Основной каталог Kyocera 2016-2017 - страница 714

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

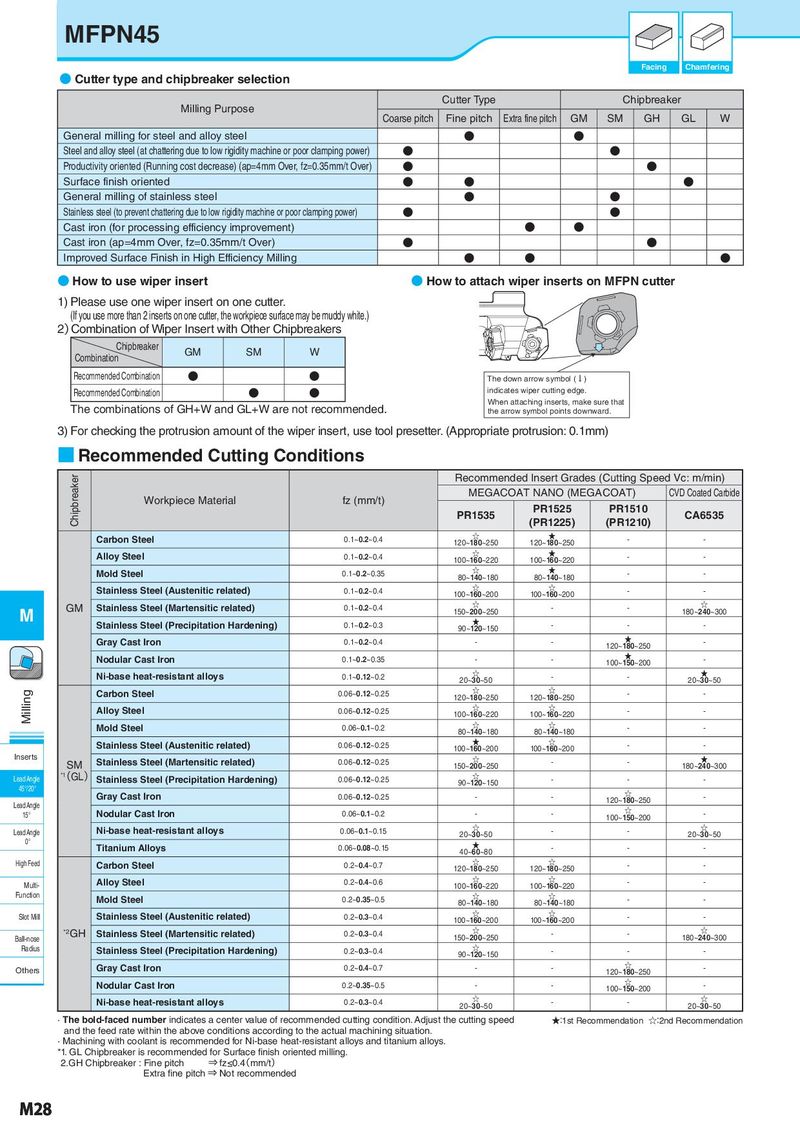

MFPN45 Facing Chamfering ● Cutter type and chipbreaker selection Milling Purpose Cutter Type Chipbreaker Coarse pitch Fine pitch Extra fine pitch GM SM GH GL W General milling for steel and alloy steel ● ● Steel and alloy steel (at chattering due to low rigidity machine or poor clamping power) ● ● Productivity oriented (Running cost decrease) (ap=4mm Over, fz=0.35mm/t Over) ● ● Surface finish oriented ● ● ● General milling of stainless steel ● ● Stainless steel (to prevent chattering due to low rigidity machine or poor clamping power) ● ● Cast iron (for processing efficiency improvement) ● ● Cast iron (ap=4mm Over, fz=0.35mm/t Over) ● ● Improved Surface Finish in High Efficiency Milling ● ● ● ● How to use wiper insert ● How to attach wiper inserts on MFPN cutter 1) Please use one wiper insert on one cutter. (If you use more than 2 inserts on one cutter, the workpiece surface may be muddy white.) 2)Combination of Wiper Insert with Other Chipbreakers Chipbreaker GM SM W Combination Recommended Combination ● ● The down arrow symbol (↓) Recommended Combination ● ● indicates wiper cutting edge. The combinations of GH+W and GL+W are not recommended. When attaching inserts, make sure that the arrow symbol points downward. 3) For checking the protrusion amount of the wiper insert, use tool presetter. (Appropriate protrusion: 0.1mm) ■ Recommended Cutting Conditions Chipbreaker Recommended Insert Grades (Cutting Speed Vc: m/min) Workpiece Material fz (mm/t) MEGACOAT NANO (MEGACOAT) CVD Coated Carbide PR1535 PR1525 PR1510 CA6535 (PR1225) (PR1210) Carbon Steel 0.1~0.2~0.4 ☆ ★ - - 120~180~250 120~180~250 Alloy Steel 0.1~0.2~0.4 ☆ ★ - - 100~160~220 100~160~220 Mold Steel 0.1~0.2~0.35 ☆ ★ - - 80~140~180 80~140~180 Stainless Steel (Austenitic related) 0.1~0.2~0.4 ☆ ☆ - - 100~160~200 100~160~200 GM Stainless Steel (Martensitic related) 0.1~0.2~0.4 ☆ - - ☆ M 150~200~250 180~240~300 Stainless Steel (Precipitation Hardening) 0.1~0.2~0.3 ★ - - - 90~120~150 Gray Cast Iron 0.1~0.2~0.4 - - ★ - 120~180~250 Nodular Cast Iron 0.1~0.2~0.35 - - ★ - 100~150~200 Ni-base heat-resistant alloys 0.1~0.12~0.2 ☆ - - ★ 20~30~50 20~30~50 Milling Carbon Steel 0.06~0.12~0.25 ☆ ☆ - - 120~180~250 120~180~250 Alloy Steel 0.06~0.12~0.25 ☆ ☆ - - 100~160~220 100~160~220 Mold Steel 0.06~0.1~0.2 ☆ ☆ - - 80~140~180 80~140~180 Stainless Steel (Austenitic related) 0.06~0.12~0.25 ★ ☆ - - 100~160~200 100~160~200 Inserts SM Stainless Steel (Martensitic related) 0.06~0.12~0.25 ☆ - - ★ 150~200~250 180~240~300 Lead Angle *(1 GL) Stainless Steel (Precipitation Hardening) 0.06~0.12~0.25 ☆ - - - 90~120~150 45°/20° ☆ Gray Cast Iron 0.06~0.12~0.25 - - 120~180~250 - Lead Angle ☆ 15° Nodular Cast Iron 0.06~0.1~0.2 - - 100~150~200 - Lead Angle Ni-base heat-resistant alloys 0.06~0.1~0.15 ☆ - - ☆ 20~30~50 20~30~50 0° Titanium Alloys 0.06~0.08~0.15 ★ - - - 40~60~80 High Feed Carbon Steel 0.2~0.4~0.7 ☆ ☆ - - 120~180~250 120~180~250 Multi- Alloy Steel 0.2~0.4~0.6 ☆ ☆ - - 100~160~220 100~160~220 Function Mold Steel 0.2~0.35~0.5 ☆ ☆ - - 80~140~180 80~140~180 Slot Mill Stainless Steel (Austenitic related) 0.2~0.3~0.4 ☆ ☆ - - 100~160~200 100~160~200 *2 GH Stainless Steel (Martensitic related) 0.2~0.3~0.4 ☆ - - ☆ 150~200~250 180~240~300 Ball-nose Radius Stainless Steel (Precipitation Hardening) 0.2~0.3~0.4 ☆ - - - 90~120~150 Others Gray Cast Iron 0.2~0.4~0.7 - - ☆ - 120~180~250 Nodular Cast Iron 0.2~0.35~0.5 - - ☆ - 100~150~200 Ni-base heat-resistant alloys 0.2~0.3~0.4 ☆ - - ☆ 20~30~50 20~30~50 · The bold-faced number indicates a center value of recommended cutting condition. Adjust the cutting speed ★:1st Recommendation ☆:2nd Recommendation and the feed rate within the above conditions according to the actual machining situation. · Machining with coolant is recommended for Ni-base heat-resistant alloys and titanium alloys. *1. GL Chipbreaker is recommended for Surface finish oriented milling. 2.GH Chipbreaker : Fine pitch ⇒ fz≤0.4(mm/t) Extra fine pitch ⇒ Not recommended M28