Основной каталог Kyocera 2016-2017 - страница 873

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

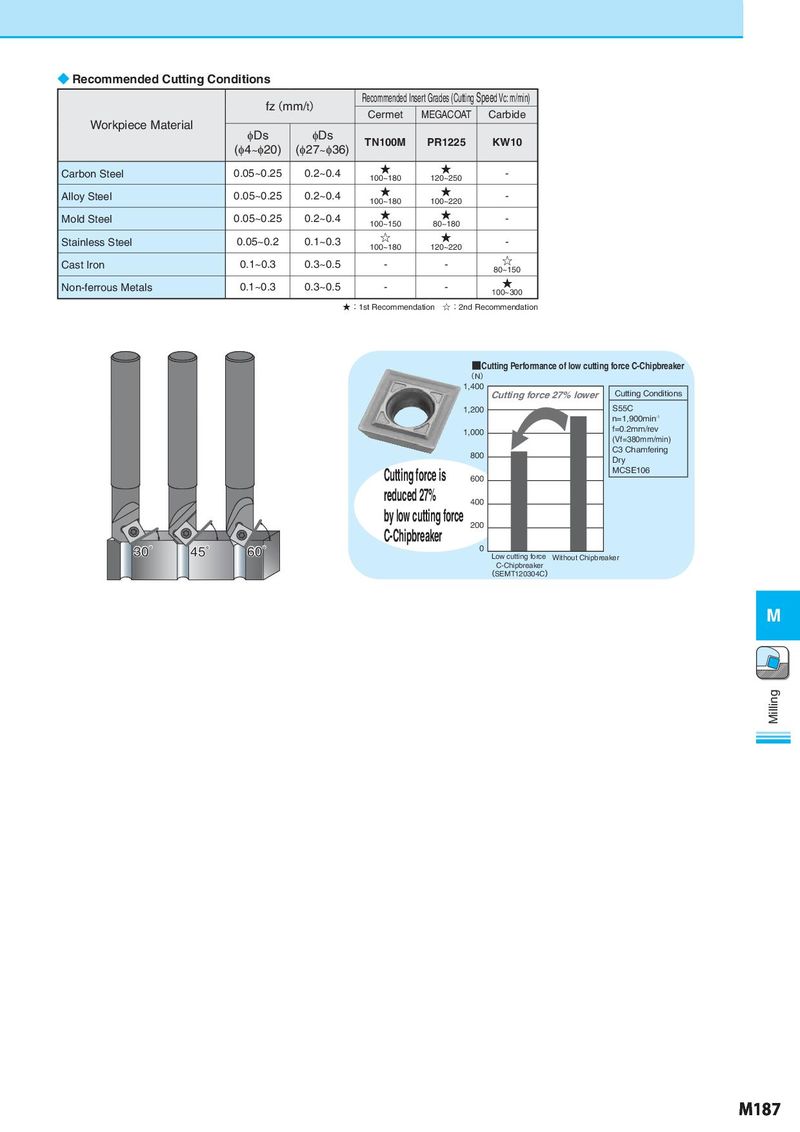

◆ Recommended Cutting Conditions fz(mm/t) Recommended Insert Grades (Cutting Speed Vc: m/min) Cermet MEGACOAT Carbide Workpiece Material φDs φDs (φ4~φ20) (φ27~φ36) TN100M PR1225 KW10 Carbon Steel 0.05~0.25 0.2~0.4 ★ ★ - 100~180 120~250 Alloy Steel 0.05~0.25 0.2~0.4 ★ ★ - 100~180 100~220 Mold Steel 0.05~0.25 0.2~0.4 ★ ★ - 100~150 80~180 Stainless Steel 0.05~0.2 0.1~0.3 ☆ ★ - 100~180 120~220 Cast Iron 0.1~0.3 0.3~0.5 - - ☆ 80~150 Non-ferrous Metals 0.1~0.3 0.3~0.5 - - ★ 100~300 ★:1st Recommendation ☆:2nd Recommendation ■Cutting Performance of low cutting force C-Chipbreaker (N) 1,400 Cutting force 27% lower Cutting Conditions 1,200 S55C n=1,900min-1 1,000 f=0.2mm/rev (Vf=380mm/min) 800 C3 Chamfering Dry Cutting force is MCSE106 600 reduced 27% 400 by low cutting force 200 C-Chipbreaker 30˚ 45˚ 60˚ 0 Low cutting force Without Chipbreaker C-Chipbreaker (SEMT120304C) M Milling M187