Основной каталог Kyocera 2016-2017 - страница 946

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

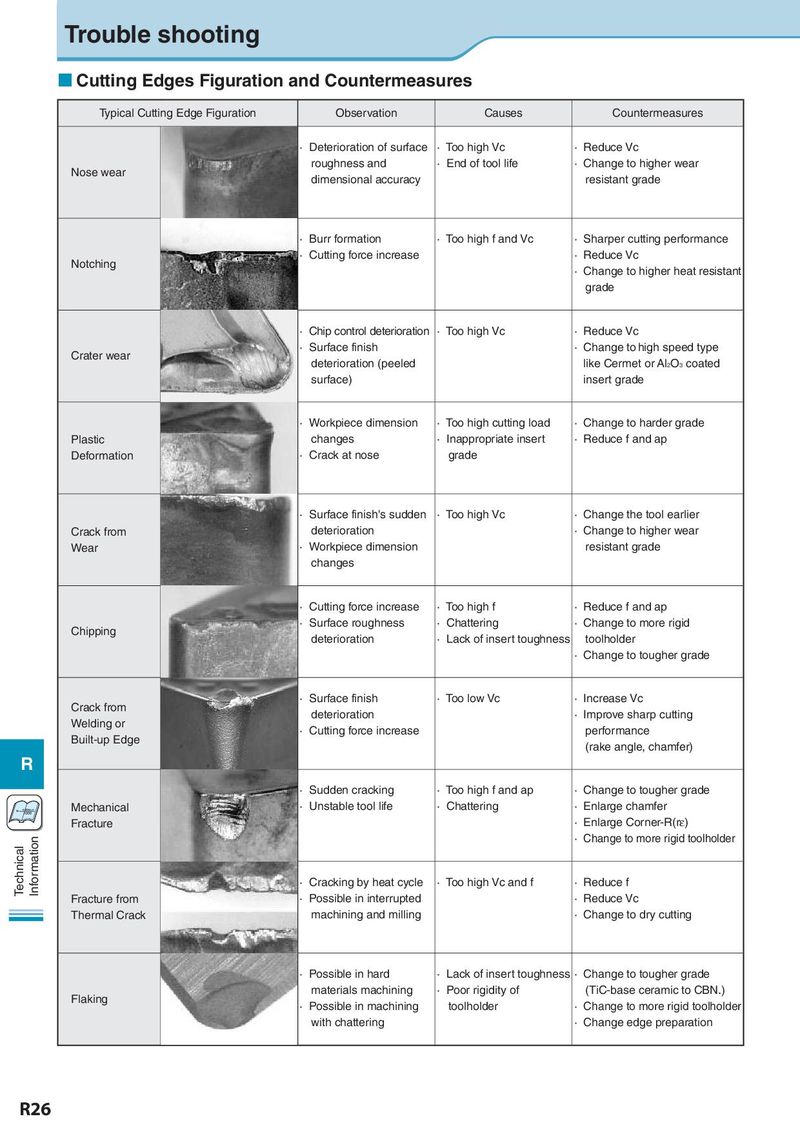

Trouble shooting Cutting Edges Figuration and Countermeasures Typical Cutting Edge Figuration Observation Causes Countermeasures · Deterioration of surface · Too high Vc · Reduce Vc Nose wear roughness and · End of tool life · Change to higher wear dimensional accuracy resistant grade · Burr formation · Too high f and Vc · Sharper cutting performance Notching · Cutting force increase · Reduce Vc · Change to higher heat resistant grade · Chip control deterioration · Too high Vc · Reduce Vc Crater wear · Surface finish · Change to high speed type deterioration (peeled like Cermet or Al2O3 coated surface) insert grade · Workpiece dimension · Too high cutting load · Change to harder grade Plastic changes · Inappropriate insert · Reduce f and ap Deformation · Crack at nose grade · Surface finish's sudden · Too high Vc · Change the tool earlier Crack from deterioration · Change to higher wear Wear · Workpiece dimension resistant grade changes · Cutting force increase · Too high f · Reduce f and ap Chipping · Surface roughness · Chattering · Change to more rigid deterioration · Lack of insert toughness toolholder · Change to tougher grade Crack from · Surface finish · Too low Vc · Increase Vc Welding or deterioration · Improve sharp cutting Built-up Edge · Cutting force increase performance (rake angle, chamfer) R · Sudden cracking · Too high f and ap · Change to tougher grade Vc= π×Dm×n Mechanical · Unstable tool life · Chattering · Enlarge chamfer Fracture · Enlarge Corner-R(rε) Information · Change to more rigid toolholder Technical · Cracking by heat cycle · Too high Vc and f · Reduce f Fracture from · Possible in interrupted · Reduce Vc Thermal Crack machining and milling · Change to dry cutting · Possible in hard · Lack of insert toughness · Change to tougher grade Flaking materials machining · Poor rigidity of (TiC-base ceramic to CBN.) · Possible in machining toolholder · Change to more rigid toolholder with chattering · Change edge preparation R26