Основной каталог Kyocera 2016-2017 - страница 593

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

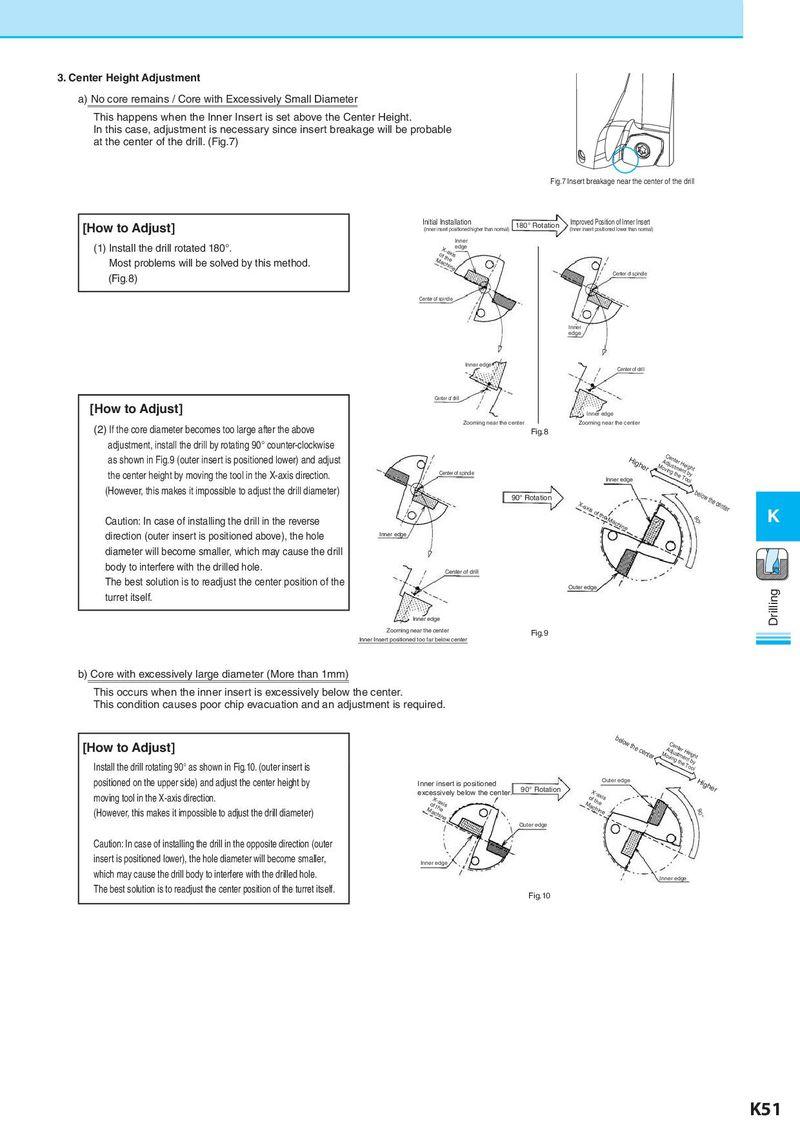

3. Center Height Adjustment a) No core remains / Core with Excessively Small Diameter This happens when the Inner Insert is set above the Center Height. In this case, adjustment is necessary since insert breakage will be probable at the center of the drill. (Fig.7) Fig.7 Insert breakage near the center of the drill [How to Adjust] Initial Installation 180° Rotation Improved Position of Inner Insert (Inner insert positioned higher than normal) (Inner insert positioned lower than normal) Inner (1) Install the drill rotated 180°. MoaXfct-hhaiexniesedge Most problems will be solved by this method. (Fig.8) Center of spindle Center of spindle Inner edge Inner edge Center of drill Center of drill [How to Adjust] Inner edge (2) If the core diameter becomes too large after the above Zooming near the center Zooming near the center Fig.8 adjustment, install the drill by rotating 90° counter-clockwise as shown in Fig.9 (outer insert is positioned lower) and adjust Higher MoAvCdinjeugnstttemhreeHnTetoibogylht the center height by moving the tool in the X-axis direction. Center of spindle Inner edge (However, this makes it impossible to adjust the drill diameter) 90° Rotation below the center Caution: In case of installing the drill in the reverse X-axis of the Machine 90° K direction (outer insert is positioned above), the hole Inner edge diameter will become smaller, which may cause the drill body to interfere with the drilled hole. Center of drill The best solution is to readjust the center position of the Outer edge turret itself. Drilling Inner edge Zooming near the center Fig.9 Inner Insert positioned too far below center b) Core with excessively large diameter (More than 1mm) This occurs when the inner insert is excessively below the center. This condition causes poor chip evacuation and an adjustment is required. [How to Adjust] below the center MoAvdCinjeugnstttmehreeHnTetoibogylht Install the drill rotating 90° as shown in Fig.10. (outer insert is positioned on the upper side) and adjust the center height by Inner insert is positioned Outer edge Higher excessively below the center. 90° Rotation MoafXcth-haienxeis moving tool in the X-axis direction. MoaXfct-hhaiexnies (However, this makes it impossible to adjust the drill diameter) 90° Outer edge Caution: In case of installing the drill in the opposite direction (outer insert is positioned lower), the hole diameter will become smaller, Inner edge which may cause the drill body to interfere with the drilled hole. Inner edge The best solution is to readjust the center position of the turret itself. Fig.10 K51