Основной каталог Kyocera 2016-2017 - страница 818

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

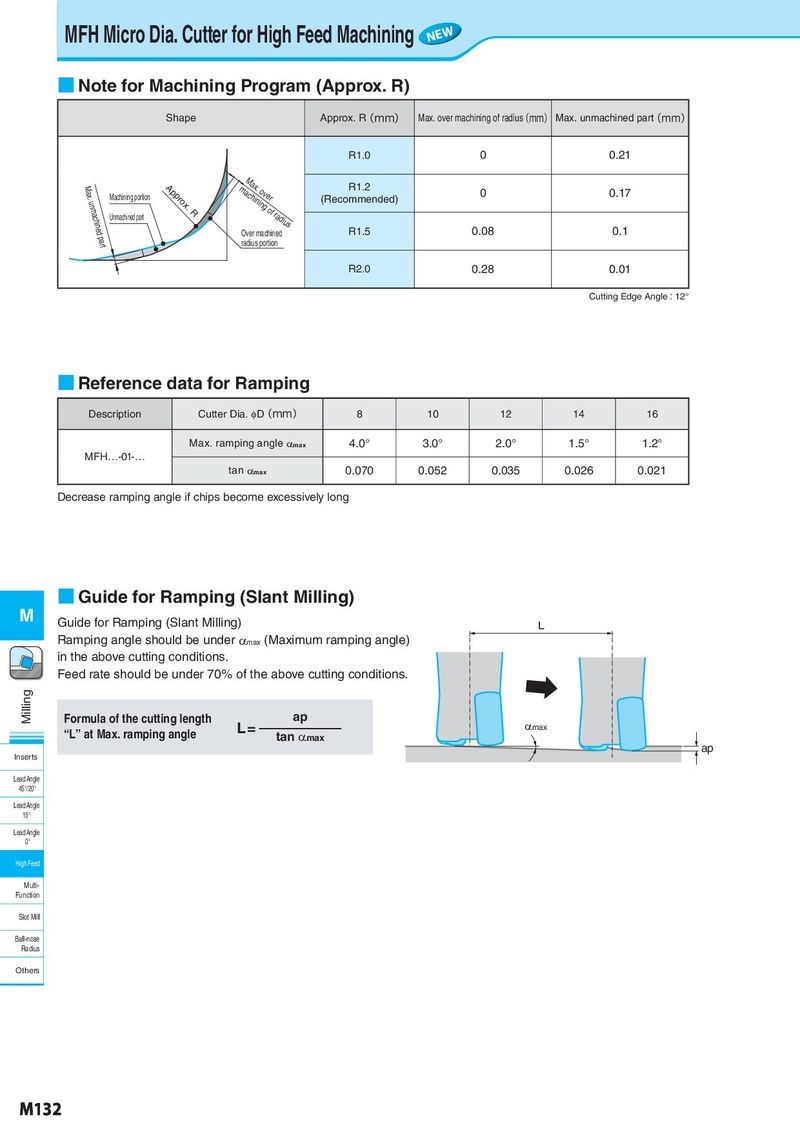

MFH Micro Dia. Cutter for High Feed Machining NEW ■ Note for Machining Program (Approx. R) Shape Approx. R(mm) Max. over machining of radius(mm) Max. unmachined part(mm) R1.0 0 0.21 Max. unmachined part Approx. R maMchaixn.inogveorf radius R1.2 0 0.17 Machining portion (Recommended) Unmachined part Over machined R1.5 0.08 0.1 radius portion R2.0 0.28 0.01 Cutting Edge Angle:12° ■ Reference data for Ramping Description Cutter Dia. φD(mm) 8 10 12 14 16 Max. ramping angle αmax 4.0° 3.0° 2.0° 1.5° 1.2° MFH…-01-… tan αmax 0.070 0.052 0.035 0.026 0.021 Decrease ramping angle if chips become excessively long ■ Guide for Ramping (Slant Milling) M Guide for Ramping (Slant Milling) L Ramping angle should be under αmax (Maximum ramping angle) in the above cutting conditions. Feed rate should be under 70% of the above cutting conditions. Milling Formula of the cutting length L= ap αmax “L” at Max. ramping angle tan αmax Inserts ap Lead Angle 45°/20° Lead Angle 15° Lead Angle 0° High Feed Multi- Function Slot Mill Ball-nose Radius Others M132