Основной каталог Kyocera 2016-2017 - страница 637

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

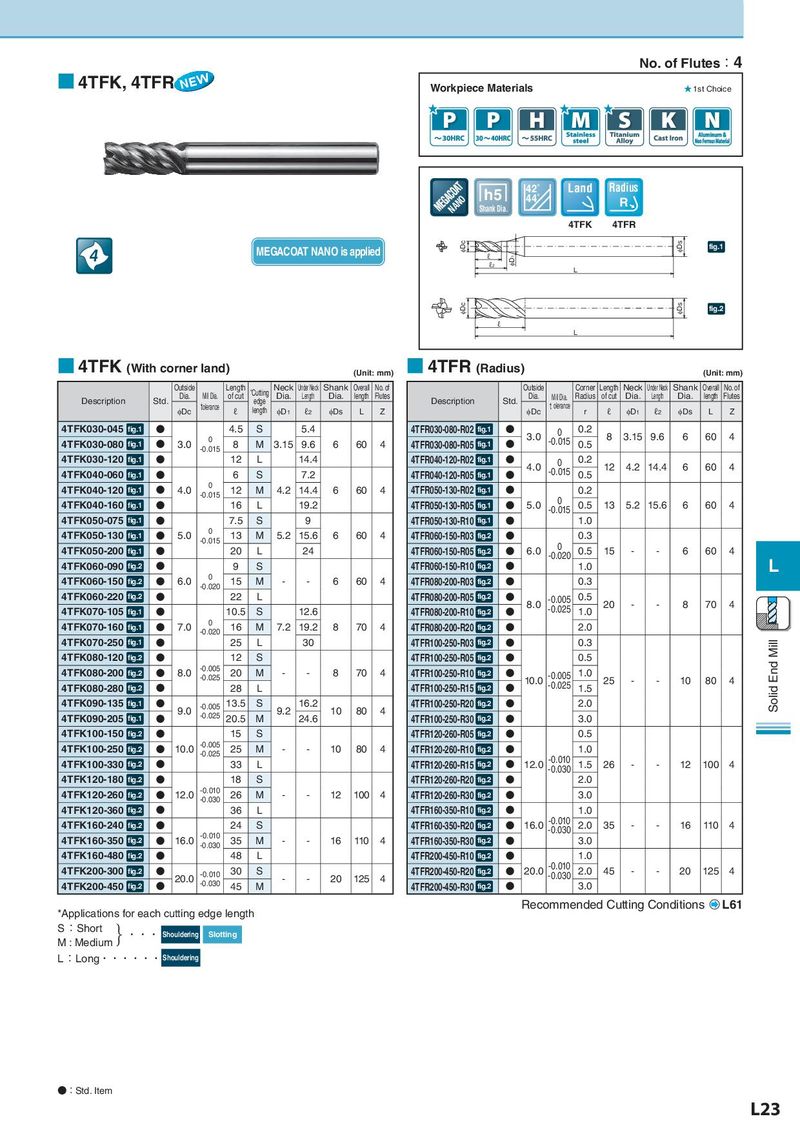

No. of Flutes:4 ■ 4TFK, 4TFR 1(: Workpiece Materials ★ 1st Choice h5 42˚ Land Radius 44˚ NANO R Shank Dia. 4TFK 4TFR 4 MEGACOAT NANO is applied φDc φDs fig.1 ℓ φD1 ℓ2 L φDc φDs fig.2 ℓ L ■ 4TFK (With corner land) (Unit: mm) ■ 4TFR (Radius) (Unit: mm) Outside Length *Cutting Neck Under Neck Shank Overall No. of Outside Corner Length Neck Under Neck Shank Overall No. of Description Std. Dia. Mill Dia. of cut edge Dia. Length Dia. length Flutes Description Std. Dia. Mill Dia. Radius of cut Dia. Length Dia. length Flutes φDc tolerance ℓ length φD1 ℓ2 φDs L Z φDc tolerance r ℓ φD1 ℓ2 φDs L Z 4TFK030-045 fig.1 N 4.5 S 5.4 4TFR030-080-R02 fig.1 N 0 0.2 4TFK030-080 fig.1 N 3.0 0 8 M 3.15 9.6 6 60 4 4TFR030-080-R05 fig.1 N 3.0 -0.015 0.5 8 3.15 9.6 6 60 4 -0.015 4TFK030-120 fig.1 N 12 L 14.4 4TFR040-120-R02 fig.1 N 4.0 0 0.2 12 4.2 14.4 6 60 4 4TFK040-060 fig.1 N 6 S 7.2 4TFR040-120-R05 fig.1 N -0.015 0.5 4TFK040-120 fig.1 N 4.0 0 12 M 4.2 14.4 6 60 4 4TFR050-130-R02 fig.1 N 0.2 -0.015 0 4TFK040-160 fig.1 N 16 L 19.2 4TFR050-130-R05 fig.1 N 5.0 -0.015 0.5 13 5.2 15.6 6 60 4 4TFK050-075 fig.1 N 7.5 S 9 4TFR050-130-R10 fig.1 N 1.0 4TFK050-130 fig.1 N 5.0 0 13 M 5.2 15.6 6 60 4 4TFR060-150-R03 fig.2 N 0.3 -0.015 0 4TFK050-200 fig.1 N 20 L 24 4TFR060-150-R05 fig.2 N 6.0 -0.020 0.5 15 - - 6 60 4 4TFK060-090 fig.2 N 9 S 4TFR060-150-R10 fig.2 N 1.0 L 4TFK060-150 fig.2 N 6.0 0 15 M - - 6 60 4 4TFR080-200-R03 fig.2 N 0.3 -0.020 4TFK060-220 fig.2 N 22 L 4TFR080-200-R05 