Основной каталог Kyocera 2016-2017 - страница 559

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

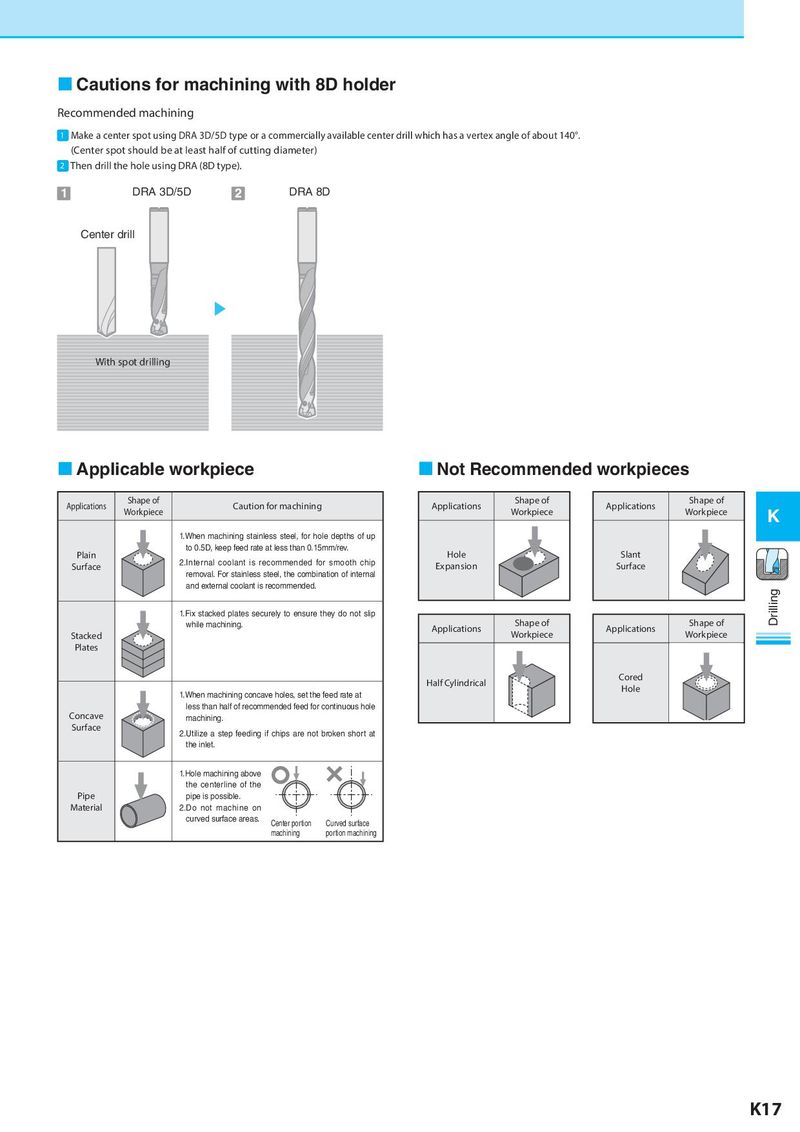

Cautions for machining with 8D holder Recommended machining 1 Make a center spot using DRA 3D/5D type or a commercially available center drill which has a vertex angle of about 140°. (Center spot should be at least half of cutting diameter) 2 Then drill the hole using DRA (8D type). 1 DRA 3D/5D 2 DRA 8D Center drill With spot drilling Applicable workpiece Not Recommended workpieces Applications Shape of Caution for machining Applications Shape of Applications Shape of Workpiece Workpiece Workpiece K 1.When machining stainless steel, for hole depths of up to 0.5D, keep feed rate at less than 0.15mm/rev. Hole Slant Plain 2.Internal coolant is recommended for smooth chip Surface removal. For stainless steel, the combination of internal Expansion Surface and external coolant is recommended. Drilling 1.Fix stacked plates securely to ensure they do not slip while machining. Applications Shape of Applications Shape of Stacked Workpiece Workpiece Plates Half Cylindrical Cored 1.When machining concave holes, set the feed rate at Hole less than half of recommended feed for continuous hole Concave machining. Surface 2.Utilize a step feeding if chips are not broken short at the inlet. 1.Hole machining above the centerline of the Pipe pipe is possible. Material 2.Do not machine on curved surface areas. Center portion Curved surface machining portion machining K17