Основной каталог Kyocera 2016-2017 - страница 871

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

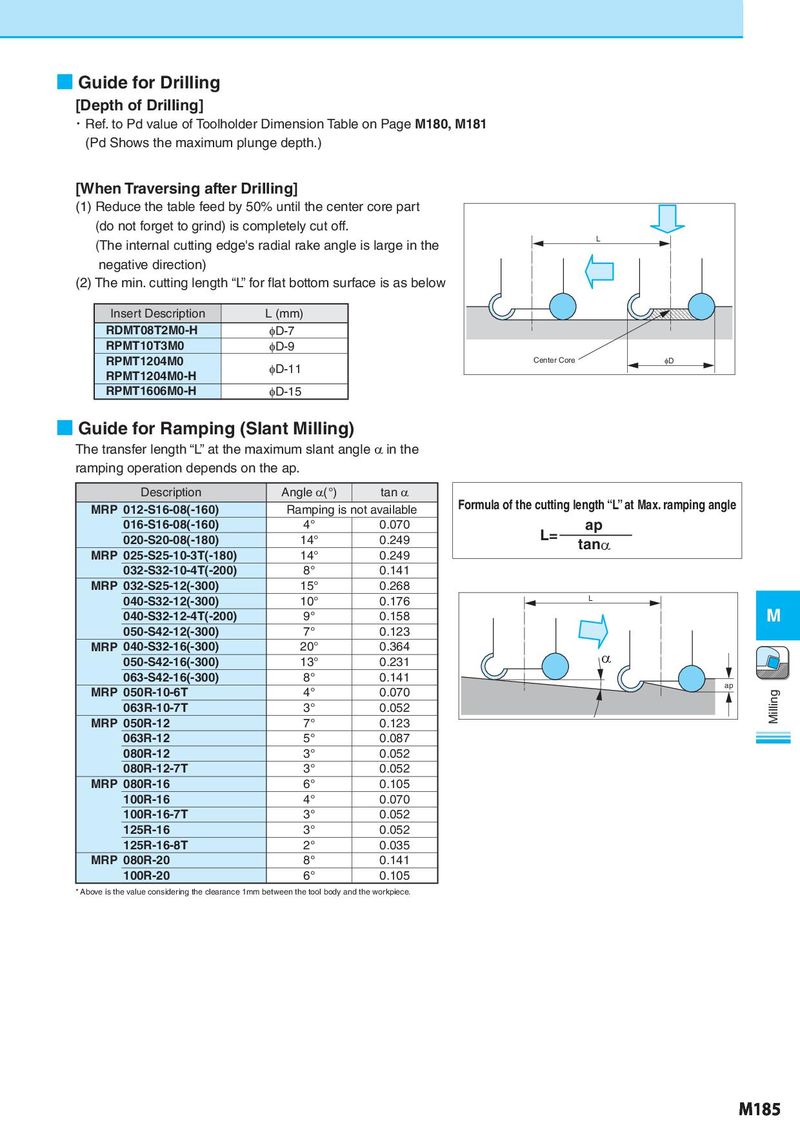

■ Guide for Drilling [Depth of Drilling] ・Ref. to Pd value of Toolholder Dimension Table on Page M180, M181 (Pd Shows the maximum plunge depth.) [When Traversing after Drilling] (1) Reduce the table feed by 50% until the center core part (do not forget to grind) is completely cut off. (The internal cutting edge's radial rake angle is large in the L negative direction) (2) The min. cutting length “L” for flat bottom surface is as below Insert Description L (mm) RDMT08T2M0-H φD-7 RPMT10T3M0 φD-9 RPMT1204M0 Center Core φD RPMT1204M0-H φD-11 RPMT1606M0-H φD-15 ■ Guide for Ramping (Slant Milling) The transfer length “L” at the maximum slant angle α in the ramping operation depends on the ap. Description Angle α(°) tan α MRP 012-S16-08(-160) Ramping is not available Formula of the cutting length “L” at Max. ramping angle 016-S16-08(-160) 4° 0.070 L= ap 020-S20-08(-180) 14° 0.249 tanα MRP 025-S25-10-3T(-180) 14° 0.249 032-S32-10-4T(-200) 8° 0.141 MRP 032-S25-12(-300) 15° 0.268 040-S32-12(-300) 10° 0.176 L 040-S32-12-4T(-200) 9° 0.158 M 050-S42-12(-300) 7° 0.123 MRP 040-S32-16(-300) 20° 0.364 α 050-S42-16(-300) 13° 0.231 063-S42-16(-300) 8° 0.141 ap MRP 050R-10-6T 4° 0.070 Milling 063R-10-7T 3° 0.052 MRP 050R-12 7° 0.123 063R-12 5° 0.087 080R-12 3° 0.052 080R-12-7T 3° 0.052 MRP 080R-16 6° 0.105 100R-16 4° 0.070 100R-16-7T 3° 0.052 125R-16 3° 0.052 125R-16-8T 2° 0.035 MRP 080R-20 8° 0.141 100R-20 6° 0.105 * Above is the value considering the clearance 1mm between the tool body and the workpiece. M185