Основной каталог Kyocera 2016-2017 - страница 799

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

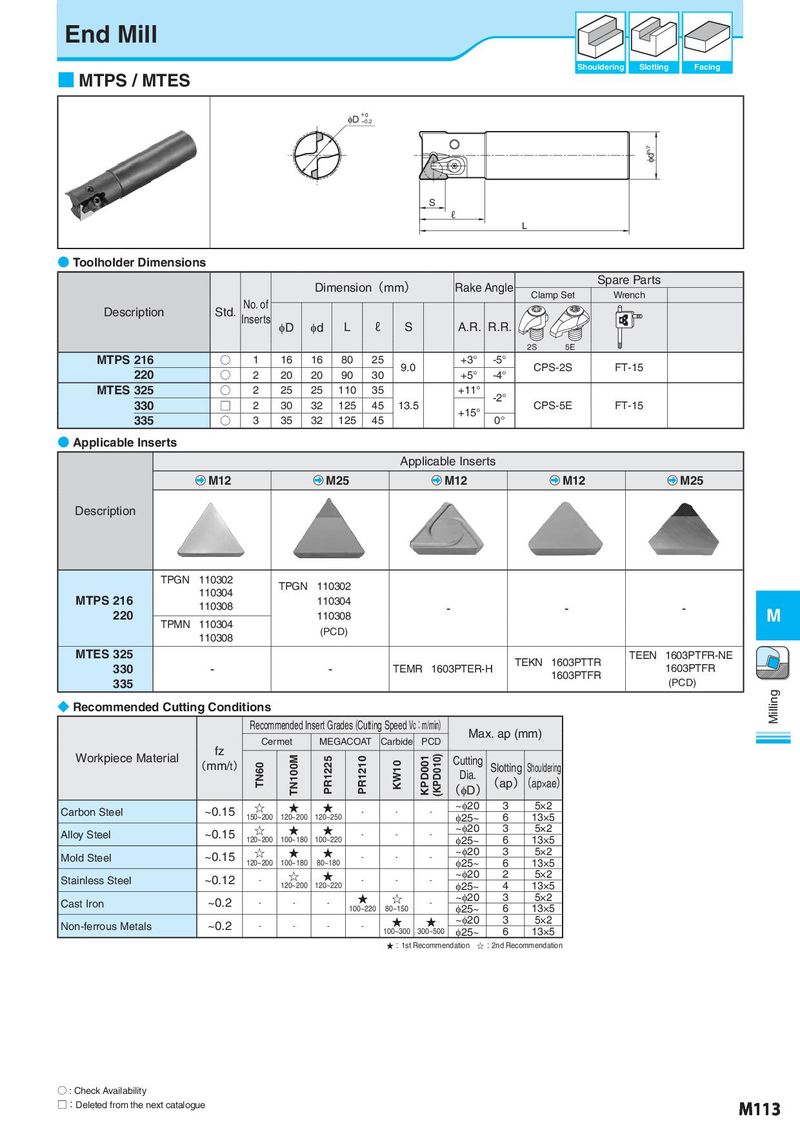

End Mill Shouldering Slotting Facing ■ MTPS / MTES φD +0 −0.2 φdh7 S ℓ L ● Toolholder Dimensions Dimension(mm) Rake Angle Spare Parts Clamp Set Wrench Description Std. No. of Inserts φD φd L ℓ S A.R. R.R. 2S 5E MTPS 216 ○ 1 16 16 80 25 9.0 +3° -5° CPS-2S FT-15 220 ○ 2 20 20 90 30 +5° -4° MTES 325 ○ 2 25 25 110 35 +11° -2° 330 □ 2 30 32 125 45 13.5 +15° CPS-5E FT-15 335 ○ 3 35 32 125 45 0° ● Applicable Inserts Applicable Inserts M12 M25 M12 M12 M25 Description TPGN 110302 TPGN 110302 MTPS 216 110304 110304 220 110308 - - - M TPMN 110304 110308 110308 (PCD) MTES 325 TEKN 1603PTTR TEEN 1603PTFR-NE 330 - - TEMR 1603PTER-H 1603PTFR 1603PTFR 335 (PCD) ◆ Recommended Cutting Conditions Milling Recommended Insert Grades (Cutting Speed Vc:m/min) Max. ap (mm) fz Cermet MEGACOAT Carbide PCD Workpiece Material (mm/t) TN60 TN100M PR1225 PR1210 KW10 KPD001 (KPD010) (CDuφtiDtain.)g (Sloatptin)g(Shaopu×ldaerein)g Carbon Steel ~0.15 ☆ ★ ★ - - - ~φ20 3 5×2 150~200 120~200 120~250 φ25~ 6 13×5 Alloy Steel ~0.15 ☆ ★ ★ - - - ~φ20 3 5×2 120~200 100~180 100~220 φ25~ 6 13×5 Mold Steel ~0.15 ☆ ★ ★ - - - ~φ20 3 5×2 120~200 100~180 80~180 φ25~ 6 13×5 Stainless Steel ~0.12 - ☆ ★ - - - ~φ20 2 5×2 120~200 120~220 φ25~ 4 13×5 Cast Iron ~0.2 - - - ★ ☆ - ~φ20 3 5×2 100~220 80~150 φ25~ 6 13×5 Non-ferrous Metals ~0.2 - - - - ★ ★ ~φ20 3 5×2 100~300 300~500 φ25~ 6 13×5 ★:1st Recommendation ☆:2nd Recommendation ○ : Check Availability □:Deleted from the next catalogue M113