Основной каталог Kyocera 2016-2017 - страница 767

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

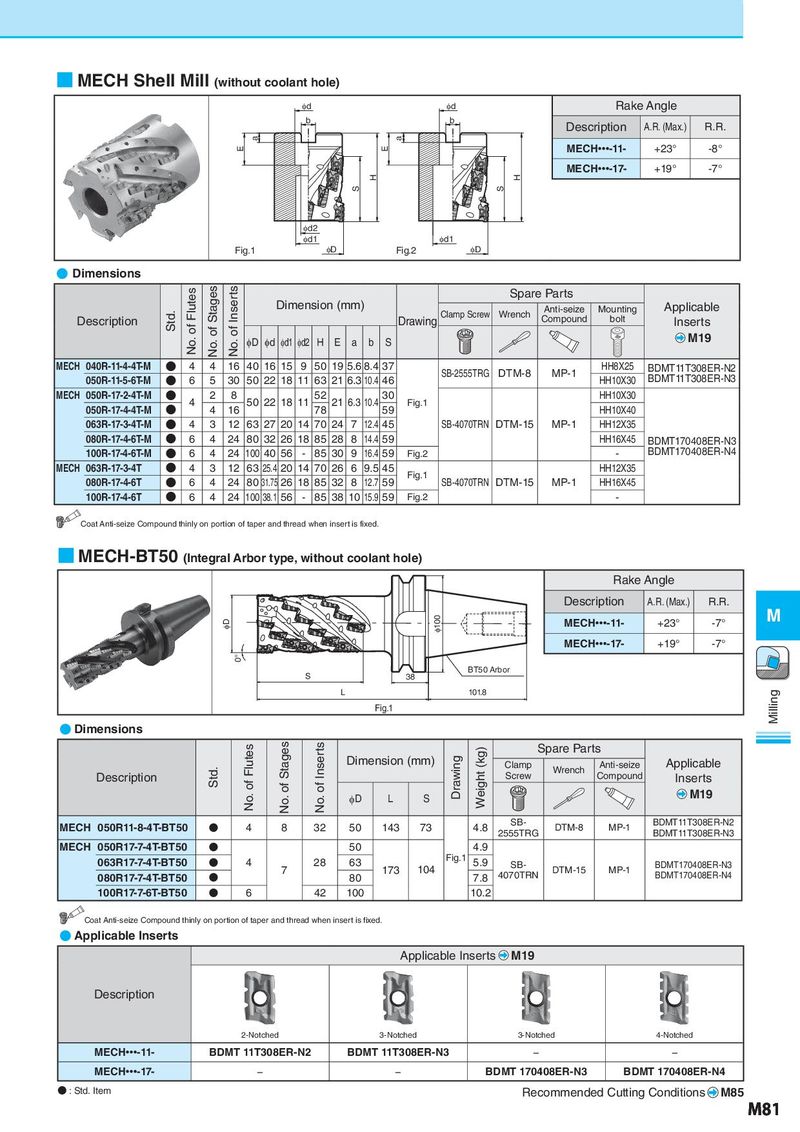

■ MECH Shell Mill (without coolant hole) φd φd Rake Angle b b Description A.R. (Max.) R.R. a a E E MECH● ● ●-11- +23° -8° H H MECH● ● ●-17- +19° -7° S S φd2 φd1 φd1 Fig.1 φD Fig.2 φD ● Dimensions No. of Flutes No. of Stages No. of Inserts Spare Parts Std. Dimension (mm) Clamp Screw Wrench Anti-seize Mounting Applicable Description Drawing Compound bolt Inserts φD φd φd1 φd2 H E a b S M19 MECH 040R-11-4-4T-M N 4 4 16 40 16 15 9 50 19 5.6 8.4 37 SB-2555TRG DTM-8 MP-1 HH8X25 BDMT11T308ER-N2 050R-11-5-6T-M N 6 5 30 50 22 18 11 63 21 6.3 10.4 46 HH10X30 BDMT11T308ER-N3 MECH 050R-17-2-4T-M N 4 2 8 50 22 18 11 52 21 6.3 10.4 30 Fig.1 HH10X30 050R-17-4-4T-M N 4 16 78 59 HH10X40 063R-17-3-4T-M N 4 3 12 63 27 20 14 70 24 7 12.4 45 SB-4070TRN DTM-15 MP-1 HH12X35 080R-17-4-6T-M N 6 4 24 80 32 26 18 85 28 8 14.4 59 HH16X45 BDMT170408ER-N3 100R-17-4-6T-M N 6 4 24 100 40 56 - 85 30 9 16.4 59 Fig.2 - BDMT170408ER-N4 MECH 063R-17-3-4T N 4 3 12 63 25.4 20 14 70 26 6 9.5 45 Fig.1 HH12X35 080R-17-4-6T N 6 4 24 80 31.75 26 18 85 32 8 12.7 59 SB-4070TRN DTM-15 MP-1 HH16X45 100R-17-4-6T N 6 4 24 100 38.1 56 - 85 38 10 15.9 59 Fig.2 - Coat Anti-seize Compound thinly on portion of taper and thread when insert is fixed. ■ MECH-BT50 (Integral Arbor type, without coolant hole) Rake Angle Description A.R. (Max.) R.R. φD φ100 MECH● ● ●-11- +23° -7° M MECH● ● ●-17- +19° -7° 0° S 38 BT50 Arbor L 101.8 Milling Fig.1 ● Dimensions No. of Flutes No. of Stages No. of Inserts Weight (kg) Spare Parts Std. Dimension (mm) Drawing Clamp Wrench Anti-seize Applicable Description Screw Compound Inserts φD L S M19 MECH 050R11-8-4T-BT50 N 4 8 32 50 143 73 4.8 SB- DTM-8 MP-1 BDMT11T308ER-N2 2555TRG BDMT11T308ER-N3 MECH 050R17-7-4T-BT50 N 50 4.9 063R17-7-4T-BT50 N 4 28 63 Fig.1 5.9 SB- BDMT170408ER-N3 080R17-7-4T-BT50 N 7 80 173 104 7.8 4070TRN DTM-15 MP-1 BDMT170408ER-N4 100R17-7-6T-BT50 N 6 42 100 10.2 Coat Anti-seize Compound thinly on portion of taper and thread when insert is fixed. ● Applicable Inserts Applicable Inserts M19 Description 2-Notched 3-Notched 3-Notched 4-Notched MECH● ● ●-11- BDMT 11T308ER-N2 BDMT 11T308ER-N3 − − MECH● ● ●-17- − − BDMT 170408ER-N3 BDMT 170408ER-N4 ● : Std. Item Recommended Cutting Conditions M85 M81