Основной каталог Kyocera 2016-2017 - страница 680

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

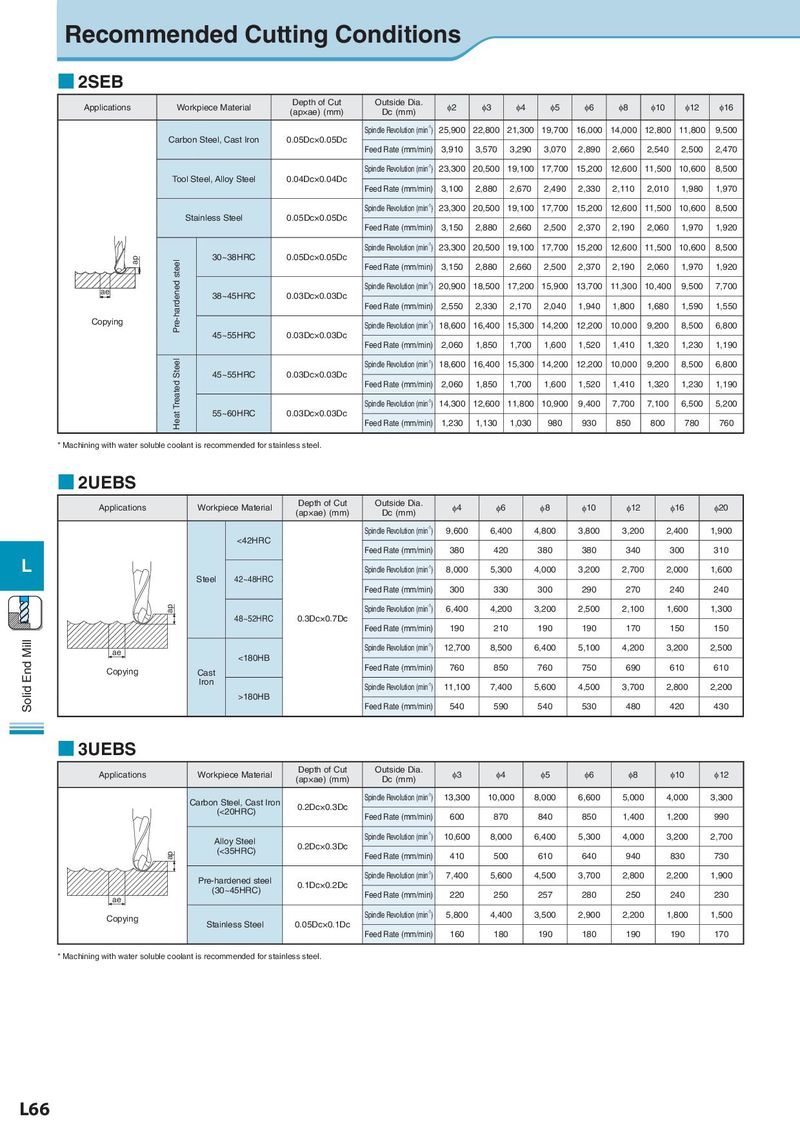

Recommended Cutting Conditions ■ 2SEB Applications Workpiece Material Depth of Cut Outside Dia. φ2 φ3 φ4 φ5 φ6 φ8 φ10 φ12 φ16 (ap×ae) (mm) Dc (mm) Spindle Revolution (min-1) 25,900 22,800 21,300 19,700 16,000 14,000 12,800 11,800 9,500 Carbon Steel, Cast Iron 0.05Dc×0.05Dc Feed Rate (mm/min) 3,910 3,570 3,290 3,070 2,890 2,660 2,540 2,500 2,470 Spindle Revolution (min-1) 23,300 20,500 19,100 17,700 15,200 12,600 11,500 10,600 8,500 Tool Steel, Alloy Steel 0.04Dc×0.04Dc Feed Rate (mm/min) 3,100 2,880 2,670 2,490 2,330 2,110 2,010 1,980 1,970 Spindle Revolution (min-1) 23,300 20,500 19,100 17,700 15,200 12,600 11,500 10,600 8,500 Stainless Steel 0.05Dc×0.05Dc Feed Rate (mm/min) 3,150 2,880 2,660 2,500 2,370 2,190 2,060 1,970 1,920 Spindle Revolution (min-1) 23,300 20,500 19,100 17,700 15,200 12,600 11,500 10,600 8,500 ap Pre-hardened steel 30~38HRC 0.05Dc×0.05Dc Feed Rate (mm/min) 3,150 2,880 2,660 2,500 2,370 2,190 2,060 1,970 1,920 ae Spindle Revolution (min-1) 20,900 18,500 17,200 15,900 13,700 11,300 10,400 9,500 7,700 38~45HRC 0.03Dc×0.03Dc Feed Rate (mm/min) 2,550 2,330 2,170 2,040 1,940 1,800 1,680 1,590 1,550 Copying Spindle Revolution (min-1) 18,600 16,400 15,300 14,200 12,200 10,000 9,200 8,500 6,800 45~55HRC 0.03Dc×0.03Dc Feed Rate (mm/min) 2,060 1,850 1,700 1,600 1,520 1,410 1,320 1,230 1,190 Heat Treated Steel Spindle Revolution (min-1) 18,600 16,400 15,300 14,200 12,200 10,000 9,200 8,500 6,800 45~55HRC 0.03Dc×0.03Dc Feed Rate (mm/min) 2,060 1,850 1,700 1,600 1,520 1,410 1,320 1,230 1,190 Spindle Revolution (min-1) 14,300 12,600 11,800 10,900 9,400 7,700 7,100 6,500 5,200 55~60HRC 