Основной каталог Kyocera 2016-2017 - страница 717

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

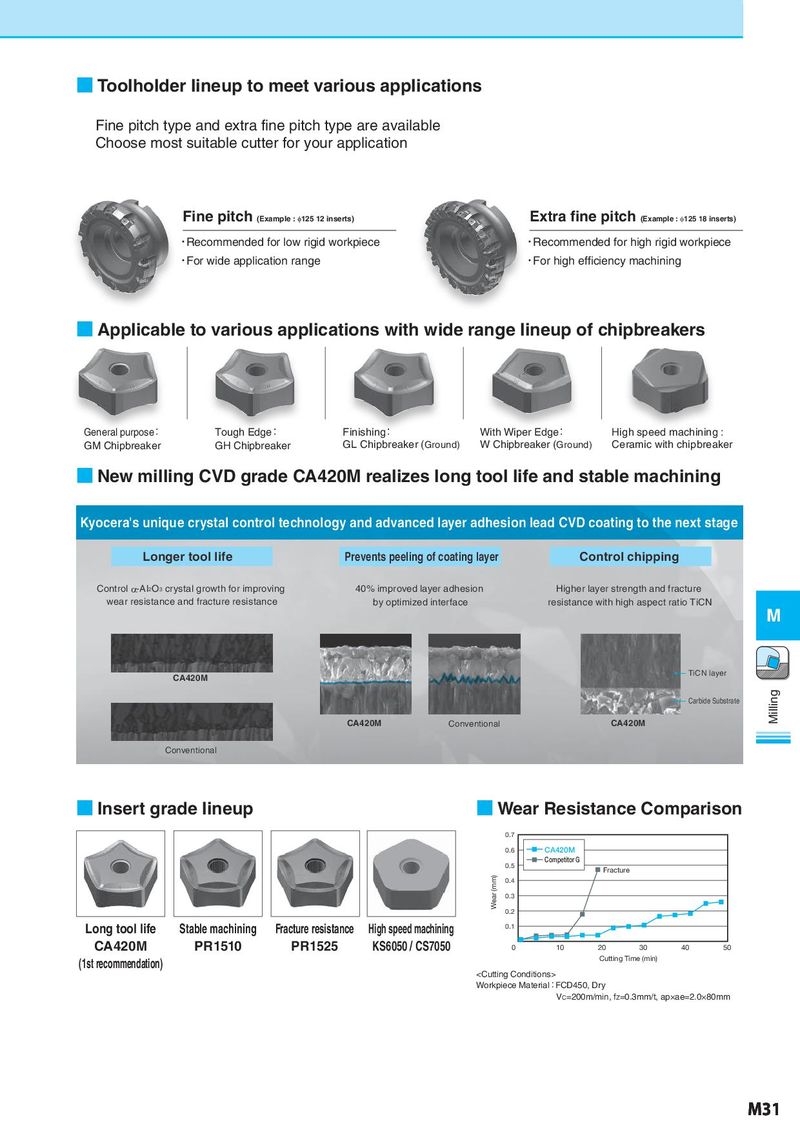

■ Toolholder lineup to meet various applications

Fine pitch type and extra fine pitch type are available

Choose most suitable cutter for your application

Fine pitch (Example : φ125 12 inserts) Extra fine pitch (Example : φ125 18 inserts)

・Recommended for low rigid workpiece ・Recommended for high rigid workpiece

・For wide application range ・For high efficiency machining

■ Applicable to various applications with wide range lineup of chipbreakers

General purpose: Tough Edge: Finishing: With Wiper Edge: High speed machining :

GM Chipbreaker GH Chipbreaker GL Chipbreaker (Ground) W Chipbreaker (Ground) Ceramic with chipbreaker

■ New milling CVD grade CA420M realizes long tool life and stable machining

Kyocera's unique crystal control technology and advanced layer adhesion lead CVD coating to the next stage

Longer tool life Prevents peeling of coating layer Control chipping

Control α-Al2O3 crystal growth for improving 40% improved layer adhesion Higher layer strength and fracture

wear resistance and fracture resistance by optimized interface resistance with high aspect ratio TiCN

M

CA420M TiCN layer

Carbide Substrate Milling

CA420M Conventional CA420M

Conventional

■ Insert grade lineup ■ Wear Resistance Comparison

0.7

0.6 CA420M

0.5 Competitor G

Fracture

Wear (mm) 0.4

0.3

0.2

Long tool life Stable machining Fracture resistance High speed machining 0.1

CA420M PR1510 PR1525 KS6050 / CS7050 0 10 20 30 40 50

(1st recommendation) Cutting Time (min)