Основной каталог Kyocera 2016-2017 - страница 721

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

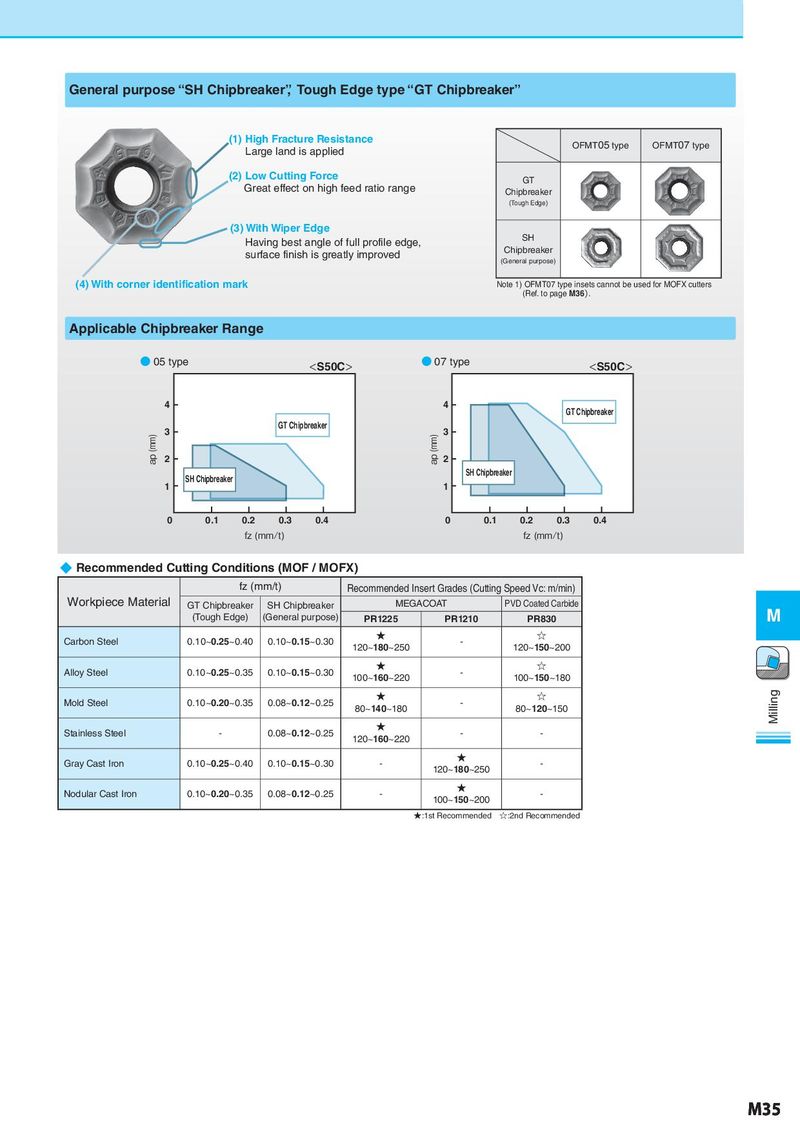

General purpose “SH Chipbreaker”, Tough Edge type “GT Chipbreaker”

(1) High Fracture Resistance OFMT05 type OFMT07 type

Large land is applied

(2) Low Cutting Force GT

Great effect on high feed ratio range Chipbreaker

(Tough Edge)

(3) With Wiper Edge

Having best angle of full profile edge, SH

surface finish is greatly improved Chipbreaker

(General purpose)

(4) With corner identification mark Note 1) OFMT07 type insets cannot be used for MOFX cutters

(Ref. to page M36).

Applicable Chipbreaker Range

● 05 type