Основной каталог Kyocera 2016-2017 - страница 751

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

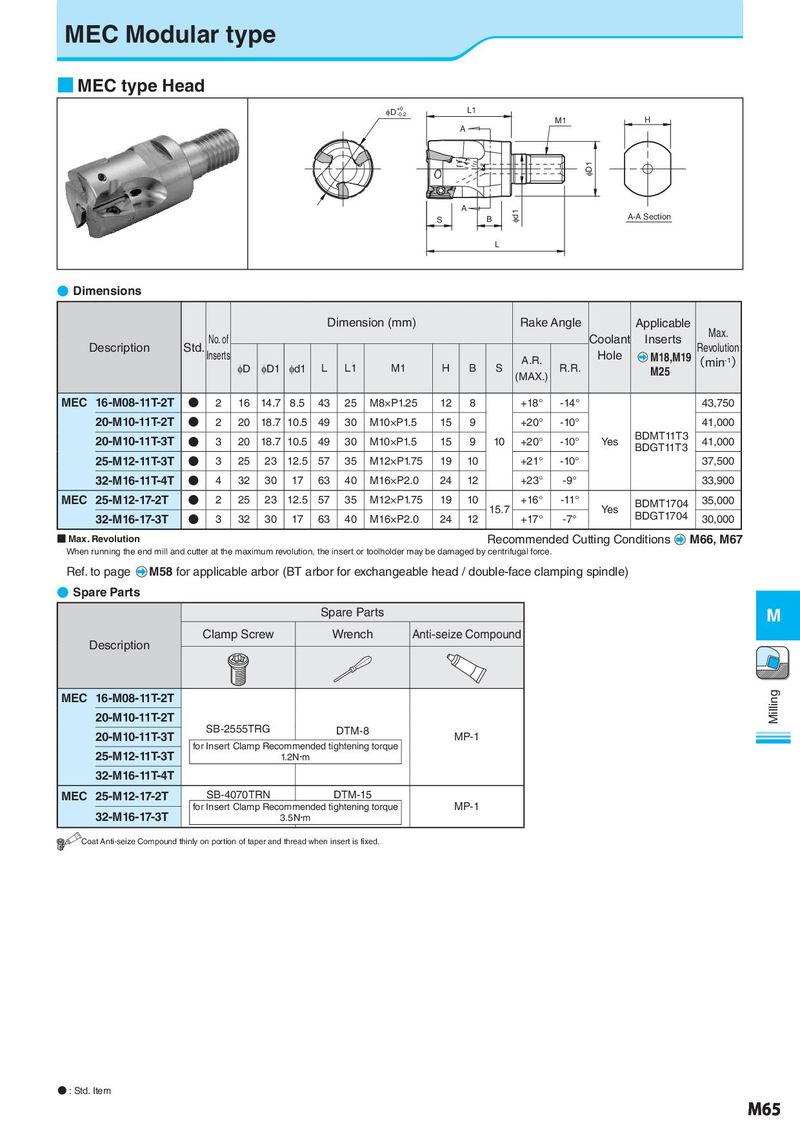

MEC Modular type ■ MEC type Head φD +0 L1 -0.2 H M1 A φD1 A φd1 S B A-A Section L ● Dimensions Dimension (mm) Rake Angle Applicable Max. Description Std. No. of Coolant Inserts Revolution Inserts A.R. Hole M18,M19 (min-1) φD φD1 φd1 L L1 M1 H B S (MAX.) R.R. M25 MEC 16-M08-11T-2T N 2 16 14.7 8.5 43 25 M8×P1.25 12 8 +18° -14° 43,750 20-M10-11T-2T N 2 20 18.7 10.5 49 30 M10×P1.5 15 9 +20° -10° 41,000 20-M10-11T-3T N 3 20 18.7 10.5 49 30 M10×P1.5 15 9 10 +20° -10° Yes BDMT11T3 41,000 BDGT11T3 25-M12-11T-3T N 3 25 23 12.5 57 35 M12×P1.75 19 10 +21° -10° 37,500 32-M16-11T-4T N 4 32 30 17 63 40 M16×P2.0 24 12 +23° -9° 33,900 MEC 25-M12-17-2T N 2 25 23 12.5 57 35 M12×P1.75 19 10 15.7 +16° -11° Yes BDMT1704 35,000 32-M16-17-3T N 3 32 30 17 63 40 M16×P2.0 24 12 +17° -7° BDGT1704 30,000 ■ Max. Revolution Recommended Cutting Conditions M66, M67 When running the end mill and cutter at the maximum revolution, the insert or toolholder may be damaged by centrifugal force. Ref. to page M58 for applicable arbor (BT arbor for exchangeable head / double-face clamping spindle) ● Spare Parts Spare Parts M Clamp Screw Wrench Anti-seize Compound Description MEC 16-M08-11T-2T Milling 20-M10-11T-2T 20-M10-11T-3T SB-2555TRG DTM-8 MP-1 for Insert Clamp Recommended tightening torque 25-M12-11T-3T 1.2N・m 32-M16-11T-4T MEC 25-M12-17-2T SB-4070TRN DTM-15 for Insert Clamp Recommended tightening torque MP-1 32-M16-17-3T 3.5N・m Coat Anti-seize Compound thinly on portion of taper and thread when insert is fixed. ● : Std. Item M65