Основной каталог Kyocera 2016-2017 - страница 765

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

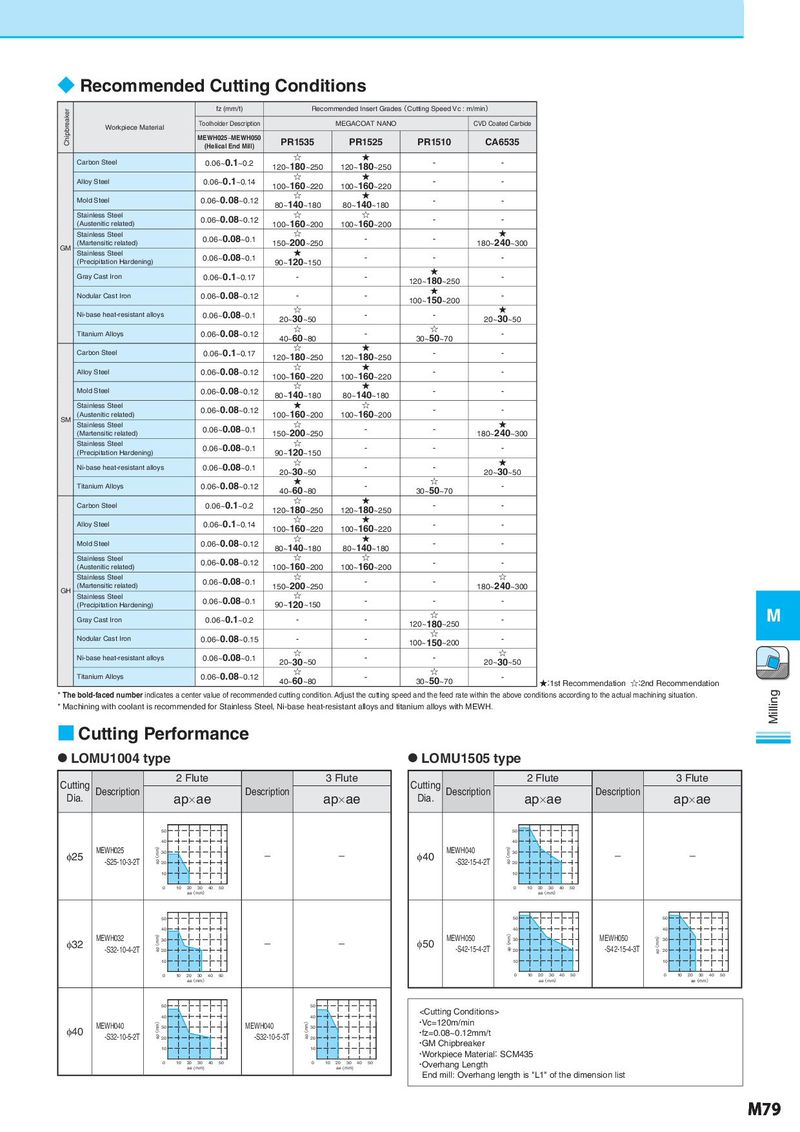

◆ Recommended Cutting Conditions

Chipbreaker fz (mm/t) Recommended Insert Grades(Cutting Speed Vc : m/min)

Workpiece Material Toolholder Description MEGACOAT NANO CVD Coated Carbide

MEWH025~MEWH050 PR1535 PR1525 PR1510 CA6535

(Helical End Mill)

