Основной каталог Kyocera 2016-2017 - страница 821

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

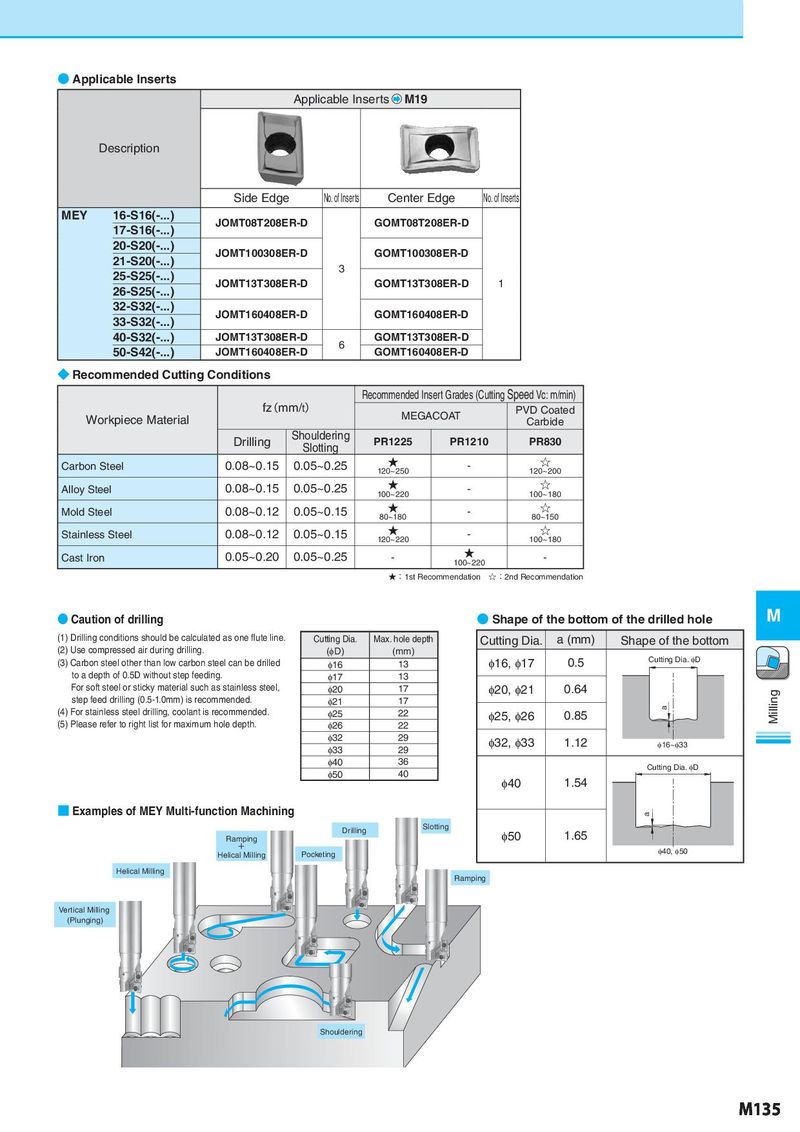

● Applicable Inserts Applicable Inserts M19 Description Side Edge No. of Inserts Center Edge No. of Inserts MEY 16-S16(-...) JOMT08T208ER-D GOMT08T208ER-D 17-S16(-...) 20-S20(-...) JOMT100308ER-D GOMT100308ER-D 21-S20(-...) 3 25-S25(-...) JOMT13T308ER-D GOMT13T308ER-D 1 26-S25(-...) 32-S32(-...) JOMT160408ER-D GOMT160408ER-D 33-S32(-...) 40-S32(-...) JOMT13T308ER-D 6 GOMT13T308ER-D 50-S42(-...) JOMT160408ER-D GOMT160408ER-D ◆ Recommended Cutting Conditions Recommended Insert Grades (Cutting Speed Vc: m/min) fz(mm/t) MEGACOAT PVD Coated Workpiece Material Carbide Drilling Shouldering PR1225 PR1210 PR830 Slotting Carbon Steel 0.08~0.15 0.05~0.25 ★ - ☆ 120~250 120~200 Alloy Steel 0.08~0.15 0.05~0.25 ★ - ☆ 100~220 100~180 Mold Steel 0.08~0.12 0.05~0.15 ★ - ☆ 80~180 80~150 Stainless Steel 0.08~0.12 0.05~0.15 ★ - ☆ 120~220 100~180 Cast Iron 0.05~0.20 0.05~0.25 - ★ - 100~220 ★:1st Recommendation ☆:2nd Recommendation ● Caution of drilling ● Shape of the bottom of the drilled hole M (1) Drilling conditions should be calculated as one flute line. Cutting Dia. Max. hole depth Cutting Dia. a (mm) Shape of the bottom (2) Use compressed air during drilling. (φD) (mm) (3) Carbon steel other than low carbon steel can be drilled φ16 13 φ16, φ17 0.5 Cutting Dia. φD to a depth of 0.5D without step feeding. φ17 13 For soft steel or sticky material such as stainless steel, φ20 17 φ20, φ21 0.64 Milling step feed drilling (0.5-1.0mm) is recommended. φ21 17 (4) For stainless steel drilling, coolant is recommended. 22 a φ25 φ25, φ26 0.85 (5) Please refer to right list for maximum hole depth. φ26 22 φ32 29 φ32, φ33 1.12 φ16~φ33 φ33 29 φ40 36 Cutting Dia. φD Cutting Dia. φD φ50 40 φ40 1.54 ■ Examples of MEY Multi-function Machining a a Drilling Slotting Ramping φ50 1.65 + φ16~φ33 φ40, φ50 Helical Milling Pocketing Helical Milling Ramping Vertical Milling (Plunging) Shouldering M135