 0.016 0.019 1060, 28Mn6 220 HB 250 HB 60 100 120 160 X40CrMoV5, 280 HB 1.0xØ 0.007 0.008 0.012 0.017 0.021 180 HB 65 110 120 180Low Alloyed2P42CrMo4,St50, Ck60,230 HB604140, 4340,100Cr6280 HB5590859013080120High Alloyed3H13, M42, D3,1.5xØ0.5xØS6-5-2, 12Ni19320 HB0.6xØ0.0050.006 0.009 0.013 0.016350 HBAustenitic4304, 316,X5CrNi18-9180 HB1.5xØ0.5xØ1.0xØ0.006240 HB0.0070.0100.0140.017 350 HB 55 80 60 90220 HB609070130 M Ferritic &Martensitic6 410, X6Cr17,17-4 PH, 430200 HB42 HRc1.5xØ0.5xØ 1.0xØ 0.004 0.005 0.007 0.011 0.013 X40CrMoV5, 280 HB 55 80 70 110 GG20, GG40, 150 HB High Alloyed 3 H13, M42, D3, Grey 7 EN-GJL-250, 200 HB 1.5xØ 0.5xØ 1.0xØ 0.010 0.011 0.016 0.023 0.029 S6-5-2, 12Ni19 320 HB 55 75 60 90 No30B 250 HB 350 HB 50 70 50 80 K 150 HB Austenitic 4 304, 316, 180 HB 60X5CrNi18-9240 HB50807080 12070120 Malleable& Nodular8 GGG40, GGG70,50005 200 HB 1.5xØ 0.5xØ 1.0xØ 0.008 0.010 0.014 0.020 0.025250 HB M Duplex 5 X2CrNiN23-4, 290 HBS31500310 HB-- - 60 100-6090 H Steel 11 X100CrMo13, 440C, 45 HRcG-X260NiCr4250 HRc1.5xØ0.3xØ0.2xØ 0.003 0.004 0.005 0.009 0.011NFAl (>8%Si)12AlSi12130 HB1.5xØ0.5xØ0.1xØ0.0090.0100.0150.0210.026 Ferritic &Martensitic6 410, X6Cr17, 200 HB17-4PH, 43042 HRc40306045 5030 9060 90° 2 FLUTE | LT 40 - Ø 6, 8, 10, 12, 16 150 HB 70 120 140 200 GG20, GG40, EN-Grey7GJL-250,200 HB65 110 150 190N030B MaterialGroup LaminaGr. N° MaterialExamples ProfilingHardnessapaeSlottingapØ6.0 fz [mm/tooth]Ø8.0Ø10.0Ø12.0Ø16.0 250 HB 55 100 120 160K C35, Ck45, 125 HB 150 HB 65 110 130 180 Non-Alloyed 1 1020, 1045, 190 HB 1.5xØ 0.5xØ 1.0xØ 0.032 0.044 0.052 0.062 0.074 Malleable& Nodular 8 GGG40, GGG70,50005 200 HB 60 100 110 150250 HB559090130 1060, 28Mn6 250 HB42CrMo4,180 HB 1.0xØ 0.031 0.042 0.050 0.059 0.071 Incoloy 800 240 HB - - 30 50 Low Alloyed 2P St50, Ck60,4140, 4340,230 HB1.5xØ 0.5xØ280 HB Fe, Ni &Co based 9 Inconel 700 250 HB - - 30 50 100Cr6 350 HB 0.7xØ 0.026 0.034 0.042 0.050 0.059 S Stellite 21 350 HB - - 20 50 220 HBX40CrMoV5,280 HB 1.0xØ 0.027 0.037 0.044 0.051 0.061 T40 - - - 30 60Ti based10TiAl6V4---4070 High Alloyed 3 H13, M42, D3, 1.5xØ 0.5xØS6-5-2, 12Ni19320 HB0.6xØ0.0200.028 0.033 0.039 0.046350 HB 45 HRc 35 60 40 60SteelX100CrMo13, 440C,G-X260NiCr4250 HRc30504060H1155 HRc--3050Austenitic4304, 316,X5CrNi18-9180 HB1.5xØ 0.5xØ 1.0xØ 0.022240 HB0.030 0.036 0.042 0.050MFerritic &Martensitic6410, X6Cr17,17-4 PH, 430200 HB1.5xØ42 HRc0.5xØ1.0xØ0.0170.0230.0280.0320.039 Chilled Cast Iron Ni-Hard 2 400 HB - - 40 60 150 HB White Cast Iron G-X300CrMo15 55 HRc - - 30 50 Grey 7 GG20, GG40,EN-GJL-250, No30B200 HB1.5xØ0.5xØ 1.0xØ 0.037 0.051 0.061 0.071 0.085 250 HB NF Aluminium 12 AlSi12 130 HB 120 180 160 250 K 150 HB Malleable& Nodular8 GGG40, GGG70,50005 200 HB 1.5xØ 0.5xØ 1.0xØ 0.032 0.044 0.052 0.062 0.074 The depth of cut and feed rate tables on the following pages are for the type and diameter specified above 250 HB each table. Refer to cutting speeds on this page for recommended materials per grade. H Steel 11 X100CrMo13, 440C, 45 HRcG-X260NiCr4250 HRc1.5xØ0.3xØ0.2xØ 0.014 0.019 0.022 0.026 0.031 NF Al (>8%Si) 12 AlSi12 130 HB 1.5xØ 0.5xØ 0.1xØ 0.034 0.046 0.055 0.065 0.077 326 327

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018