Основной каталог Kyocera 2016-2017 - страница 648

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

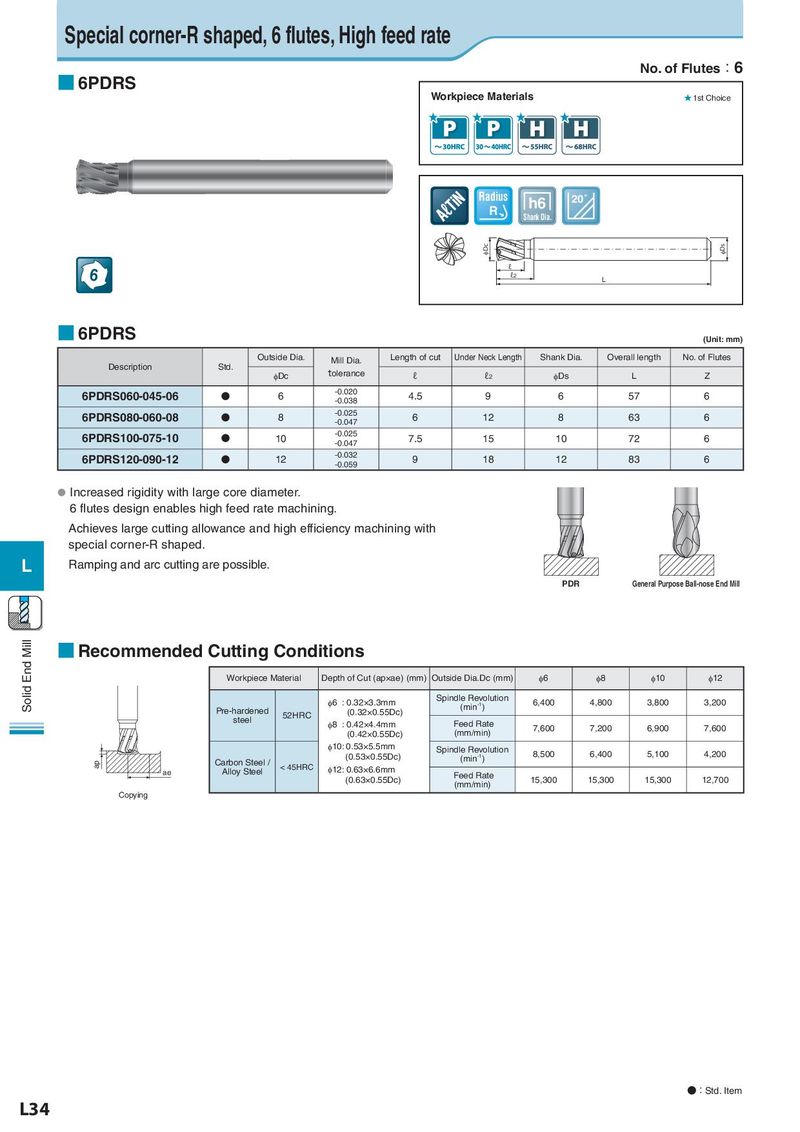

Special corner-R shaped, 6 flutes, High feed rate ■ 6PDRS No. of Flutes:6 Workpiece Materials ★ 1st Choice Radius h6 20˚ R Shank Dia. φDc φDs 6 ℓ ℓ2 L ■ 6PDRS (Unit: mm) Outside Dia. Mill Dia. Length of cut Under Neck Length Shank Dia. Overall length No. of Flutes Description Std. tolerance φDc ℓ ℓ2 φDs L Z 6PDRS060-045-06 N 6 -0.020 4.5 9 6 57 6 -0.038 6PDRS080-060-08 N 8 -0.025 6 12 8 63 6 -0.047 6PDRS100-075-10 N 10 -0.025 7.5 15 10 72 6 -0.047 6PDRS120-090-12 N 12 -0.032 9 18 12 83 6 -0.059 ● Increased rigidity with large core diameter. 6 flutes design enables high feed rate machining. Achieves large cutting allowance and high efficiency machining with special corner-R shaped. L Ramping and arc cutting are possible. PDR General Purpose Ball-nose End Mill Solid End Mill ■ Recommended Cutting Conditions Workpiece Material Depth of Cut (ap×ae) (mm) Outside Dia.Dc (mm) φ6 φ8 φ10 φ12 φ6 :0.32×3.3mm Spindle Revolution 6,400 4,800 3,800 3,200 Pre-hardened (0.32×0.55Dc) (min-1) steel 52HRC φ8 :0.42×4.4mm Feed Rate 7,600 7,200 6,900 7,600 (0.42×0.55Dc) (mm/min) φ10:0.53×5.5mm Spindle Revolution 8,500 6,400 5,100 4,200 ap Carbon Steel / (0.53×0.55Dc) (min-1) ae Alloy Steel < 45HRC φ12:0.63×6.6mm (0.63×0.55Dc) Feed Rate 15,300 15,300 15,300 12,700 (mm/min) Copying ●:Std. Item L34