Основной каталог Kyocera 2016-2017 - страница 558

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

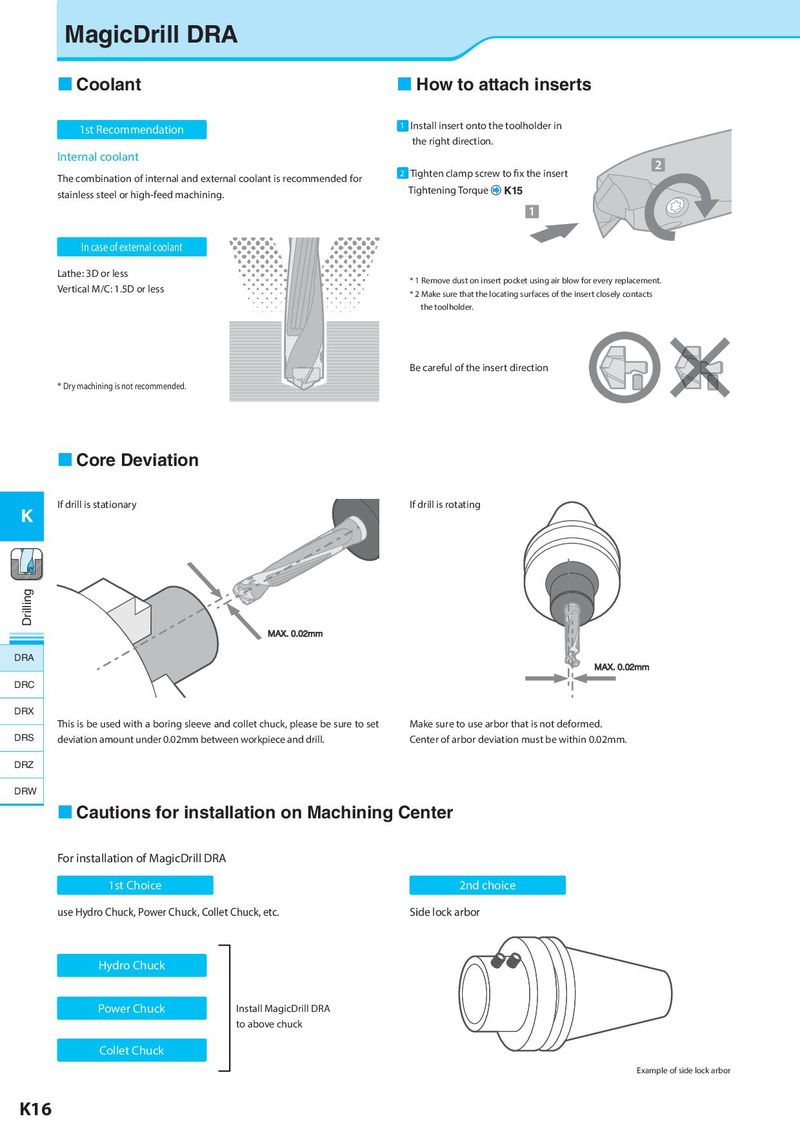

MagicDrill DRA Coolant How to attach inserts 1st Recommendation 1 Install insert onto the toolholder in the right direction. Internal coolant 2 The combination of internal and external coolant is recommended for 2 Tighten clamp screw to fix the insert stainless steel or high-feed machining. Tightening Torque K15 1 In case of external coolant Lathe: 3D or less * 1 Remove dust on insert pocket using air blow for every replacement. Vertical M/C: 1.5D or less * 2 Make sure that the locating surfaces of the insert closely contacts the toolholder. Be careful of the insert direction * Dry machining is not recommended. Core Deviation K If drill is stationary If drill is rotating Drilling MAX. 0.02mm DRA MAX. 0.02mm DRC DRX This is be used with a boring sleeve and collet chuck, please be sure to set Make sure to use arbor that is not deformed. DRS deviation amount under 0.02mm between workpiece and drill. Center of arbor deviation must be within 0.02mm. DRZ DRW Cautions for installation on Machining Center For installation of MagicDrill DRA 1st Choice 2nd choice use Hydro Chuck, Power Chuck, Collet Chuck, etc. Side lock arbor Hydro Chuck Power Chuck Install MagicDrill DRA to above chuck Collet Chuck Example of side lock arbor K16