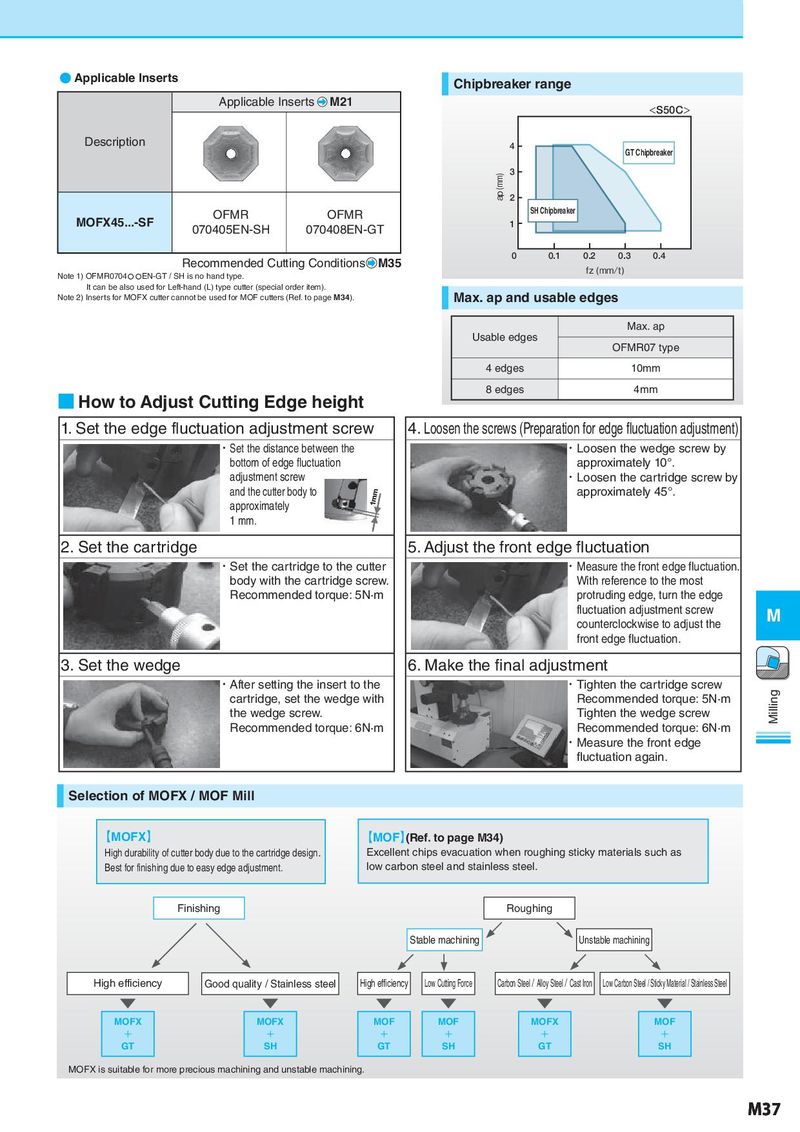

● Applicable Inserts Chipbreaker range

Applicable Inserts M21

Description 4

GT Chipbreaker

ap (mm) 3

2

OFMR OFMR SH Chipbreaker

MOFX45...-SF 070405EN-SH 070408EN-GT 1

Recommended Cutting Conditions M35 0 0.1 0.2 0.3 0.4

Note 1) OFMR0704¡¡EN-GT / SH is no hand type. fz (mm/t)

It can be also used for Left-hand (L) type cutter (special order item).

Note 2) Inserts for MOFX cutter cannot be used for MOF cutters (Ref. to page M34). Max. ap and usable edges