0.03Dc×0.03Dc Feed Rate (mm/min) 1,230 1,130 1,030 980 930 850 800 780 760 * Machining with water soluble coolant is recommended for stainless steel. ■ 2UEBS Applications Workpiece Material Depth of Cut Outside Dia. φ4 φ6 φ8 φ10 φ12 φ16 φ20 (ap×ae) (mm) Dc (mm) Spindle Revolution (min-1) 9,600 6,400 4,800 3,800 3,200 2,400 1,900 <42HRC Feed Rate (mm/min) 380 420 380 380 340 300 310 L Spindle Revolution (min-1) 8,000 5,300 4,000 3,200 2,700 2,000 1,600 Steel 42~48HRC Feed Rate (mm/min) 300 330 300 290 270 240 240 ap Spindle Revolution (min-1) 6,400 4,200 3,200 2,500 2,100 1,600 1,300 48~52HRC 0.3Dc×0.7Dc Feed Rate (mm/min) 190 210 190 190 170 150 150 Solid End Mill ae Spindle Revolution (min-1) 12,700 8,500 6,400 5,100 4,200 3,200 2,500 <180HB Copying Cast Feed Rate (mm/min) 760 850 760 750 690 610 610 Iron Spindle Revolution (min-1) 11,100 7,400 5,600 4,500 3,700 2,800 2,200 >180HB Feed Rate (mm/min) 540 590 540 530 480 420 430 ■ 3UEBS Applications Workpiece Material Depth of Cut Outside Dia. φ3 φ4 φ5 φ6 φ8 φ10 φ12 (ap×ae) (mm) Dc (mm) Carbon Steel, Cast Iron Spindle Revolution (min-1) 13,300 10,000 8,000 6,600 5,000 4,000 3,300 (<20HRC) 0.2Dc×0.3Dc Feed Rate (mm/min) 600 870 840 850 1,400 1,200 990 Alloy Steel Spindle Revolution (min-1) 10,600 8,000 6,400 5,300 4,000 3,200 2,700 (<35HRC) 0.2Dc×0.3Dc ap Feed Rate (mm/min) 410 500 610 640 940 830 730 Pre-hardened steel Spindle Revolution (min-1) 7,400 5,600 4,500 3,700 2,800 2,200 1,900 (30~45HRC) 0.1Dc×0.2Dc ae Feed Rate (mm/min) 220 250 257 280 250 240 230 Copying Spindle Revolution (min-1) 5,800 4,400 3,500 2,900 2,200 1,800 1,500 Stainless Steel 0.05Dc×0.1Dc Feed Rate (mm/min) 160 180 190 180 190 190 170 * Machining with water soluble coolant is recommended for stainless steel. L66