Основной каталог Kyocera 2016-2017 - страница 892

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

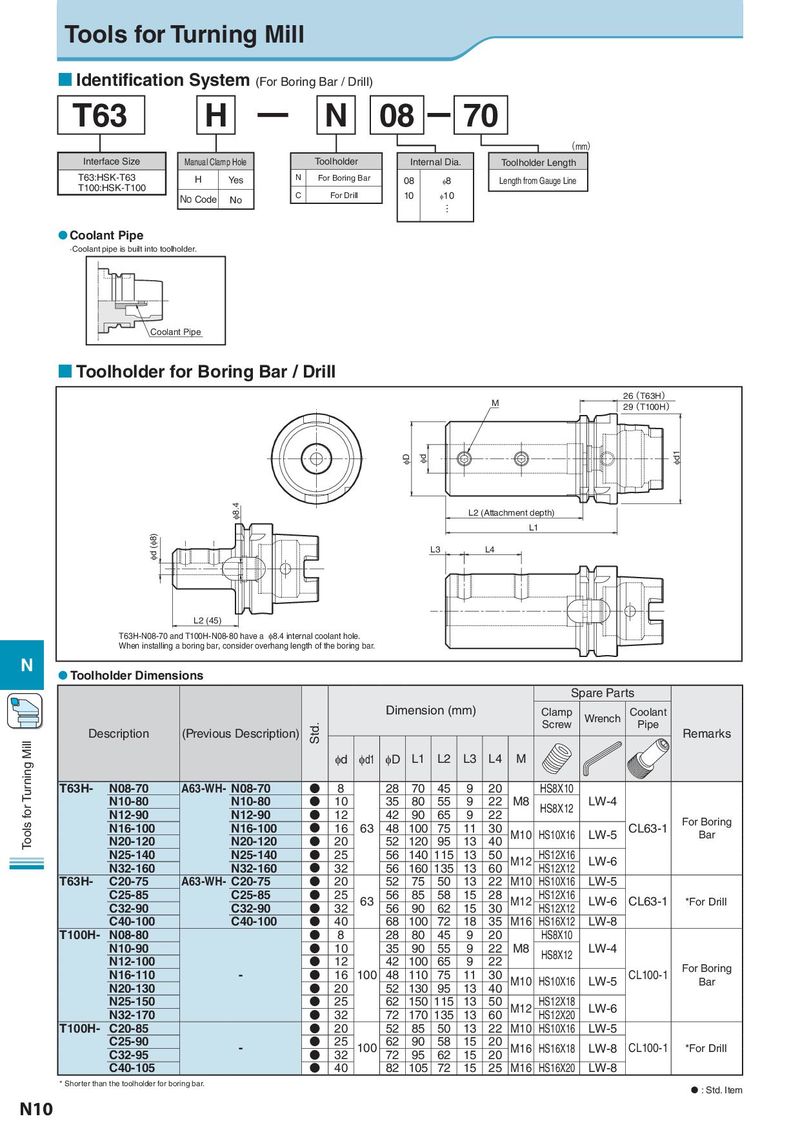

Tools for Turning Mill Identification System (For Boring Bar / Drill) T63 H N 08 70 (mm) Interface Size Manual Clamp Hole Toolholder Internal Dia. Toolholder Length T63:HSK-T63 H Yes N For Boring Bar 08 φ8 Length from Gauge Line T100:HSK-T100 C For Drill 10 φ1… 0 No Code No Coolant Pipe ·Coolant pipe is built into toolholder. Coolant Pipe Toolholder for Boring Bar / Drill M 26(T63H) 29(T100H) ID Id Id1 I8.4 L2 (Attachment depth) L1 Id (I8) L3 L4 L2 (45) T63H-N08-70 and T100H-N08-80 have a I8.4 internal coolant hole. When installing a boring bar, consider overhang length of the boring bar. N Toolholder Dimensions Spare Parts Dimension (mm) Clamp Wrench Coolant Description (Previous Description) Std. Screw Pipe Remarks Mill φd φd1 φD L1 L2 L3 L4 M Turning T63H- N08-70 A63-WH- N08-70 N 8 28 70 45 9 20 HS8X10 fo r N10-80 N10-80 N 10 35 80 55 9 22 M8 HS8X12 LW-4 N12-90 N12-90 N 12 42 90 65 9 22 For Boring Tools N16-100 N16-100 N 16 63 48 100 75 11 30 M10 HS10X16 LW-5 CL63-1 Bar N20-120 N20-120 N 20 52 120 95 13 40 N25-140 N25-140 N 25 56 140 115 13 50 M12 HS12X16 LW-6 N32-160 N32-160 N 32 56 160 135 13 60 HS12X12 T63H- C20-75 A63-WH- C20-75 N 20 52 75 50 13 22 M10 HS10X16 LW-5 C25-85 C25-85 N 25 63 56 85 58 15 28 M12 HS12X16 LW-6 CL63-1 *For Drill C32-90 C32-90 N 32 56 90 62 15 30 HS12X12 C40-100 C40-100 N 40 68 100 72 18 35 M16 HS16X12 LW-8 T100H- N08-80 N 8 28 80 45 9 20 HS8X10 N10-90 N 10 35 90 55 9 22 M8 HS8X12 LW-4 N12-100 N 12 42 100 65 9 22 For Boring N16-110 - N 16 100 48 110 75 11 30 M10 HS10X16 LW-5 CL100-1 Bar N20-130 N 20 52 130 95 13 40 N25-150 N 25 62 150 115 13 50 M12 HS12X18 LW-6 N32-170 N 32 72 170 135 13 60 HS12X20 T100H- C20-85 N 20 52 85 50 13 22 M10 HS10X16 LW-5 C25-90 - N 25 100 62 90 58 15 20 M16 HS16X18 LW-8 CL100-1 *For Drill C32-95 N 32 72 95 62 15 20 C40-105 N 40 82 105 72 15 25 M16 HS16X20 LW-8 * Shorter than the toolholder for boring bar. : Std. Item N10