Основной каталог Kyocera 2016-2017 - страница 716

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

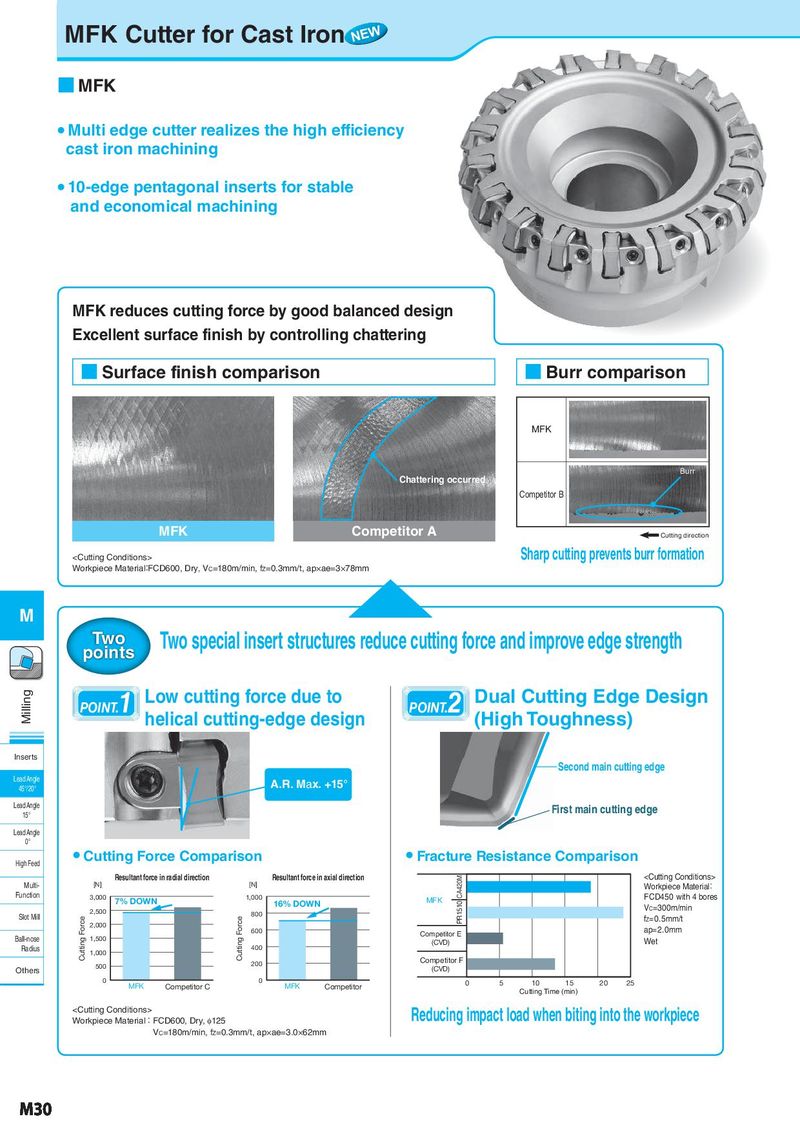

MFK Cutter for Cast Iron NEW

■ MFK

● Multi edge cutter realizes the high efficiency

cast iron machining

● 10-edge pentagonal inserts for stable

and economical machining

MFK reduces cutting force by good balanced design

Excellent surface finish by controlling chattering

■ Surface finish comparison ■ Burr comparison

MFK

Burr

Chattering occurred

Competitor B

MFK Competitor A Cutting direction