Общий каталог Lamina Technologies 2019 - 2020 - страница 128

Навигация

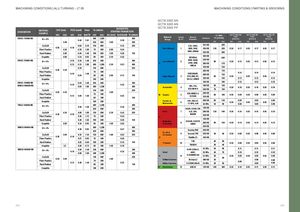

MACHINING CONDITIONS | ALU TURNING - LT 05 MACHINING CONDITIONS | PARTING & GROOVING GCTX 2002 NN GCTX 3003 NN DESIGNATION MATERIAL DOC (mm) FEED (mm/t) Amax Vc (m/min) SUGGESTEDSTARTING PARAMETERSEXAMPLEminmaxminmax(mm^2)minmaxdoc (mm)feed (mm/t)Vc (m/mm)DNGG 110408 NSSi < 4%4001,2004000.461.610.305.002506003.00300GCTX 3003 PPMaterialGroupLT 1000LaminaGr. N°MaterialExamplesHardnessVc [m/min]GCTX 2002 NNGCTX 3003 NNGCTX 3003 PPFeedFeedFeed[mm/rev][mm/rev][mm/rev]minmaxminmaxminmaxminmax CuZn30 0.60 2.10 150 800 0.35 250 C35, Ck45, 125 HB 220 0.50 0.18Fiber Plastics4.500.381.2070500 2.80 0.24Hard Rubber5.000.401.401002003.000.28150 Non Alloyed 1 1020, 1045, 190 HB 130 220 0.50 0.17 0.05 0.17 0.05 0.171060, 28Mn6250 HB200 Graphite 4.00 0.34 0.95 80 300 2.50 0.22 42CrMo4, 180 HB 200 DNGG 150604 NS Si < 4% 0.10 0.30 1.40 250 600 3000.120.351.804001,2002.500.23400CuZn300.30150800250Low AlloyedP 2 St50, Ck60,4140, 4340,230 HB280 HB90 0.50 0.15 0.05 0.15 0.05 0.15170100Cr6350 HB150 0.30 5.50Fiber Plastics 70 5000.101.40Hard Rubber0.20803002.000.15150 220 HB 170X40CrMoV5,280 HB1500.14 0.14 0.14High Alloyed3H13, M42, D3,600.500.050.05 Graphite 100 200 S6-5-2, 12Ni19 320 HB 130 0.13 0.13 0.13 DNGG 150608 NS Si < 4%WNGG 080408 NS 0.50 1.40 250 600 3000.180.320.601.804001,200400CuZn30150800250 350 HB 100 0.12 0.12 0.12Austenitic4304, 316,180 HB90X5CrNi18-9240 HB701500.500.100.050.100.050.10140 0.50 5.50 3.00Fiber Plastics705000.150.401.400.25Hard Rubber80300150M Duplex 5 X2CrNiN23-4, 290 HBS31500310 HB60 100 0.50 0.09 0.05 0.09 0.05 0.09 GraphiteTNGG 160408 NSSi < 4% 100 2004001,200 400 Ferritic &Martensitic6 410, X6Cr17, 200 HB 6017-4PH, 43042 HRc50130 0.09 0.09 0.090.500.050.05900.080.080.080.501.580.36250600300GG20, GG40, EN-150 HB CuZn30 4.50 0.60 1.89 150 800 2.30 0.45 250 Grey 7 GJL-250, 200 HB 130 190 0.50 0.16 0.05 0.16 0.05 0.16 0.30 0.18Fiber Plastics0.361.1370 500 0.24 N030B 250 HBK Hard Rubber 0.40 1.26 100 200 0.26 150Graphite4.000.340.95803001.600.22 150 HBMalleable& Nodular8GGG40, GGG70,50005200 HB901500.500.140.050.14 0.05 0.14 WNGG 060404 NS Si < 4% 400 1,200 4000.300.950.27250600300CuZn303.000.351.101508001.800.25250 250 HBIncoloy 800240 HBFe, Ni &Co based9Inconel 700250 HB30400.500.080.050.080.05 0.08 0.30 0.10Fiber Plastics0.270.8570 500 0.20 S Stellite 21 350 HB Hard Rubber 0.22 0.69 100 200 0.16 150 T40 - 40 60Ti based100.50 0.08 0.05 0.08 0.05 0.08 Graphite 2.5 0.26 0.73 80 300 1.60 0.18 TiAl6V4 - 30 40 WNGG 060408 NS Si < 4% 0.50 1.40 250 600 3000.180.320.601.804001,200400CuZn301508002500.503.001.80Fiber Plastics705000.150.401.400.25Hard Rubber80300150X100 CrMo13,45 HRc50 90 0.11 0.11 0.11Steel440C,50 HRc40700.100.100.10H11G-X260NiCr4255 HRc300.500.090.050.090.050.0960Chilled Cast IronNi-Hard 2400 HB40White Cast IronG-X300CrMo1555 HRc30500.080.080.080.080.08 Graphite 100 200 NF Aluminium 12 AlSi12 130 HB 100 300 0.50 0.10 0.05 0.11 0.05 0.11 252 253

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018