Carbon Steel 0.06~0.1~0.2 ☆ ★ - -

120~180~250 120~180~250

Alloy Steel 0.06~0.1~0.14 ☆ ★ - -

100~160~220 100~160~220

Mold Steel 0.06~0.08~0.12 ☆ ★ - -

80~140~180 80~140~180

Stainless Steel 0.06~0.08~0.12 ☆ ☆ - -

(Austenitic related) 100~160~200 100~160~200

Stainless Steel 0.06~0.08~0.1 ☆ - - ★

GM (Martensitic related) 150~200~250 180~240~300

Stainless Steel 0.06~0.08~0.1 ★ - - -

(Precipitation Hardening) 90~120~150

Gray Cast Iron 0.06~0.1~0.17 - - ★ -

120~180~250

Nodular Cast Iron 0.06~0.08~0.12 - - ★ -

100~150~200

Ni-base heat-resistant alloys 0.06~0.08~0.1 ☆ - - ★

20~30~50 20~30~50

Titanium Alloys 0.06~0.08~0.12 ☆ - ☆ -

40~60~80 30~50~70

Carbon Steel 0.06~0.1~0.17 ☆ ★ - -

120~180~250 120~180~250

Alloy Steel 0.06~0.08~0.12 ☆ ★ - -

100~160~220 100~160~220

Mold Steel 0.06~0.08~0.12 ☆ ★ - -

80~140~180 80~140~180

Stainless Steel 0.06~0.08~0.12 ★ ☆ - -

SM (Austenitic related) 100~160~200 100~160~200

Stainless Steel 0.06~0.08~0.1 ☆ - - ★

(Martensitic related) 150~200~250 180~240~300

Stainless Steel 0.06~0.08~0.1 ☆ - - -

(Precipitation Hardening) 90~120~150

Ni-base heat-resistant alloys 0.06~0.08~0.1 ☆ - - ★

20~30~50 20~30~50

Titanium Alloys 0.06~0.08~0.12 ★ - ☆ -

40~60~80 30~50~70

Carbon Steel 0.06~0.1~0.2 ☆ ★ - -

120~180~250 120~180~250

Alloy Steel 0.06~0.1~0.14 ☆ ★ - -

100~160~220 100~160~220

Mold Steel 0.06~0.08~0.12 ☆ ★ - -

80~140~180 80~140~180

Stainless Steel 0.06~0.08~0.12 ☆ ☆ - -

(Austenitic related) 100~160~200 100~160~200

Stainless Steel 0.06~0.08~0.1 ☆ - - ☆

GH (Martensitic related) 150~200~250 180~240~300

Stainless Steel 0.06~0.08~0.1 ☆ - - -

(Precipitation Hardening) 90~120~150

Gray Cast Iron 0.06~0.1~0.2 - - ☆ - M

120~180~250

Nodular Cast Iron 0.06~0.08~0.15 - - ☆ -

100~150~200

Ni-base heat-resistant alloys 0.06~0.08~0.1 ☆ - - ☆

20~30~50 20~30~50

Titanium Alloys 0.06~0.08~0.12 ☆ - ☆ -

40~60~80 30~50~70 ★:1st Recommendation ☆:2nd Recommendation

* The bold-faced number indicates a center value of recommended cutting condition. Adjust the cutting speed and the feed rate within the above conditions according to the actual machining situation. Milling

* Machining with coolant is recommended for Stainless Steel, Ni-base heat-resistant alloys and titanium alloys with MEWH.

■ Cutting Performance

● LOMU1004 type ● LOMU1505 type

Cutting 2 Flute 3 Flute Cutting 2 Flute 3 Flute

Dia. Description ap×ae Description ap×ae Dia. Description ap×ae Description ap×ae

ap(mm) ap(mm)

50 50

40 40

φ25 MEWH025 ap(mm) 30 - - φ40 MEWH040 ap(mm) 30 - -

-S25-10-3-2T 20 -S32-15-4-2T 20

10 10

0 10 20 30 40 50 0 10 20 30 40 50

ae(mm) ae(mm)

ap(mm) ap(mm) ap(mm)

50 50 50

40 40 40

φ32 MEWH032 ap(mm) 30 - - φ50 MEWH050 ap(mm) 30 MEWH050 ap(mm) 30

-S32-10-4-2T 20 -S42-15-4-2T 20 -S42-15-4-3T 20

10 10 10

0 10 20 30 40 50 0 10 20 30 40 50 0 10 20 30 40 50

ae(mm) ae(mm) ae(mm)

ap(mm) ap(mm)

50 50