Max. ap

Usable edges

OFMR07 type

4 edges 10mm

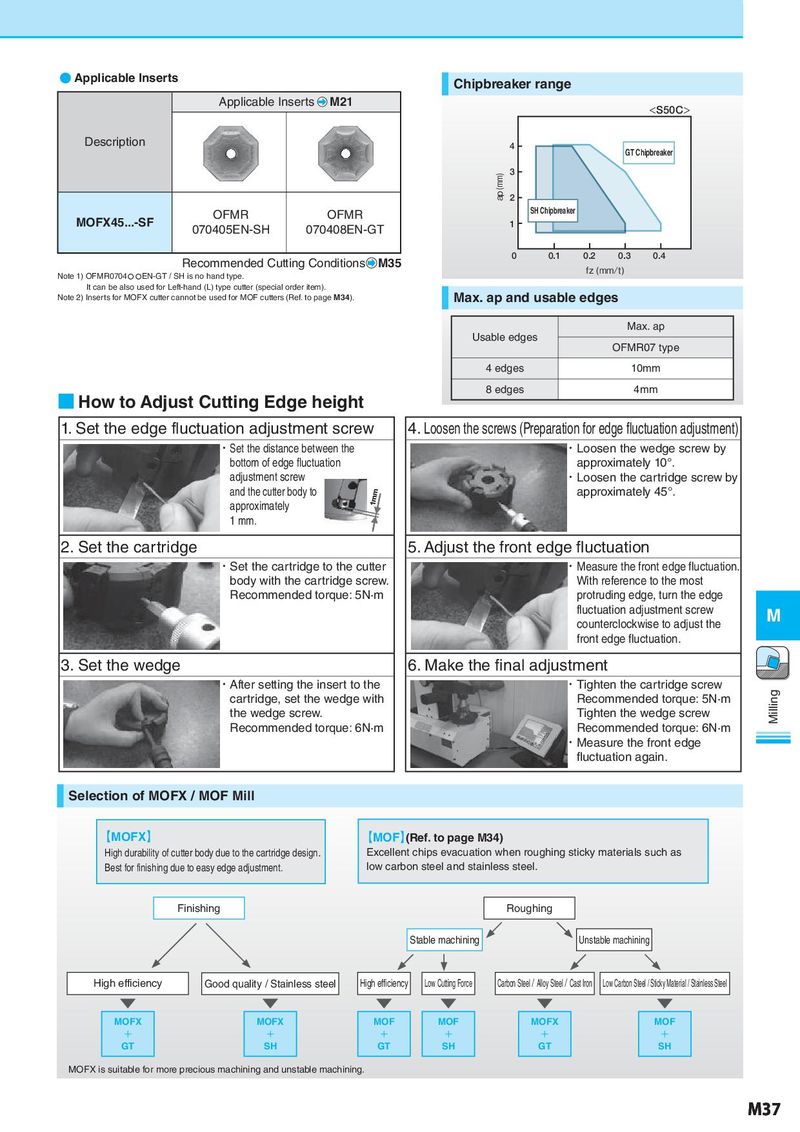

■ How to Adjust Cutting Edge height 8 edges 4mm

1. Set the edge fluctuation adjustment screw 4. Loosen the screws (Preparation for edge fluctuation adjustment)

・Set the distance between the ・Loosen the wedge screw by

bottom of edge fluctuation approximately 10°.

adjustment screw ・Loosen the cartridge screw by

and the cutter body to �PP approximately 45°.

approximately

1 mm.

2. Set the cartridge 5. Adjust the front edge fluctuation

・Set the cartridge to the cutter ・Measure the front edge fluctuation.

body with the cartridge screw. With reference to the most

Recommended torque: 5N·m protruding edge, turn the edge

fluctuation adjustment screw M

counterclockwise to adjust the

front edge fluctuation.

3. Set the wedge 6. Make the final adjustment

・After setting the insert to the ・Tighten the cartridge screw Milling

cartridge, set the wedge with Recommended torque: 5N·m

the wedge screw. Tighten the wedge screw

Recommended torque: 6N·m Recommended torque: 6N·m

・Measure the front edge

fluctuation again.

Selection of MOFX / MOF Mill

【MOFX】 【MOF】(Ref. to page M34)

High durability of cutter body due to the cartridge design. Excellent chips evacuation when roughing sticky materials such as

Best for finishing due to easy edge adjustment. low carbon steel and stainless steel.

Finishing Roughing

Stable machining Unstable machining

High efficiency Good quality / Stainless steel High efficiency Low Cutting Force Carbon Steel / Alloy Steel / Cast Iron Low Carbon Steel / Sticky Material / Stainless Steel

MOFX MOFX MOF MOF MOFX MOF

+ + + + + +

GT SH GT SH GT SH

MOFX is suitable for more precious machining and unstable machining.

M37

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA