Основной каталог Kyocera 2016-2017 - страница 881

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

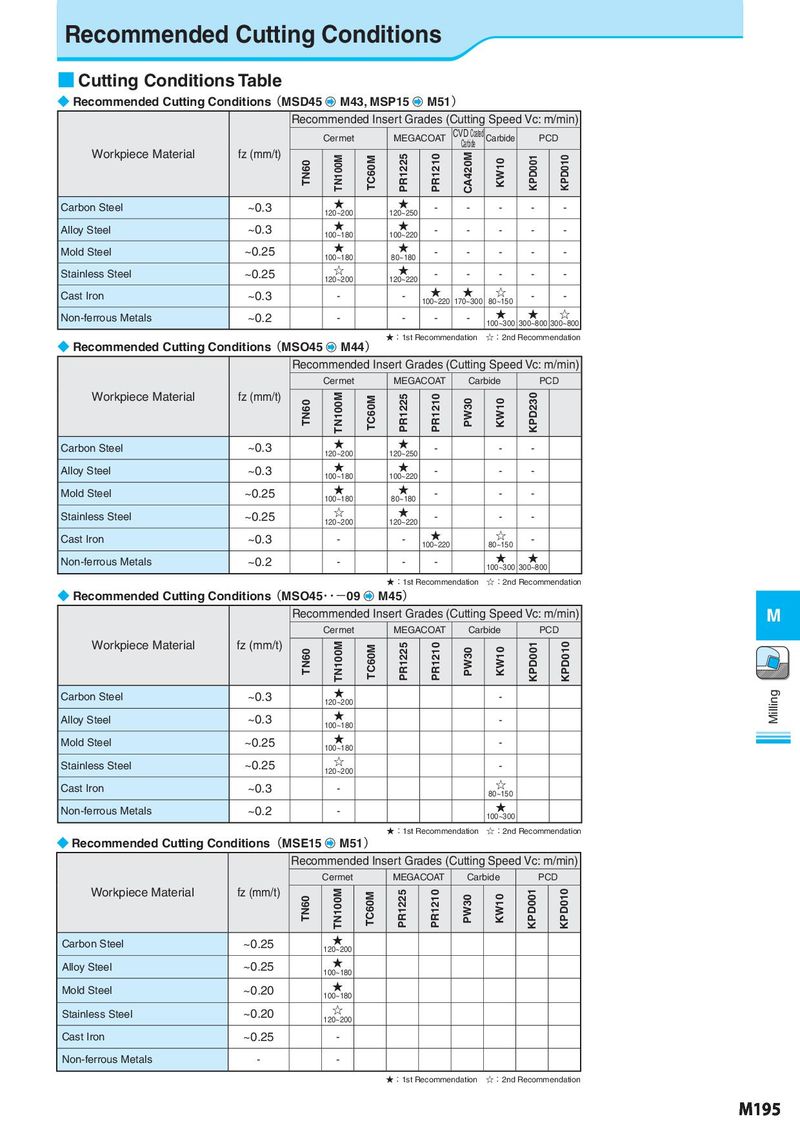

Recommended Cutting Conditions ■ Cutting Conditions Table ◆ Recommended Cutting Conditions( MSD45 M43, MSP15 M51) Recommended Insert Grades (Cutting Speed Vc: m/min) Cermet MEGACOAT CVD Coated Carbide PCD Carbide Workpiece Material fz (mm/t) TN60 TN100M TC60M PR1225 PR1210 CA420M KW10 KPD001 KPD010 Carbon Steel ~0.3 ★ ★ - - - - - 120~200 120~250 Alloy Steel ~0.3 ★ ★ - - - - - 100~180 100~220 Mold Steel ~0.25 ★ ★ - - - - - 100~180 80~180 Stainless Steel ~0.25 ☆ ★ - - - - - 120~200 120~220 Cast Iron ~0.3 - - ★ ★ ☆ - - 100~220 170~300 80~150 Non-ferrous Metals ~0.2 - - - - ★ ★ ☆ 100~300 300~800 300~800 ★:1st Recommendation ☆:2nd Recommendation ◆ Recommended Cutting Conditions( MSO45 M44) Recommended Insert Grades (Cutting Speed Vc: m/min) Cermet MEGACOAT Carbide PCD Workpiece Material fz (mm/t) TN60 TN100M TC60M PR1225 PR1210 PW30 KW10 KPD230 Carbon Steel ~0.3 ★ ★ - - - 120~200 120~250 Alloy Steel ~0.3 ★ ★ - - - 100~180 100~220 Mold Steel ~0.25 ★ ★ - - - 100~180 80~180 Stainless Steel ~0.25 ☆ ★ - - - 120~200 120~220 Cast Iron ~0.3 - - ★ ☆ - 100~220 80~150 Non-ferrous Metals ~0.2 - - - ★ ★ 100~300 300~800 ★:1st Recommendation ☆:2nd Recommendation ◆ Recommended Cutting Conditions( MSO45・・-09 M45) Recommended Insert Grades (Cutting Speed Vc: m/min) M Cermet MEGACOAT Carbide PCD Workpiece Material fz (mm/t) TN60 TN100M TC60M PR1225 PR1210 PW30 KW10 KPD001 KPD010 Carbon Steel ~0.3 ★ - Milling 120~200 Alloy Steel ~0.3 ★ - 100~180 Mold Steel ~0.25 ★ - 100~180 Stainless Steel ~0.25 ☆ - 120~200 Cast Iron ~0.3 - ☆ 80~150 Non-ferrous Metals ~0.2 - ★ 100~300 ★:1st Recommendation ☆:2nd Recommendation ◆ Recommended Cutting Conditions(MSE15 M51) Recommended Insert Grades (Cutting Speed Vc: m/min) Cermet MEGACOAT Carbide PCD Workpiece Material fz (mm/t) TN60 TN100M TC60M PR1225 PR1210 PW30 KW10 KPD001 KPD010 Carbon Steel ~0.25 ★ 120~200 Alloy Steel ~0.25 ★ 100~180 Mold Steel ~0.20 ★ 100~180 Stainless Steel ~0.20 ☆ 120~200 Cast Iron ~0.25 - Non-ferrous Metals - - ★:1st Recommendation ☆:2nd Recommendation M195