Основной каталог Kyocera 2016-2017 - страница 949

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

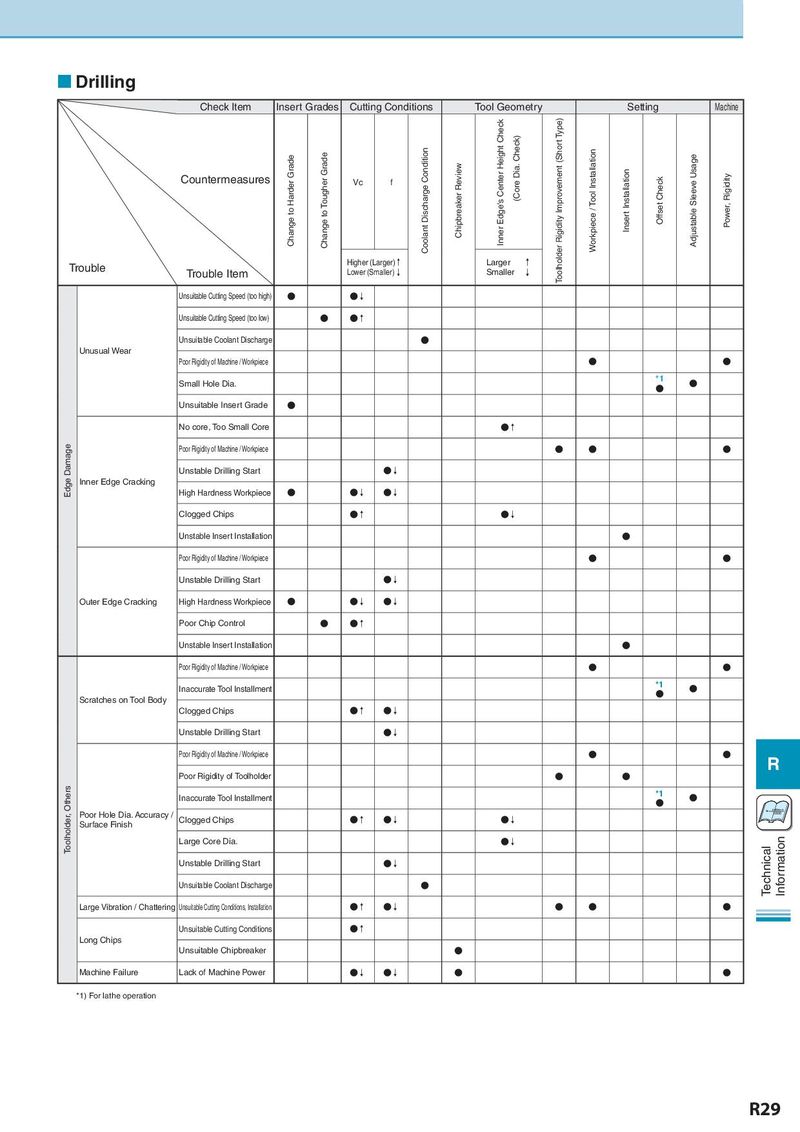

Drilling Check Item Insert Grades Cutting Conditions Tool Geometry Setting Machine Countermeasures Change to Harder Grade Change to Tougher Grade Vc f Coolant Discharge Condition Chipbreaker Review Inner Edge's Center Height Check (Core Dia. Check) Toolholder Rigidity Improvement (Short Type) Workpiece / Tool Installation Insert Installation Offset Check Adjustable Sleeve Usage Power, Rigidity Trouble Higher (Larger)↑ Larger ↑ Trouble Item Lower (Smaller)↓ Smaller ↓ Unsuitable Cutting Speed (too high) ● ●↓ Unsuitable Cutting Speed (too low) ● ●↑ Unsuitable Coolant Discharge ● Unusual Wear Poor Rigidity of Machine / Workpiece ● ● Small Hole Dia. *1 ● ● Unsuitable Insert Grade ● No core, Too Small Core ●↑ Edge Damage Poor Rigidity of Machine / Workpiece ● ● ● Unstable Drilling Start ●↓ Inner Edge Cracking High Hardness Workpiece ● ●↓ ●↓ Clogged Chips ●↑ ●↓ Unstable Insert Installation ● Poor Rigidity of Machine / Workpiece ● ● Unstable Drilling Start ●↓ Outer Edge Cracking High Hardness Workpiece ● ●↓ ●↓ Poor Chip Control ● ●↑ Unstable Insert Installation ● Poor Rigidity of Machine / Workpiece ● ● Inaccurate Tool Installment *1 ● Scratches on Tool Body ● Clogged Chips ●↑ ●↓ Unstable Drilling Start ●↓ Poor Rigidity of Machine / Workpiece ● ● R Poor Rigidity of Toolholder ● ● Others Inaccurate Tool Installment *1 ● ● Vc= π×Dm×n Toolholder, Poor Hole Dia. Accuracy / Clogged Chips ●↑ ●↓ ●↓ Surface Finish Large Core Dia. ●↓ Information Unstable Drilling Start ●↓ Technical Unsuitable Coolant Discharge ● Large Vibration / Chattering Unsuitable Cutting Conditions, Installation ●↑ ●↓ ● ● ● Unsuitable Cutting Conditions ●↑ Long Chips Unsuitable Chipbreaker ● Machine Failure Lack of Machine Power ●↓ ●↓ ● ● *1) For lathe operation R29