Основной каталог Kyocera 2016-2017 - страница 736

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

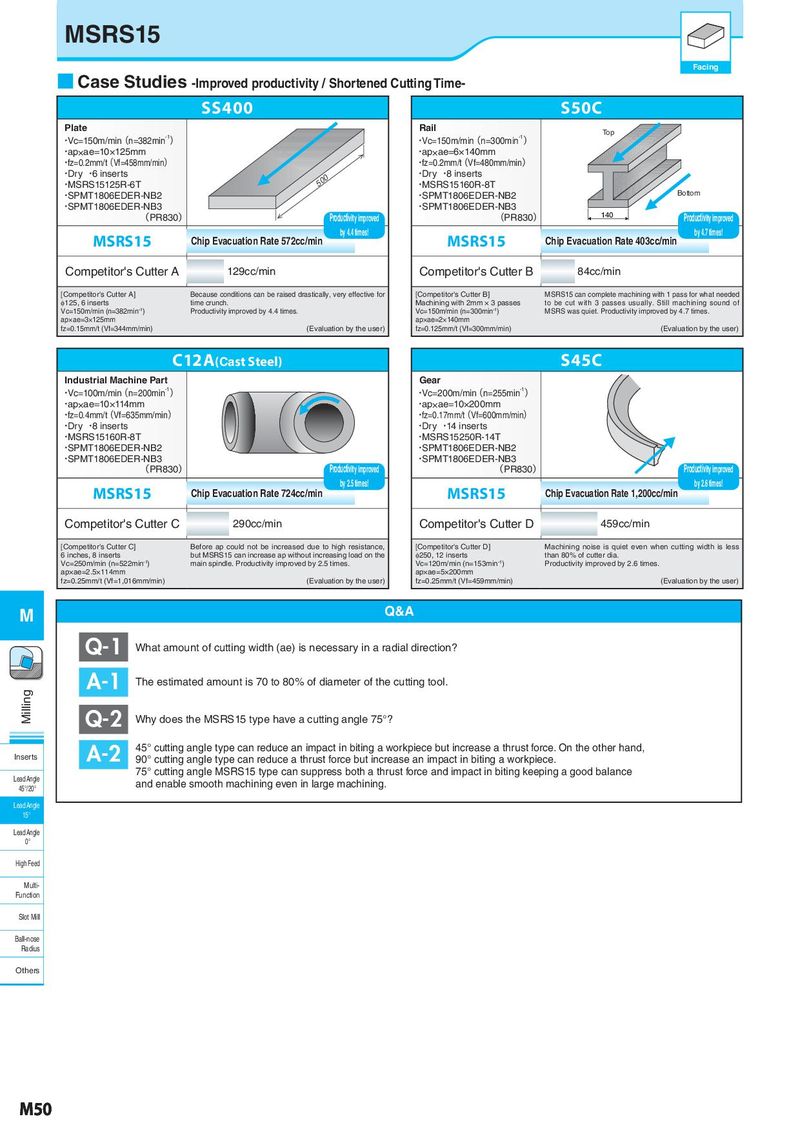

MSRS15 Facing ■ Case Studies -Improved productivity / Shortened Cutting Time- SS400 S50C Plate Rail Top ・Vc=150m/min(n=382min-1) ・Vc=150m/min(n=300min-1) ・ap×ae=10×125mm ・ap×ae=6×140mm ・fz=0.2mm/t(Vf=458mm/min) ・fz=0.2mm/t(Vf=480mm/min) ・Dry ・6 inserts 500 ・Dry ・8 inserts ・MSRS15125R-6T ・MSRS15160R-8T ・SPMT1806EDER-NB2 ・SPMT1806EDER-NB2 Bottom ・SPMT1806EDER-NB3 ・SPMT1806EDER-NB3 (PR830) Productivity improved (PR830) 140 Productivity improved MSRS15 Chip Evacuation Rate 572cc/min by 4.4 times! MSRS15 Chip Evacuation Rate 403cc/min by 4.7 times! Competitor's Cutter A 129cc/min Competitor's Cutter B 84cc/min [Competitor's Cutter A] Because conditions can be raised drastically, very effective for [Competitor's Cutter B] MSRS15 can complete machining with 1 pass for what needed φ125, 6 inserts time crunch. Machining with 2mm × 3 passes to be cut with 3 passes usually. Still machining sound of Vc=150m/min (n=382min-1) Productivity improved by 4.4 times. Vc=150m/min (n=300min-1) MSRS was quiet. Productivity improved by 4.7 times. ap×ae=3×125mm ap×ae=2×140mm fz=0.15mm/t (Vf=344mm/min) (Evaluation by the user) fz=0.125mm/t (Vf=300mm/min) (Evaluation by the user) C12A(Cast Steel) S45C Industrial Machine Part Gear ・Vc=100m/min(n=200min-1) ・Vc=200m/min(n=255min-1) ・ap×ae=10×114mm ・ap×ae=10×200mm ・fz=0.4mm/t(Vf=635mm/min) ・fz=0.17mm/t(Vf=600mm/min) ・Dry ・8 inserts ・Dry ・14 inserts ・MSRS15160R-8T ・MSRS15250R-14T ・SPMT1806EDER-NB2 ・SPMT1806EDER-NB2 ・SPMT1806EDER-NB3 ・SPMT1806EDER-NB3 (PR830) Productivity improved (PR830) Productivity improved MSRS15 by 2.5 times! MSRS15 by 2.6 times! Chip Evacuation Rate 724cc/min Chip Evacuation Rate 1,200cc/min Competitor's Cutter C 290cc/min Competitor's Cutter D 459cc/min [Competitor's Cutter C] Before ap could not be increased due to high resistance, [Competitor's Cutter D] Machining noise is quiet even when cutting width is less 6 inches, 8 inserts but MSRS15 can increase ap without increasing load on the φ250, 12 inserts than 80% of cutter dia. Vc=250m/min (n=522min-1) main spindle. Productivity improved by 2.5 times. Vc=120m/min (n=153min-1) Productivity improved by 2.6 times. ap×ae=2.5×114mm ap×ae=5×200mm fz=0.25mm/t (Vf=1,016mm/min) (Evaluation by the user) fz=0.25mm/t (Vf=459mm/min) (Evaluation by the user) M Q&A Q-1 What amount of cutting width (ae) is necessary in a radial direction? A-1 The estimated amount is 70 to 80% of diameter of the cutting tool. Milling Q-2 Why does the MSRS15 type have a cutting angle 75°? A-2 45° cutting angle type can reduce an impact in biting a workpiece but increase a thrust force. On the other hand, Inserts 90° cutting angle type can reduce a thrust force but increase an impact in biting a workpiece. Lead Angle 75° cutting angle MSRS15 type can suppress both a thrust force and impact in biting keeping a good balance 45°/20° and enable smooth machining even in large machining. Lead Angle 15° Lead Angle 0° High Feed Multi- Function Slot Mill Ball-nose Radius Others M50