fig.2 N 8.0 -0.005 0.5 20 - - 8 70 4 4TFK070-105 fig.1 N 10.5 S 12.6 4TFR080-200-R10 fig.2 N -0.025 1.0 4TFK070-160 fig.1 N 7.0 0 16 M 7.2 19.2 8 70 4 4TFR080-200-R20 fig.2 N 2.0 -0.020 4TFK070-250 fig.1 N 25 L 30 4TFR100-250-R03 fig.2 N 0.3 Solid End Mill 4TFK080-120 fig.2 N 12 S 4TFR100-250-R05 fig.2 N 0.5 4TFK080-200 fig.2 N 8.0 -0.005 20 M - - 8 70 4 4TFR100-250-R10 fig.2 N -0.005 1.0 -0.025 10.0 -0.025 25 - - 10 80 4 4TFK080-280 fig.2 N 28 L 4TFR100-250-R15 fig.2 N 1.5 4TFK090-135 fig.1 N 9.0 -0.005 13.5 S 9.2 16.2 10 80 4 4TFR100-250-R20 fig.2 N 2.0 4TFK090-205 fig.1 N -0.025 20.5 M 24.6 4TFR100-250-R30 fig.2 N 3.0 4TFK100-150 fig.2 N 15 S 4TFR120-260-R05 fig.2 N 0.5 4TFK100-250 fig.2 N 10.0 -0.005 25 M - - 10 80 4 4TFR120-260-R10 fig.2 N 1.0 -0.025 -0.010 4TFK100-330 fig.2 N 33 L 4TFR120-260-R15 fig.2 N 12.0 -0.030 1.5 26 - - 12 100 4 4TFK120-180 fig.2 N 18 S 4TFR120-260-R20 fig.2 N 2.0 4TFK120-260 fig.2 N 12.0 -0.010 26 M - - 12 100 4 4TFR120-260-R30 fig.2 N 3.0 -0.030 4TFK120-360 fig.2 N 36 L 4TFR160-350-R10 fig.2 N 1.0 4TFK160-240 fig.2 N 24 S 4TFR160-350-R20 fig.2 N 16.0 -0.010 2.0 35 - - 16 110 4 -0.010 -0.030 4TFK160-350 fig.2 N 16.0 -0.030 35 M - - 16 110 4 4TFR160-350-R30 fig.2 N 3.0 4TFK160-480 fig.2 N 48 L 4TFR200-450-R10 fig.2 N 1.0 4TFK200-300 fig.2 N -0.010 30 S 4TFR200-450-R20 fig.2 N 20.0 -0.010 2.0 45 - - 20 125 4 20.0 -0.030 - - 20 125 4 -0.030 4TFK200-450 fig.2 N 45 M 4TFR200-450-R30 fig.2 N 3.0 *Applications for each cutting edge length Recommended Cutting Conditions L61 } S :Short ・・・ Shouldering Slotting M : Medium L :Long・・・・・・ Shouldering ●:Std. Item L23